- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

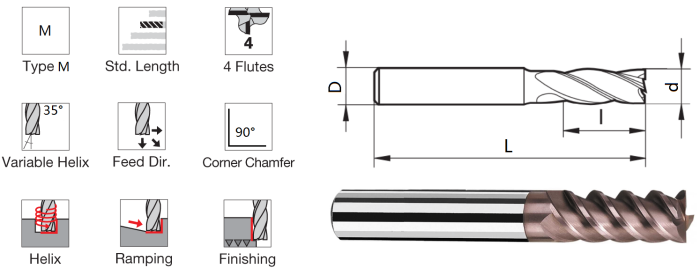

F4 End mill for High Efficiency Machining of Stainless Steel

HJS650 series - High Efficiency Machining of Stainless Steel

HJS650 series - High Efficiency Machining of Stainless Steel

Suitable for rough milling, semi-finishing and finishing of stainless steel (<280HB)

Universal High Performance Coating AlCrSiN

F4

Literal statement:

The structure of Iphone 8 is used 316L stainless steel. This material is more difficult to cut than the 304 stainless steel. Especially the suppliers of Apple Inc. use MIM processing of small accessories, the previous endmills has been unable to meet their needs. Our team has adopted special ultra-fine grain tungsten carbide, special spiral angle, special cutting edge design and Nano AlCrSiN, the product has a perfect success, and has won high praise from FOXCNN and MiYa.

Features:

Suitable for rough milling, semi-finishing and finishing of stainless steel (<280HB).

Design for the small depth/large width in face milling, large depth/small width in side milling, less than 0.3D in shallow slotting.

Water soluable or oil based are the best cooling methods.

Regular size:

| Ordering code | Outside Diameter | Flute Length | Overall Length | Shank Diameter |

| (d) | (l) | (L) | (D) | |

| HJS650-4F-D010-L050 | 1.0 | 3.0 | 50 | 4 |

| HJS650-4F-D015-L050 | 1.5 | 4.5 | 50 | 4 |

| HJS650-4F-D020-L050 | 2.0 | 6.0 | 50 | 4 |

| HJS650-4F-D025-L050 | 2.5 | 7.0 | 50 | 4 |

| HJS650-4F-D030-L050 | 3.0 | 8.0 | 50 | 4 |

| HJS650-4F-D035-L050 | 3.5 | 10.0 | 50 | 4 |

| HJS650-4F-D040-L050 | 4.0 | 11.0 | 50 | 4 |

| HJS650-4F-D050-L050 | 5.0 | 13.0 | 50 | 6 |

| HJS650-4F-D060-L050 | 6.0 | 16.0 | 50 | 6 |

| HJS650-4F-D070-L060 | 7.0 | 17.0 | 60 | 8 |

| HJS650-4F-D080-L060 | 8.0 | 20.0 | 60 | 8 |

| HJS650-4F-D090-L075 | 9.0 | 25.0 | 75 | 10 |

| HJS650-4F-D100-L075 | 10.0 | 25.0 | 75 | 10 |

| HJS650-4F-D110-L075 | 11.0 | 28.0 | 75 | 12 |

| HJS650-4F-D120-L075 | 12.0 | 30.0 | 75 | 12 |

| HJS650-4F-D140-L080 | 14.0 | 35.0 | 80 | 14 |

| HJS650-4F-D160-L100 | 16.0 | 45.0 | 100 | 16 |

| HJS650-4F-D180-L100 | 18.0 | 48.0 | 100 | 18 |

| HJS650-4F-D200-L100 | 20.0 | 50.0 | 100 | 20 |

Operation parameter:

| HJS600 S4 For Stainless Steels-Side Milling | ||||||||||||||

| Grades | Tool shape | Workpiece | Cutting Depth | VC m/min | Tool Diameter | 1 | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| S4 | Material | (mm) | (mm) | |||||||||||

| DLTUS600 | Square、 | Stainless steel | ap≤1D | 100 | Speed | 25000 | 15900 | 7960 | 5300 | 3980 | 3180 | 2650 | 1990 | 1590 |

| Corner radius | (80-120) | (min-1) | ||||||||||||

| ae≤0.1D | Feed Speed | 700 | 635 | 700 | 680 | 730 | 660 | 600 | 490 | 460 | ||||

| (mm/min) | ||||||||||||||

Tool material composition:

1. Physical Properties:

a. Hardness greater than or equal to 94 HRA;

b. Density greater than or equal to 14.6g/cm³;

c. TRS greater than or equal to 4100 N/mm²;

d. Free of ETA phase condition;

e. No contamination by other materials;

f. Porosity = A00/ B00 / C00 ;

g. Uniform and consistent grain size. No grain size can be larger than specified.

h. Chromium carbide grain growth inhibitor only.

2. All the tools of production, coatings are used in Germany, Switzerland, processing equipment;

Coating:

Universal High Performance Coating AlCrSiN

Characteristics and Function

1、Productivity increase due to significantly higher cutting speed and feed for applications in a wide range of materials.Significantly enhanced productivity.

2、Particular design of structure brings good balance between toughness,thermo-shock stability and residual stress.

Operation parameter:

| HJS650 Stainless steel operation parameter: | ||||||||||||

| HJS650 S4 For Stainless Steels-Side Milling | ||||||||||||

| Grades | Tool shapeS4 | Workpiece Material | Cutting Depth | VC m/min | Tool Diameter(mm) | 1 | 2 | 4 | 6 | 8 | 10 | 12 |

| HJS650 | Square | Stainless steel | ap≤1D | 100 (80-120) | Speed(min-1) | 20000 | 15900 | 7960 | 5300 | 3980 | 3180 | 2650 |

| ae≤0.1D | Feed speed(mm/min) | 960 | 950 | 1110 | 950 | 950 | 890 | 850 | ||||

| HJS650 Stainless steel operation parameter: | ||||||||||||

| HJS650 S4 For Stainless Steels-Slotting | ||||||||||||

| Grades | Tool shape S4 | Workpiece Material | Cutting depth(mm) | VC m/min | Tool Diameter(mm) | 1 | 2 | 4 | 6 | 8 | 10 | 12 |

| DLTUS650 | Square | Stainless steel | ap≤0.3D | 45 | Speed(min-1) | 14300 | 7160 | 3580 | 2390 | 1790 | 1400 | 1200 |

| (35-55) | ||||||||||||

| ae≤1D | Feed speed(mm/min) | 340 | 250 | 215 | 300 | 300 | 300 | 300 | ||||

Attention:

Make sure work piece and machine are stable and use a precision holder.

Please adjust the speed,feed and cutting depth according to actual cutting conditions.

The milling conditiongs are for an End mill where the tool overhang length is less than 4*D(mill dia). When the tool overhang length is longer, please adjust the speed,feed and cutting depth.

The company has a complete blade manufacturing process equipment production line from powder raw material preparation, mold making, pressing, pressure sintering, grinding, coating and coating post-treatment. It focuses on the research and innovation of the base material, groove structure, precision forming and surface coating of carbide NC inserts, and constantly improves the machining efficiency, service life and other cutting properties of carbide NC inserts. After more than ten years of scientific research and innovation, the company has mastered a number of independent core technologies, has independent R&D and design capabilities, and can provide customized production for each customer.