- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

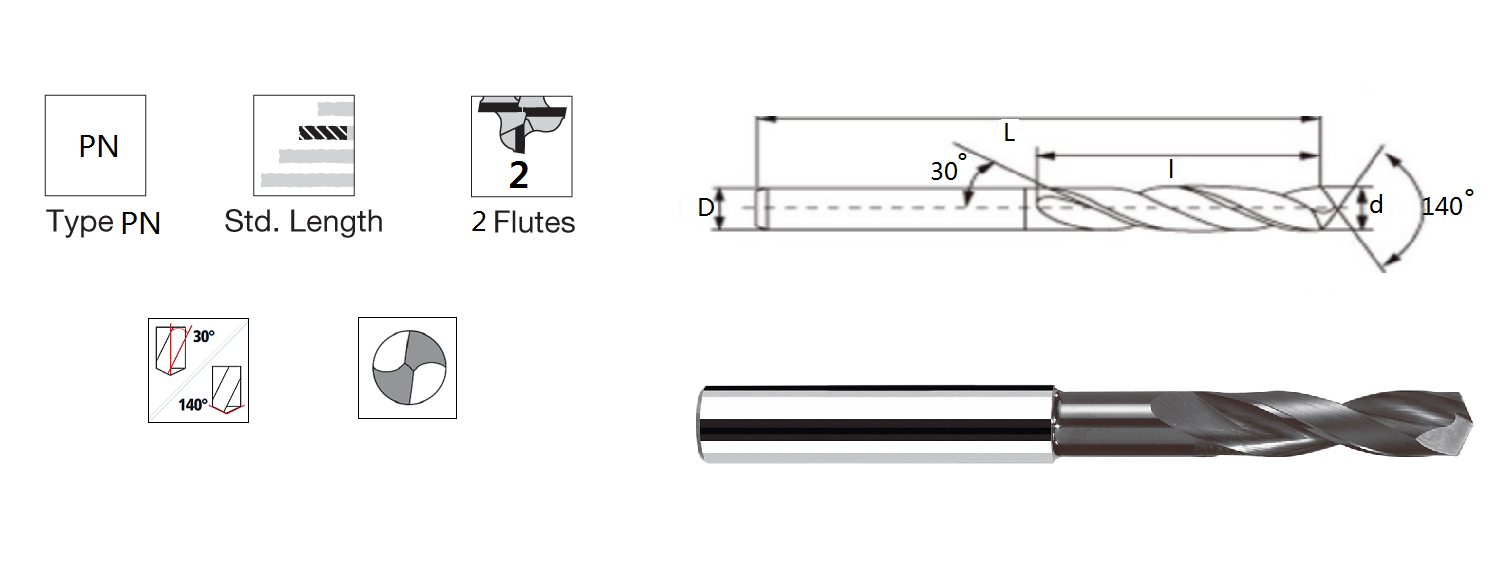

硬质合金外冷钻头

外冷钻

HJDK550系列-外冷钻

适用于钢、不锈钢、铸铁、有色金属材料的钻孔。

纳米涂层AlTiN

材料 : 碳化钨

文字说明:

HJDK550钻头是为钢材的复杂加工而开发的。它以其高切削价值和始终如一的良好孔质量给人留下深刻印象。由于特殊的微观几何形状,产生了特别稳定和精确的切削刃。它的腹板变薄和凹槽轮廓的极其光滑的表面光洁度减少了钻头和切屑之间的摩擦。加工温度降低,排屑效果改善。切削力降低。这些刀具特性可实现最高的孔质量和刀具寿命。

特征:

适用于钢、不锈钢、铸铁、有色金属材料的钻孔。

短柄凿子,出色的自定心能力。

径向点,切削阻力更小。

唇边倒角,进给率更高,效率更高。

常规尺寸:

硬质合金钻头

| 订购代码 | 外径 | 长笛长度 | 总体长度 | 柄径 |

| (四) | (l) | (大) | (四) | |

| HJDK550-005S | 0.5 | 6 | 26 | 0.5 |

| HJDK550-006S | 0.6 | 6 | 26 | 0.6 |

| HJDK550-007S | 0.7 | 6 | 26 | 0.7 |

| HJDK550-008S | 0.8 | 6 | 26 | 0.8 |

| HJDK550-009S | 0.9 | 6 | 26 | 0.9 |

| HJDK550-0100S | 1 | 6 | 26 | 1 |

| HJDK550-011S | 1.1 | 7 | 28 | 1.1 |

| HJDK550-012S | 1.2 | 8 | 30 | 1.2 |

| HJDK550-013S | 1.3 | 8 | 30 | 1.3 |

| HJDK550-014S | 1.4 | 9 | 32 | 1.4 |

| HJDK550-015S | 1.5 | 9 | 32 | 1.5 |

| HJDK550-016S | 1.6 | 10 | 34 | 1.6 |

| HJDK550-017S | 1.7 | 10 | 34 | 1.7 |

| HJDK550-018S | 1.8 | 11 | 36 | 1.8 |

| HJDK550-019S | 1.9 | 11 | 36 | 1.9 |

| HJDK550-020S | 2 | 12 | 38 | 2 |

| HJDK550-021S | 2.1 | 12 | 38 | 3 |

| HJDK550-022S | 2.2 | 13 | 40 | 3 |

| HJDK550-023S | 2.3 | 13 | 40 | 3 |

| HJDK550-024S | 2.4 | 14 | 43 | 3 |

| HJDK550-025S | 2.5 | 14 | 43 | 3 |

| HJDK550-026S | 2.6 | 14 | 43 | 3 |

| HJDK550-027S | 2.7 | 16 | 46 | 3 |

| HJDK550-028S | 2.8 | 16 | 46 | 3 |

| HJDK550-029S | 2.9 | 16 | 46 | 3 |

| HJDK550-030S | 3 | 16 | 46 | 3 |

| HJDK550-031S | 3.1 | 18 | 49 | 4 |

| HJDK550-032S | 3.2 | 18 | 49 | 4 |

| HJDK550-033S | 3.3 | 18 | 49 | 4 |

| HJDK550-034S | 3.4 | 20 | 52 | 4 |

| HJDK550-035S | 3.5 | 20 | 52 | 4 |

| HJDK550-036S | 3.6 | 20 | 52 | 4 |

| HJDK550-037S | 3.7 | 20 | 52 | 4 |

| HJDK550-038S | 3.8 | 20 | 52 | 4 |

| HJDK550-039S | 3.9 | 22 | 55 | 4 |

| HJDK550-040S | 4 | 22 | 55 | 4 |

| HJDK550-041S | 4.1 | 22 | 55 | 5 |

| HJDK550-042S | 4.2 | 22 | 55 | 5 |

| HJDK550-043S | 4.3 | 22 | 55 | 5 |

| HJDK550-044S | 4.4 | 24 | 55 | 5 |

| HJDK550-045S | 4.5 | 24 | 55 | 5 |

| HJDK550-046S | 4.6 | 24 | 58 | 5 |

| HJDK550-047S | 4.7 | 24 | 58 | 5 |

| HJDK550-048S | 4.8 | 24 | 58 | 5 |

| HJDK550-049S | 4.9 | 26 | 58 | 5 |

| HJDK550 -050S | 5 | 26 | 58 | 5 |

| HJDK550-051S | 5.1 | 26 | 62 | 5.1 |

| HJDK550-052S | 5.2 | 26 | 62 | 5.2 |

| HJDK550-053S | 5.3 | 28 | 62 | 5.3 |

| HJDK550-054S | 5.4 | 28 | 62 | 5.4 |

| HJDK550-055S | 5.5 | 28 | 66 | 5.5 |

| HJDK550-056S | 5.6 | 28 | 66 | 5.6 |

| HJDK550-057S | 5.7 | 28 | 66 | 5.7 |

| HJDK550-058S | 5.8 | 28 | 66 | 5.8 |

| HJDK550-059S | 5.9 | 28 | 66 | 5.9 |

| HJDK550-060S | 6 | 31 | 66 | 6 |

| HJDK550-061S | 6.1 | 31 | 70 | 7 |

| HJDK550-062S | 6.2 | 31 | 70 | 7 |

| HJDK550-063S | 6.3 | 31 | 70 | 7 |

| HJDK550 -064S | 6.4 | 31 | 70 | 7 |

| HJDK550 -065S | 6.5 | 31 | 70 | 7 |

| HJDK550-066S | 6.6 | 31 | 70 | 7 |

| HJDK550-067S | 6.7 | 31 | 70 | 7 |

| HJDK550-068S | 6.8 | 34 | 74 | 7 |

| HJDK550-069S | 6.9 | 34 | 74 | 7 |

| HJDK550-070S | 7 | 34 | 74 | 7 |

| HJDK550-071S | 7.1 | 34 | 74 | 8 |

| HJDK550-072S | 7.2 | 34 | 74 | 8 |

| HJDK550-073S | 7.3 | 34 | 74 | 8 |

| HJDK550-074S | 7.4 | 34 | 74 | 8 |

| HJDK550-075S | 7.5 | 34 | 74 | 8 |

| HJDK550-076S | 7.6 | 37 | 79 | 8 |

| HJDK550-077S | 7.7 | 37 | 79 | 8 |

| HJDK550-078S | 7.8 | 37 | 79 | 8 |

| HJDK550-079S | 7.9 | 37 | 79 | 8 |

| HJDK550-080S | 8 | 37 | 79 | 8 |

| HJDK550-081S | 8.1 | 37 | 79 | 9 |

| HJDK550 -082S | 8.2 | 37 | 79 | 9 |

| HJDK550 -083S | 8.3 | 37 | 79 | 9 |

| HJDK550 -084S | 8.4 | 37 | 79 | 9 |

| HJDK550-085S | 8.5 | 37 | 79 | 9 |

| HJDK550-086S | 8.6 | 40 | 84 | 9 |

| HJDK550-087S | 8.7 | 40 | 84 | 9 |

| HJDK550-088S | 8.8 | 40 | 84 | 9 |

| HJDK550-089S | 8.9 | 40 | 84 | 9 |

| HJDK550-090S | 9 | 40 | 84 | 9 |

| HJDK550-091S | 9.1 | 40 | 84 | 10 |

| HJDK550-092S | 9.2 | 40 | 84 | 10 |

| HJDK550-093S | 9.3 | 40 | 84 | 10 |

| HJDK550-094S | 9.4 | 40 | 84 | 10 |

HJDK550 硬质合金钻头

| 订购代码 | 外径 | 长笛长度 | 总体长度 | 柄径 |

| (四) | (l) | (大) | (四) | |

| HJDK550-095S | 9.5 | 40 | 84 | 10 |

| HJDK550-096S | 9.6 | 43 | 89 | 10 |

| HJDK550-097S | 9.7 | 43 | 89 | 10 |

| HJDK550-098S | 9.8 | 43 | 89 | 10 |

| HJDK550-099S | 9.9 | 43 | 89 | 10 |

| HJDK550-100S | 10 | 43 | 89 | 10 |

| HJDK550-101S | 10.1 | 43 | 89 | 11 |

| HJDK550-102S | 10.2 | 43 | 89 | 11 |

| HJDK550-103S | 10.3 | 43 | 89 | 11 |

| HJDK550-104S | 10.4 | 43 | 89 | 11 |

| HJDK550-105S | 10.5 | 43 | 89 | 11 |

| HJDK550-106S | 10.6 | 43 | 89 | 11 |

| HJDK550-107S | 10.7 | 43 | 89 | 11 |

| HJDK550-108S | 10.8 | 43 | 89 | 11 |

| HJDK550-109S | 10.9 | 43 | 89 | 11 |

| HJDK550-110S | 11 | 47 | 95 | 11 |

| HJDK550-111S | 11.1 | 47 | 95 | 12 |

| HJDK550-112S | 11.2 | 47 | 95 | 12 |

| HJDK550-113S | 11.3 | 47 | 95 | 12 |

| HJDK550-114S | 11.4 | 47 | 95 | 12 |

| HJDK550-115S | 11.5 | 47 | 95 | 12 |

| HJDK550-116S | 11.6 | 47 | 95 | 12 |

| HJDK550-117S | 11.7 | 47 | 95 | 12 |

| HJDK550-118S | 11.8 | 47 | 95 | 12 |

| HJDK550-119S | 11.9 | 47 | 95 | 12 |

| HJDK550-120S | 12 | 51 | 102 | 12 |

| HJDK550-121S | 12.1 | 51 | 102 | 13 |

| HJDK550-122S | 12.2 | 51 | 102 | 13 |

| HJDK550-123S | 12.3 | 51 | 102 | 13 |

| HJDK550-124S | 12.4 | 51 | 102 | 13 |

| HJDK550-125S | 12.5 | 51 | 102 | 13 |

| HJDK550-126S | 12.6 | 51 | 102 | 13 |

| HJDK550-127S | 12.7 | 51 | 102 | 13 |

| HJDK550-128S | 12.8 | 51 | 102 | 13 |

| HJDK550-129S | 12.9 | 51 | 102 | 13 |

| HJDK550-130S | 13 | 51 | 102 | 13 |

HJDK550 标准钻头:

| 订购代码 | 外径 | 长笛长度 |

| (四) | (l) | |

| HJDK550-0030 | 0.3 | 5.5 |

| HJDK550-0035 | 0.35 | 5.5 |

| HJDK550-0040 | 0.4 | 7 |

| HJDK550-0045 | 0.45 | 7 |

| HJDK550-0050 | 0.5 | 8.5 |

| HJDK550-0055 | 0.55 | 8.5 |

| HJDK550-0060 | 0.6 | 9.5 |

| HJDK550-0065 | 0.65 | 9.5 |

| HJDK550-0070 | 0.7 | 9.5 |

| HJDK550-0075 | 0.75 | 9.5 |

| HJDK550-0080 | 0.8 | 9.5 |

| HJDK550-0085 | 0.85 | 9.5 |

| HJDK550-0090 | 0.9 | 9.5 |

| HJDK550-0095 | 0.95 | 9.5 |

| HJDK550-0100 | 1 | 10.5 |

| HJDK550-0105 | 1.05 | 10.5 |

| HJDK550-0110 | 1.1 | 10.5 |

| HJDK550-0115 | 1.15 | 10.5 |

| HJDK550-0120 | 1.2 | 10.5 |

| HJDK550-0125 | 1.25 | 10.5 |

| HJDK550-0130 | 1.3 | 12 |

| HJDK550-0135 | 1.35 | 12 |

| HJDK550-0140 | 1.4 | 12 |

| HJDK550-0145 | 1.45 | 12 |

| HJDK550-0150 | 1.5 | 12 |

| HJDK550-0155 | 1.55 | 12 |

| HJDK550-0160 | 1.6 | 12 |

| HJDK550-0165 | 1.65 | 12 |

| HJDK550-0170 | 1.7 | 12 |

| HJDK550-0175 | 1.75 | 12 |

| HJDK550-0180 | 1.8 | 12 |

| HJDK550-0185 | 1.85 | 12 |

| HJDK550-0190 | 1.9 | 12 |

| HJDK550-0195 | 1.95 | 12 |

| HJDK550-0200 | 2 | 12 |

| HJDK550-0205 | 2.05 | 12 |

| HJDK550-0210 | 2.1 | 12 |

| HJDK550-0215 | 2.15 | 12 |

| HJDK550-0220 | 2.2 | 12 |

| HJDK550-0225 | 2.25 | 12 |

| HJDK550-0230 | 2.3 | 12 |

| HJDK550-0235 | 2.35 | 12 |

| HJDK550-0240 | 2.4 | 12 |

| HJDK550-0245 | 2.45 | 12 |

| HJDK550-0250 | 2.5 | 12 |

| HJDK550-0255 | 2.55 | 12 |

| HJDK550-0260 | 2.6 | 12 |

| HJDK550-0265 | 2.65 | 12 |

| HJDK550-0270 | 2.7 | 12 |

| HJDK550-0275 | 2.75 | 12 |

| HJDK550-0280 | 2.8 | 12 |

| HJDK550-0285 | 2.85 | 12 |

| HJDK550-0290 | 2.9 | 12 |

| HJDK550-0295 | 2.95 | 12 |

| HJDK550-0300 | 3 | 12 |

| HJDK550-0305 | 3.05 | 12 |

| HJDK550-0310 | 3.1 | 12 |

| HJDK550-0315 | 3.15 | 12 |

| HJDK550-03175 | 3.175 | 12 |

我们可以根据客户要求生产3D、5D、8D钻头或定制非标钻头。我们还可以根据客户要求生产非标准立铣刀。

工具材料组成:

1.物理性能:

A) 硬度大于或等于92.8 HRA;

b) 密度大于或等于14.2 g/cm³;

c) TRS大于或等于4200 N/mm²;

D) 无ETA相条件;

e) 不受其他材料污染;

F) 孔隙率 = A00 / B00 / C00 ;

G) 均匀一致的晶粒尺寸。粒度不能大于规定值。

H) 仅碳化铬晶粒生长抑制剂。

2.所有生产工具、涂层均采用德国、瑞士加工设备;

涂层:

纳米涂层AlTiN

特点与作用

1、高铝含量提供优良的热硬性和抗氧化性。

2、特殊方法优化涂层结构,显着提高稳定性,减少表面液滴数量。

| 外冷钻运行参数: | |||||||||||

| 工件材料 | 切割速度 | 进给率(毫米/转) | |||||||||

| (米/分钟) | |||||||||||

| 外部冷却 | D3 | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D18 | D20 | |

| 钻头 | |||||||||||

| 低碳钢,长切屑 | 100 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<125HB) | 80 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| 低碳钢,短切, | 100 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| 易切钢 | 75 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<125HB) | 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| 高碳钢 | 90 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| 和中碳钢 | 70 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<25HRC) | 45 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| 合金钢、工具钢 | 90 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<35HRC) | 70 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 45 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| 合金钢、工具钢 | 80 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| (35-48HRC) | 60 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| 40 | 0.14 | 0.17 | 0.22 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| PH 和铁素体、马氏体钢 | 70 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| (<35HRC) | 50 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| 30 | 0.14 | 0.17 | 0.23 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| 奥氏体不锈钢 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.14 | |

| (130-200HB) | 0.08 | 0.1 | 0.12 | 0.13 | 0.15 | 0.17 | 0.18 | 0.2 | 0.22 | 0.24 | |

| 0.1 | 0.12 | 0.14 | 0.18 | 0.2 | 0.22 | 0.24 | 0.24 | 0.26 | 0.28 | ||

| 高强度奥氏体 | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 | |

| 和锻造不锈钢 | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 | |

| (<25HRC) | 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | |

| 双相不锈钢 | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 | |

| (<30HRC) | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 | |

| 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | ||

| 灰铸铁 | 100 | 0.13 | 0.15 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 |

| (<32HRC) | 80 | 0.17 | 0.02 | 0.26 | 0.32 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | 0.48 |

| 60 | 0.21 | 0.26 | 0.32 | 0.4 | 0.42 | 0.46 | 0.5 | 0.52 | 0.54 | 0.56 | |

| 中等合金铁 | 100 | 0.11 | 0.13 | 0.15 | 0.17 | 0.22 | 0.22 | 0.24 | 0.26 | 0.3 | 0.34 |

| 处理难度, | 80 | 0.15 | 0.18 | 0.23 | 0.26 | 0.28 | 0.34 | 0.35 | 0.4 | 0.4 | 0.43 |

| 球墨铸铁 | 60 | 0.18 | 0.22 | 0.27 | 0.38 | 0.38 | 0.42 | 0.44 | 0.48 | 0.46 | 0.5 |

| (<28HRC) | |||||||||||

| 难处理的高合金铸铁, | 90 | 0.06 | 0.08 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.23 | 0.23 |

| 球墨铸铁 | 70 | 0.09 | 0.1 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.28 | 0.29 |

| (<28HRC) | 60 | 0.11 | 0.13 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.34 | 0.35 |

| 锻造铝合金 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si<12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| 铸铝合金 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si<12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| 铸铝合金 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si>12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| 铜、铜合金 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (<200HB) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

注意力:

确保工件和机器稳定并使用精密夹持器,使用液压夹头,高品质弹簧夹头。

确保总指示跳动 (TIR) 小于 0.02 毫米。

推荐的切割条件适用于应用水溶性。

如果工具尺寸不在表中。请参照表中刀片直径大小选择切削参数,加工时根据实际工况调整切削参数。

公司拥有从粉末原料制备、模具制作、压制、压力烧结、磨削、涂层及涂层后处理的完整叶片制造工艺装备生产线。专注于硬质合金数控刀片的母材、沟槽结构、精密成形及表面涂层的研究与创新,不断提高硬质合金数控刀片的加工效率、使用寿命等切削性能。经过十余年的科研创新,公司掌握了多项自主核心技术,具备自主研发设计能力,可为每位客户提供定制化生产。