- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

HJDK650 Tungsten iziko carbide drills

Iziko le-tungsten carbide drills

HJDK650 Tungsten iziko carbide drills

Ifanele ukubhobhoza intsimbi, insimbi engenasici, intsimbi ekhandiweyo, izinto ezingenayo i-ferrous.

Ubunzima HRA92.8

Izinto eziphathekayo: tungsten carbide

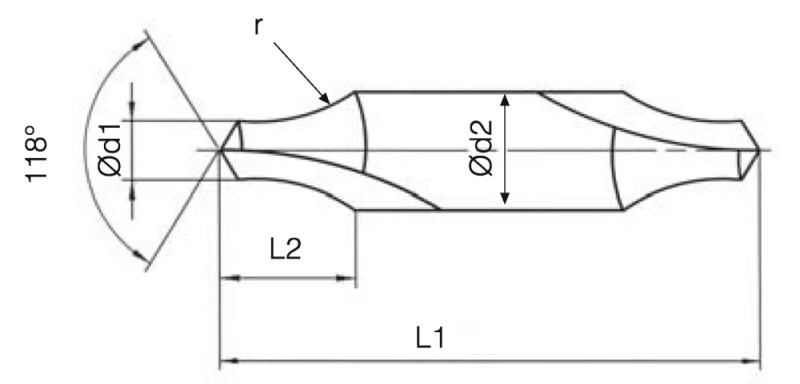

HJDK650 series-ziko uqheliso

Ingxelo yenyani:

I-HJDK650 i-drill eseziko iqonda indibaniselwano elungileyo phakathi kokuhamba kwetshiphu kwindawo yokomba kunye naleyo ikwindawo yesinki. Iifluti zabo ziyakwazi ukuhlalisa ngokupheleleyo iitshiphusi kwaye zisebenze kakuhle ukukhupha iitships.i-drills eziziko zinemida yokusika kuzo zombini iziphelo, kwaye zineflutes ejikelezayo.Ngenxa yokukhupha i-chip elungileyo, iingxaki ezinjalo ziba ngaphantsi njengoko izixhobo ziyaphuka ngenxa ye-chip clogging.Considering drill amandla, siye sacutha ubude drill. Ngaphezulu ukubuyisela ubuthathaka kwindawo yokudibanisa phakathi kwe-drill kunye ne-countersink, indawo yokudibanisa ine-R apho i-radius ingaphakathi kwe-back-taper ye-drill. Kananjalo banoluhlu olubanzi.

Iimbonakalo:

Ifanele ukubhobhoza intsimbi, insimbi engenasici, intsimbi ekhandiweyo, izinto ezingenayo i-ferrous.

Itshiseli yestub, ubuchule obugqwesileyo bokuzibamba.

Inqaku leRadial, ukuchasana kokusika okuncinci.

I-lip chamfer, izinga eliphezulu lokutya, ukusebenza kakuhle okuphezulu.

Ubungakanani obuqhelekileyo:HJDK650 Fine Powder Centre Drill Series

| Ikhowudi yokuodola | Ububanzi | Iengile | Ubude beFlute | O.A.L. | Shank Dia. |

| HJDK650-0102 | 1 | 60° | 1.5 | 35 | 4 |

| HJDK650-0202 | 2 | 60° | 2.5 | 50 | 5 |

| HJDK650-0252 | 2.5 | 60° | 3 1 | 60 | 6.3 |

| HJDK650-03152 | 3.15 | 60° | 3.9 | 70 | 8 |

| HJDK650-0402 | 4 | 60° | 5 | 80 | 10 |

| HJDK650-0502 | 5 | 60° | 6.3 | 80 | 12 |

| HJDK650-0632 | 6.3 | 60° | 80 | 80 | 16 |

Ukuqulunqwa kwezixhobo zesixhobo:

1.Iimpawu zeNdawo:

A) Ubunzima obukhulu kuno okanye obulingana no 92.8 HRA;

B) Uxinzelelo olukhulu kuno okanye olulingana no 14.2 g/cm³;

C) TRS inkulu kuno okanye ilingana no 4200 N/mm²;

D) Isimahla kwimeko yesigaba se-ETA;

E) Akukho ungcoliseko ngezinye izinto;

F) Porosity = A00 / B00 / C00 ;

G) Ubungakanani obufanayo nobungaguquguqukiyo obuziinkozo. Akukho bungakanani benkozo bunokuba bukhulu kunoko buchaziwe.

H) I-Chromium carbide grain growth inhibitor kuphela.

2.Zonke izixhobo zemveliso, iingubo zisetyenziswa eJamani, eSwitzerland, izixhobo zokulungisa;

Ipharamitha yokusebenza:

| Indawo yokubhola ipharamitha yokusebenza: | ||||||||||

| Isixhobo se-Workpeice | Ukusika isantya | Isondlo isantya (mm/rev) | ||||||||

| (m/min) | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D20 | ||

| Low carbon steel, long chip (<125HB) | 130 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.15 | 0.17 | 0.2 | 0.24 | 0.26 | 0.3 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.26 | 0.3 | 0.32 | 0.35 | 0.4 | 0.45 | ||

| Intsimbi yekhabhoni esezantsi, isikwe mfutshane, intsimbi esisikiwe ngokulula ( | 120 | 0.1 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.24 | 0.3 | 0.32 | 0.34 | 0.4 | 0.45 | ||

| Intsimbi ephezulu yekhabhoni kunye nentsimbi yekhabhoni ephakathi ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Intsimbi yentsimbi, isixhobo intsimbi ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Intsimbi yentsimbi, isixhobo intsimbi (35-48HRC) | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| PH kunye ne-ferritic, intsimbi zemartensitic | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Gray iron(<32HRC) | 140 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Ialloyi intsimbi ye phakathi ukucutshungulwa ubunzima, nodular cast intsimbi ( | 130 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 105 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Intsimbi ephezulu yealloyi ephosayo, nodular cast iron | 120 | 0.1 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.28 | |

| 90 | 0.16 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.29 | ||

| 60 | 0.22 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.35 | ||

| I-aluminiyam eyenziwe ngealloyi (Si | 150 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Cast ialuminiyam ingxubevange (Si | 150 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 120 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Cast ialuminiyam ingxubevange (Si>12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| 12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

Ubhedu, ubhedu ingxubevange (

Ingqalelo:

Qinisekisa ukuba umsebenzi kunye nomatshini uzinzile kwaye usebenzise isibambi esichanekileyo, sebenzisa i-hydraulic chucks, i-collet chucks ephezulu.

Qinisekisa ukuba iyonke ebonisiweyo yokuphuma (TIR) ingaphantsi kwe-0.02mm.

Imeko yokusika ecetyiswayo ifanelekile ukuba ifake i-soluble yamanzi.

Inkampani inomgca opheleleyo wenkqubo yokuvelisa izixhobo ze-blade ukusuka kumgubo wokulungiselela izinto ezikrwada, ukwenza umngundo, ukucinezela, ukucofa uxinzelelo, ukugaya, ukugquma kunye nokugquma emva konyango. Ijolise kuphando kunye nokuveliswa kwezinto ezisisiseko, isakhiwo se-groove, ukuchaneka ukubunjwa kunye nokugubungela umphezulu we-carbide NC inserts, kwaye rhoqo iphucula ukusebenza kakuhle komatshini, ubomi benkonzo kunye nezinye iipropati zokusika ze-carbide NC inserts. Emva kweminyaka engaphezu kweshumi yophando lwezenzululwazi kunye nokusungula izinto ezintsha, inkampani iye yakwazi ubuninzi betekhnoloji engundoqo ezimeleyo, ine-R&D ezimeleyo kunye nobuchule bokuyila, kwaye inokubonelela ngemveliso elungiselelwe umthengi ngamnye.