- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

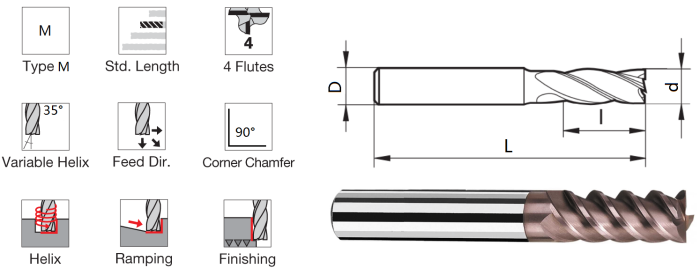

F4 Ipari ọlọ fun Ṣiṣe ṣiṣe giga ti Irin Alagbara

HJS650 jara - Ga ṣiṣe Machining ti Irin alagbara, irin

HJS650 jara - Ga ṣiṣe Machining ti Irin alagbara, irin

Dara fun milling inira, ologbele-ipari ati ipari ti irin alagbara (

Universal High Performance Coating AlCrSiN

F4

Gbólóhùn gidi:

Ilana ti Ipad 8 jẹ irin alagbara 316L. Ohun elo yii nira pupọ lati ge ju 304 irin alagbara irin lọ. Paapa awọn olupese ti Apple Inc. lo MIM ṣiṣiṣẹsẹhin awọn ẹya ẹrọ kekere, awọn ile-igbẹhin iṣaaju ti ko lagbara lati pade awọn iwulo wọn. Ẹgbẹ wa ti gba pataki ultra-fine ọkà tungsten carbide, igun ajija pataki, apẹrẹ gige gige pataki ati Nano AlCrSiN, ọja naa ni aṣeyọri pipe, ati pe o ti gba iyin giga lati FOXCNN ati MiYa.

Awọn ẹya:

Dara fun ọlọ aini inira, ipari-ipari ati ipari ti irin alagbara (

Apẹrẹ fun awọn kekere ijinle / tobi iwọn ni oju milling, nla ijinle / kekere iwọn ni ẹgbẹ milling, kere ju 0.3D ni aijinile slotting.

Omi soluable tabi orisun epo jẹ awọn ọna itutu agbaiye ti o dara julọ.

Iwọn deede:

| Nbere koodu | Ode Opin | Gigun fèrè | Lapapọ Gigun | Opin Shank |

| (d) | (l) | (L) | (D) | |

| HJS650-4F-D010-L050 | 1.0 | 3.0 | 50 | 4 |

| HJS650-4F-D015-L050 | 1.5 | 4.5 | 50 | 4 |

| HJS650-4F-D020-L050 | 2.0 | 6.0 | 50 | 4 |

| HJS650-4F-D025-L050 | 2.5 | 7.0 | 50 | 4 |

| HJS650-4F-D030-L050 | 3.0 | 8.0 | 50 | 4 |

| HJS650-4F-D035-L050 | 3.5 | 10.0 | 50 | 4 |

| HJS650-4F-D040-L050 | 4.0 | 11.0 | 50 | 4 |

| HJS650-4F-D050-L050 | 5.0 | 13.0 | 50 | 6 |

| HJS650-4F-D060-L050 | 6.0 | 16.0 | 50 | 6 |

| HJS650-4F-D070-L060 | 7.0 | 17.0 | 60 | 8 |

| HJS650-4F-D080-L060 | 8.0 | 20.0 | 60 | 8 |

| HJS650-4F-D090-L075 | 9.0 | 25.0 | 75 | 10 |

| HJS650-4F-D100-L075 | 10.0 | 25.0 | 75 | 10 |

| HJS650-4F-D110-L075 | 11.0 | 28.0 | 75 | 12 |

| HJS650-4F-D120-L075 | 12.0 | 30.0 | 75 | 12 |

| HJS650-4F-D140-L080 | 14.0 | 35.0 | 80 | 14 |

| HJS650-4F-D160-L100 | 16.0 | 45.0 | 100 | 16 |

| HJS650-4F-D180-L100 | 18.0 | 48.0 | 100 | 18 |

| HJS650-4F-D200-L100 | 20.0 | 50.0 | 100 | 20 |

paramita isẹ́:

| HJS600 S4 For Stainless Steels-Side Milling | ||||||||||||||

| Awọn ipele | Apẹrẹ irinṣẹ | Iṣẹ iṣẹ | Ijinle gige | VC m/min | Irin Opin | 1 | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| S4 | Ohun elo | (mm) | (mm) | |||||||||||

| DLTUS600 | Square, | Irin ti ko njepata | ap≤1D | 100 | Iyara | 25000 | 15900 | 7960 | 5300 | 3980 | 3180 | 2650 | 1990 | 1590 |

| Rediosi igun | (80-120) | (min-1) | ||||||||||||

| ae≤0.1D | Iyara kikọ sii | 700 | 635 | 700 | 680 | 730 | 660 | 600 | 490 | 460 | ||||

| (mm/min) | ||||||||||||||

Iṣakojọpọ ohun elo irinṣẹ:

1. Awọn ohun-ini ti ara:

a. Lile ti o tobi ju tabi dogba si 94 HRA;

b. iwuwo tobi ju tabi dogba si 14.6g/cm³;

c. TRS tobi ju tabi dọgba si 4100 N/mm²;

d. Ọfẹ ti ipo alakoso ETA;

e. Ko si ibajẹ nipasẹ awọn ohun elo miiran;

f. Porosity = A00/B00 / C00;

g. Aṣọ ati ki o dédé ọkà iwọn. Ko si iwọn ọkà le jẹ tobi ju pato lọ.

h. Chromium carbide onidalẹkun idagbasoke ọkà nikan.

2. Gbogbo awọn irinṣẹ ti iṣelọpọ, awọn aṣọ ti a lo ni Germany, Switzerland, ohun elo ṣiṣe;

Aso:

Universal High Performance Coating AlCrSiN

Abuda ati Išė

1, Imudara iṣelọpọ nitori iyara gige ti o ga pupọ ati ifunni fun awọn ohun elo ni ọpọlọpọ awọn ohun elo.

2, Apẹrẹ pataki ti eto mu iwọntunwọnsi to dara laarin toughness, iduroṣinṣin-mọnamọna ati aapọn to ku.

paramita isẹ́:

| HJS650 Aláwọlé irin paramita isẹ́: | ||||||||||||

| HJS650 S4 Fun Irin Alagbara-Ẹgbẹ Milling | ||||||||||||

| Awọn ipele | Tool shapeS4 | Ohun elo Iṣẹ | Ijinle gige | VC m/iṣẹju | Irin Diatre(mm) | 1 | 2 | 4 | 6 | 8 | 10 | 12 |

| HJS650 | Onigun mẹrin | Irin ti ko njepata | ap≤1D | 100 (80-120) | Speed(min-1) | 20000 | 15900 | 7960 | 5300 | 3980 | 3180 | 2650 |

| ae≤0.1D | Iyara ifunni (mm/min) | 960 | 950 | 1110 | 950 | 950 | 890 | 850 | ||||

| HJS650 Aláwọlé irin paramita isẹ́: | ||||||||||||

| HJS650 S4 Fun Iwọn Alagbara Iho-Iho | ||||||||||||

| Awọn ipele | Tool shape S4 | Ohun elo Iṣẹ | Ijinle (mm) | VC m/iṣẹju | Irin Opin (mm) | 1 | 2 | 4 | 6 | 8 | 10 | 12 |

| DLTUS650 | Onigun mẹrin | Irin ti ko njepata | ap≤0.3D | 45 | Speed(min-1) | 14300 | 7160 | 3580 | 2390 | 1790 | 1400 | 1200 |

| (35-55) | ||||||||||||

| ae≤1D | Iyara kikọ sii (mm/min) | 340 | 250 | 215 | 300 | 300 | 300 | 300 | ||||

Ifarabalẹ:

Rii daju pe nkan iṣẹ ati ẹrọ jẹ iduroṣinṣin ati lo dimu konge.

Jọwọ ṣatunṣe iyara, ifunni ati ijinle gige ni ibamu si awọn ipo gige gangan.

Awọn ipo milling jẹ fun ọlọ ipari nibiti ipari gigun ti ọpa ko kere ju 4 * D (ọlọ dia). Nigbati gigun overhang ọpa ba gun, jọwọ ṣatunṣe iyara, ifunni ati ijinle gige.

Ile-iṣẹ naa ni laini iṣelọpọ ẹrọ iṣelọpọ abẹfẹlẹ pipe lati igbaradi ohun elo aise, ṣiṣe mimu, titẹ, titẹ titẹ, lilọ, ibora ati ibora lẹhin itọju. O fojusi lori iwadi ati ĭdàsĭlẹ ti ipilẹ ohun elo, yara be, konge lara ati dada bo ti awọn ifibọ carbide NC, ati ki o nigbagbogbo mu awọn machining ṣiṣe, iṣẹ aye ati awọn miiran Ige-ini ti carbide NC awọn ifibọ. Lẹhin diẹ sii ju ọdun mẹwa ti iwadii imọ-jinlẹ ati isọdọtun, ile-iṣẹ ti ni oye nọmba kan ti awọn imọ-ẹrọ mojuto ominira, ni R&D ominira ati awọn agbara apẹrẹ, ati pe o le pese iṣelọpọ ti adani fun alabara kọọkan.