- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

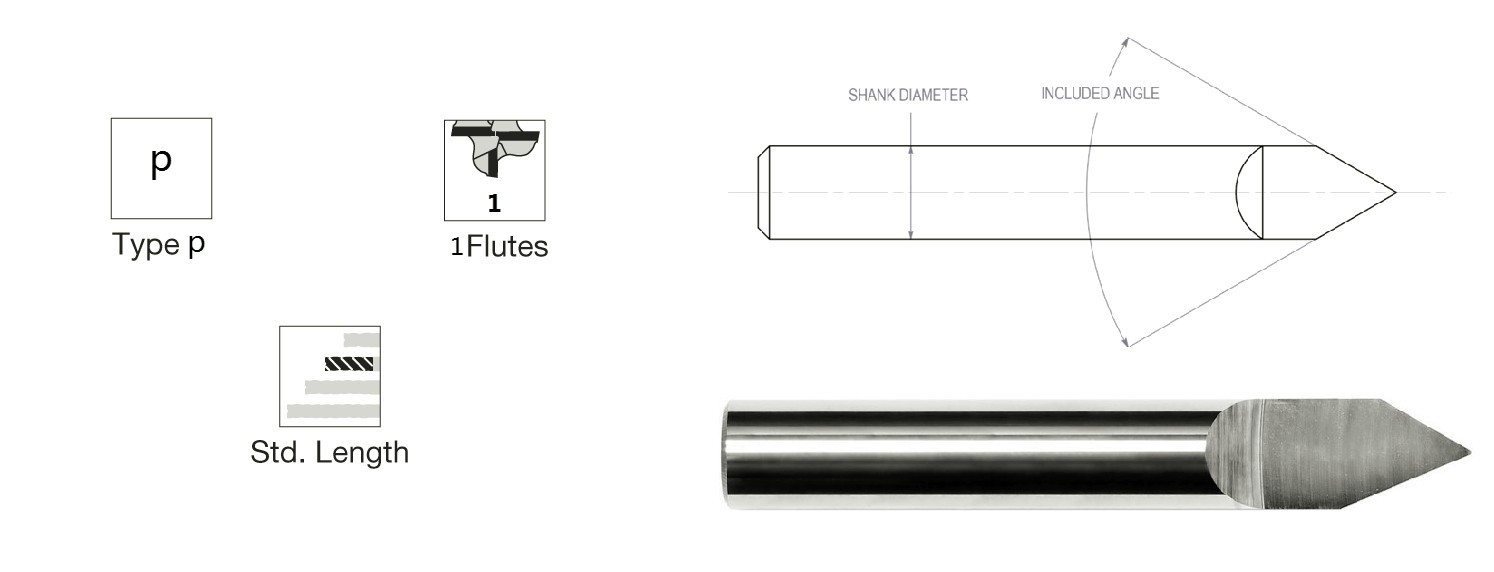

tungsten carbide Datar handap ukiran bit

Datar handap ukiran bit

HJEK550 Datar handap ukiran bit

Aplikasi: Acrylic, PVC, PE, Nilon, Panel komposit Aluminium, kayu gabus, Dua-warna, piring, Acrylic, PVC, Hardwood, MDF

motong, ukiran, panggilingan, relief, jsb

Bahan: tungsten karbida

Pernyataan literal:

Urang mawa rupa-rupa cutters ukiran dina loba ukuran jeung wangun. Nu pang populerna anu cutters tipe satengah buleud. Alat ukiran ieu tiasa dianggo dina rupa-rupa aplikasi ti ngukir plastik dugi ka ngukir baja tahan karat. Pikeun ukiran plastik kami nyarankeun pamotong 50 derajat atanapi 60 derajat. Pencét ukuran alat di handap pikeun harga sareng déskripsi. Pastikeun pikeun milih ukuran tip. Ukuran tip bakal nangtukeun sabaraha lebar garis anjeun, pikeun ukiran karakter leutik milih ukuran tip anu langkung alit.

Ukuran biasa:

| Kode pesenan | Tip W | Sudut A | Diaméter Batang D | Gemblengna Panjang L |

| HJEK550 051001 | 0.1 | 10 | 3.175 | 38.5 |

| HJEK550-051002 | 0.2 | 10 | 3.175 | 38.5 |

| HJEK550-051003 | 0.3 | 10 | 3.175 | 38.5 |

| HJEK550-051501 | 0.1 | 15 | 3.175 | 38.5 |

| HJEK550-051502 | 0.2 | 15 | 3.175 | 38.5 |

| HJEK550-051503 | 0.3 | 15 | 3.175 | 38.5 |

| HJEK550-052001 | 0.1 | 20 | 3.175 | 38.5 |

| HJEK550-052002 | 0.2 | 20 | 3.175 | 38.5 |

| HJEK550-052003 | 0.3 | 20 | 3.175 | 38.5 |

| HJEK550-053001 | 0.1 | 30 | 3.175 | 38.5 |

| HJEK550-053002 | 0.2 | 30 | 3.175 | 38.5 |

| HJEK550-053003 | 0.3 | 30 | 3.175 | 38.5 |

| HJEK550-053004 | 0.4 | 30 | 3.175 | 38.5 |

| HJEK550-053005 | 0.5 | 30 | 3.175 | 38.5 |

| HJEK550-053006 | 0.6 | 30 | 3.175 | 38.5 |

| HJEK550-053008 | 0.8 | 30 | 3.175 | 38.5 |

| HJEK550-053010 | 1 | 30 | 3.175 | 38.5 |

| HJEK550-053015 | 1.5 | 30 | 3.175 | 38.5 |

| HJEK550-053020 | 2 | 30 | 3.175 | 38.5 |

| HJEK550-054501 | 0.1 | 45 | 3.175 | 38.5 |

| HJEK550-054502 | 0.2 | 45 | 3.175 | 38.5 |

| HJEK550-054503 | 0.3 | 45 | 3.175 | 38.5 |

| HJEK550-054505 | 0.5 | 45 | 3.175 | 38.5 |

| HJEK550-056001 | 0.1 | 60 | 3.175 | 38.5 |

| HJEK550-056002 | 0.2 | 60 | 3.175 | 38.5 |

| HJEK550-056003 | 0.3 | 60 | 3.175 | 38.5 |

| HJEK550-056004 | 4 | 60 | 3.175 | 38.5 |

| HJEK550-056005 | 0.5 | 60 | 3.175 | 38.5 |

| HJEK550-059001 | 0.1 | 90 | 3.175 | 38.5 |

| HJEK550-059002 | 2 | 90 | 3.175 | 38.5 |

| HJEK550-059003 | 3 | 90 | 3.175 | 38.5 |

| HJEK550-0542001 | 0.1 | 20 | 4 | 45 |

| HJEK550 0S42002 | 2 | 20 | 4 | 45 |

| HJEK550-0542003 | 3 | 20 | 4 | 45 |

| HJEK550-0543001 | 0.1 | 30 | 4 | 40 |

| HJEK550-0543002 | 0.2 | 30 | 4 | 40 |

| HJEK550-0543003 | 3 | ao | 4 | 40 |

| HJEK550-0543004 | 4 | 30 | 4 | 40 |

| HJEK550-0543005 | 5 | 30 | 4 | 40 |

| HJEK550-0543006 | 0.6 | 30 | 4 | 40 |

| HJEK550-0543008 | 0.8 | 30 | 4 | 40 |

| HJEK550-0544501 | 0.1 | 45 | 4 | 40 |

| HJEK550-0S44502 | 0.2 | 45 | 4 | 40 |

| HJEK550-0544503 | 0.3 | 45 | 4 | 40 |

| HJEK550-0944504 | 0.4 | 45 | 4 | 40 |

| HJEK550-0544505 | 0.5 | 45 | 4 | 40 |

| HJEK550-0544506 | 0.6 | 30 | 4 | 40 |

| HJEK550-0546001 | 0.1 | 60 | 4 | 40 |

| HJEK550-0546002 | 0.2 | 60 | 4 | 40 |

| HJEK550-0546003 | 0.3 | 60 | 4 | 40 |

| HJEK550-0546004 | 0.4 | 60 | 4 | 40 |

| HJEK550-0549001 | 0.1 | 90 | 4 | 40 |

| HJEK550-0549002 | 0.2 | 90 | 4 | 40 |

| HJEK550-0549003 | 0.3 | 90 | 4 | 40 |

| HJEK550-0562001 | 0.1 | 20 | 6 | 50 |

| HJEK550-0562002 | 0.2 | 20 | 6 | 50 |

| HJEK550-0562003 | 0.3 | 20 | 6 | 50 |

| HJEK550-0563001 | 0.1 | 30 | 6 | 45 |

| HJEK550-0563002 | 0.2 | 30 | 6 | 45 |

| HJEK550-0563003 | 0.3 | 30 | 6 | 45 |

| HJEK550-0564501 | 0.1 | 45 | 6 | 45 |

| HJEK550-0564502 | 0.2 | 45 | 6 | 45 |

| HJEK550-0564503 | 0.3 | 45 | 6 | 45 |

| HJEK550-0566001 | 0.1 | 60 | 6 | 45 |

| HJEK550-0566002 | 0.2 | 60 | 6 | 45 |

| HJEK550-0566003 | 0.3 | 60 | 6 | 45 |

| HJEK550-0569001 | 0.1 | 90 | 6 | 45 |

| HJEK550-0569002 | 0.2 | 90 | 6 | 45 |

| HJEK550-0569003 | 0.3 | 90 | 6 | 45 |

| HJEK550-05612001 | 0.1 | 120 | 6 | 45 |

| HJEK550-05612002 | 0.2 | 120 | 6 | 45 |

| HJEK550-0589001 | 0.1 | 90 | 8 | 50 |

| HJEK550-0589002 | 0.2 | 90 | 10 | 50 |

| HJEK550-05129001 | 0.1 | 90 | 12 | 50 |

| HJEK550-05129002 | 0.2 | 90 | 12 | 50 |

| HJEK550-05149001 | 0.1 | 90 | 14 | 50 |

| HJEK550-05149002 | 0.2 | 90 | 14 | 50 |

Komposisi bahan alat:

1.Sipat Fisik:

A) Teu karasa leuwih gede atawa sarua jeung 92,6 HRA;

B) Kapadetan leuwih gede atawa sarua jeung 14.4g/cm³;

C) TRS leuwih gede atawa sarua jeung 3800 N/mm²;

D) Bébas tina kaayaan fase ETA;

E) Taya kontaminasi ku bahan séjén;

F) Porositas = A02/ B00 / C00 ;

G) Ukuran sisikian seragam jeung konsisten. Teu aya ukuran butir anu tiasa langkung ageung tibatan anu ditangtukeun.

H) Inhibitor pertumbuhan gandum kromium karbida wungkul.

2.All parabot produksi, coatings dipaké di Jerman, Swiss, alat-alat ngolah;

3.It urang diusulkeun motong kirang ti 55HRC;

Perhatosan:

Pastikeun sapotong karya jeung mesin anu stabil sarta ngagunakeun wadah precision.

Mangga saluyukeun speed, feed jeung motong jero nurutkeun kaayaan motong sabenerna.

Kaayaan panggilingan nyaéta pikeun ngagiling tungtung dimana panjangna overhang alat kirang ti 4 * D (diaméter gilinding). Nalika alat overhang panjangna leuwih panjang, mangga saluyukeun speed, feed jeung motong jero.

Pausahaan ngabogaan sabeulah lengkep garis produksi parabot prosés manufaktur tina bubuk persiapan bahan baku, pembuatan kapang, mencét, tekanan sintering, grinding, palapis jeung palapis pos-perlakuan. Ieu museurkeun kana panalungtikan sarta inovasi tina bahan dasar, struktur alur, precision ngabentuk jeung palapis permukaan carbide NC inserts, sarta terus ngaronjatkeun efisiensi machining, hirup layanan sarta sipat motong séjén tina carbide NC inserts. Saatos langkung ti sapuluh taun panalungtikan ilmiah sareng inovasi, perusahaan parantos ngawasa sababaraha téknologi inti mandiri, gaduh kamampuan R&D sareng desain mandiri, sareng tiasa nyayogikeun produksi khusus pikeun unggal palanggan.