- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

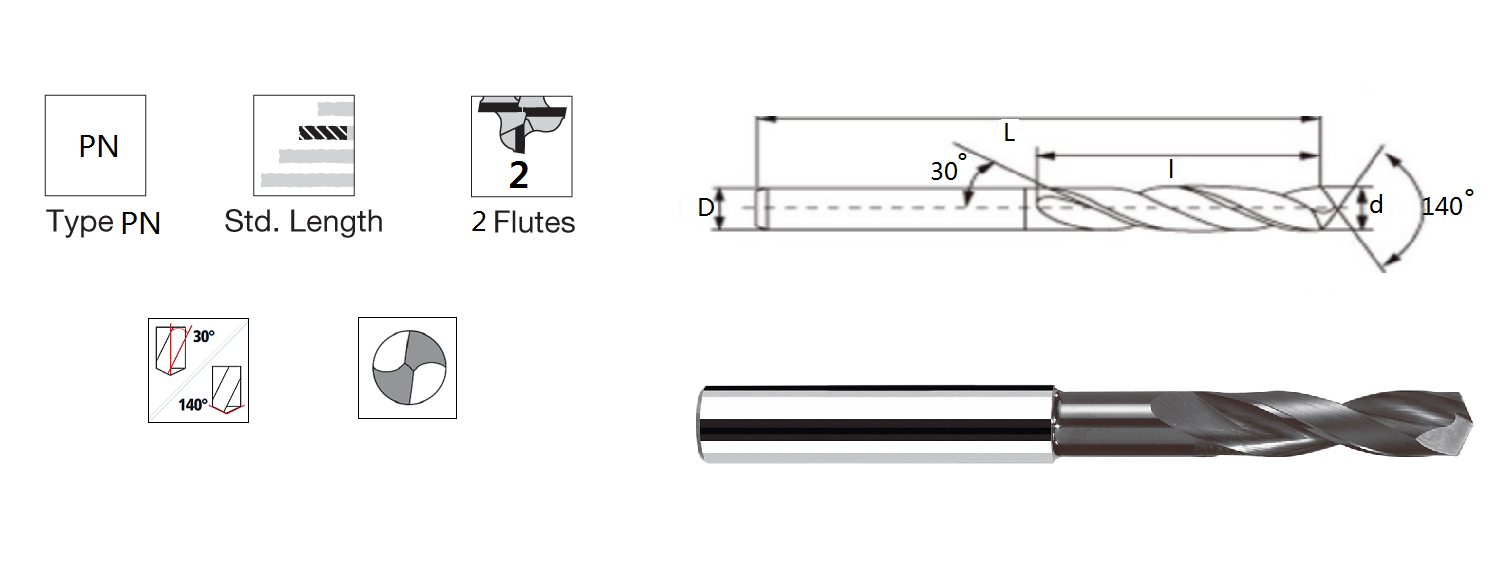

Tungsten carbide bor cooling éksternal

bor cooling éksternal

HJDK550 runtuyan-Éksternal bor cooling

Cocog jeung pangeboran baja, stainless steel, beusi tuang, bahan non-ferrous.

Nano palapis AlTiN

Bahan: tungsten karbida

Pernyataan literal:

HJDK550 bor dikembangkeun pikeun machining kompléks bahan baja. Ayeuna damel gambaran kuat kalawan nilai motong tinggi sarta kualitas liang konsistén alus. Ujung motong utamana stabil sarta akurat dihasilkeun berkat mikro-géométri husus. Lapisan permukaan anu lemes pisan tina ipis wéb sareng profil suling ngirangan gesekan antara bor sareng chip. Suhu machining diréduksi sareng évakuasi chip ningkat. Gaya motong diréduksi. Fitur alat ieu ngahasilkeun kualitas liang maksimum sareng umur alat.

Fitur:

Cocog jeung pangeboran baja, stainless steel, beusi tuang, bahan non-ferrous.

Stub pahat, kamampuhan timer puseur alus teuing.

Titik radial, résistansi motong leutik.

lip chamfer, laju feed luhur, efisiensi luhur.

Ukuran biasa:

Bor Carbide

| Kode pesenan | Luar Diaméterna | Suling Panjang | Gemblengna Panjang | Diaméter Shank |

| (D) | (l) | (L) | (D) | |

| HJDK550-005S | 0.5 | 6 | 26 | 0.5 |

| HJDK550-006S | 0.6 | 6 | 26 | 0.6 |

| HJDK550-007S | 0.7 | 6 | 26 | 0.7 |

| HJDK550-008S | 0.8 | 6 | 26 | 0.8 |

| HJDK550-009S | 0.9 | 6 | 26 | 0.9 |

| HJDK550-0100S | 1 | 6 | 26 | 1 |

| HJDK550-011S | 1.1 | 7 | 28 | 1.1 |

| HJDK550-012S | 1.2 | 8 | 30 | 1.2 |

| HJDK550-013S | 1.3 | 8 | 30 | 1.3 |

| HJDK550-014S | 1.4 | 9 | 32 | 1.4 |

| HJDK550-015S | 1.5 | 9 | 32 | 1.5 |

| HJDK550-016S | 1.6 | 10 | 34 | 1.6 |

| HJDK550-017S | 1.7 | 10 | 34 | 1.7 |

| HJDK550-018S | 1.8 | 11 | 36 | 1.8 |

| HJDK550-019S | 1.9 | 11 | 36 | 1.9 |

| HJDK550-020S | 2 | 12 | 38 | 2 |

| HJDK550-021S | 2.1 | 12 | 38 | 3 |

| HJDK550-022S | 2.2 | 13 | 40 | 3 |

| HJDK550-023S | 2.3 | 13 | 40 | 3 |

| HJDK550-024S | 2.4 | 14 | 43 | 3 |

| HJDK550-025S | 2.5 | 14 | 43 | 3 |

| HJDK550-026S | 2.6 | 14 | 43 | 3 |

| HJDK550-027S | 2.7 | 16 | 46 | 3 |

| HJDK550-028S | 2.8 | 16 | 46 | 3 |

| HJDK550-029S | 2.9 | 16 | 46 | 3 |

| HJDK550-030S | 3 | 16 | 46 | 3 |

| HJDK550-031S | 3.1 | 18 | 49 | 4 |

| HJDK550-032S | 3.2 | 18 | 49 | 4 |

| HJDK550-033S | 3.3 | 18 | 49 | 4 |

| HJDK550-034S | 3.4 | 20 | 52 | 4 |

| HJDK550-035S | 3.5 | 20 | 52 | 4 |

| HJDK550-036S | 3.6 | 20 | 52 | 4 |

| HJDK550-037S | 3.7 | 20 | 52 | 4 |

| HJDK550-038S | 3.8 | 20 | 52 | 4 |

| HJDK550-039S | 3.9 | 22 | 55 | 4 |

| HJDK550-040S | 4 | 22 | 55 | 4 |

| HJDK550-041S | 4.1 | 22 | 55 | 5 |

| HJDK550-042S | 4.2 | 22 | 55 | 5 |

| HJDK550-043S | 4.3 | 22 | 55 | 5 |

| HJDK550-044S | 4.4 | 24 | 55 | 5 |

| HJDK550-045S | 4.5 | 24 | 55 | 5 |

| HJDK550-046S | 4.6 | 24 | 58 | 5 |

| HJDK550-047S | 4.7 | 24 | 58 | 5 |

| HJDK550-048S | 4.8 | 24 | 58 | 5 |

| HJDK550-049S | 4.9 | 26 | 58 | 5 |

| HJDK550 -050S | 5 | 26 | 58 | 5 |

| HJDK550-051S | 5.1 | 26 | 62 | 5.1 |

| HJDK550-052S | 5.2 | 26 | 62 | 5.2 |

| HJDK550-053S | 5.3 | 28 | 62 | 5.3 |

| HJDK550-054S | 5.4 | 28 | 62 | 5.4 |

| HJDK550-055S | 5.5 | 28 | 66 | 5.5 |

| HJDK550-056S | 5.6 | 28 | 66 | 5.6 |

| HJDK550-057S | 5.7 | 28 | 66 | 5.7 |

| HJDK550-058S | 5.8 | 28 | 66 | 5.8 |

| HJDK550-059S | 5.9 | 28 | 66 | 5.9 |

| HJDK550-060S | 6 | 31 | 66 | 6 |

| HJDK550-061S | 6.1 | 31 | 70 | 7 |

| HJDK550-062S | 6.2 | 31 | 70 | 7 |

| HJDK550-063S | 6.3 | 31 | 70 | 7 |

| HJDK550 -064S | 6.4 | 31 | 70 | 7 |

| HJDK550 -065S | 6.5 | 31 | 70 | 7 |

| HJDK550-066S | 6.6 | 31 | 70 | 7 |

| HJDK550-067S | 6.7 | 31 | 70 | 7 |

| HJDK550-068S | 6.8 | 34 | 74 | 7 |

| HJDK550-069S | 6.9 | 34 | 74 | 7 |

| HJDK550-070S | 7 | 34 | 74 | 7 |

| HJDK550-071S | 7.1 | 34 | 74 | 8 |

| HJDK550-072S | 7.2 | 34 | 74 | 8 |

| HJDK550-073S | 7.3 | 34 | 74 | 8 |

| HJDK550-074S | 7.4 | 34 | 74 | 8 |

| HJDK550-075S | 7.5 | 34 | 74 | 8 |

| HJDK550-076S | 7.6 | 37 | 79 | 8 |

| HJDK550-077S | 7.7 | 37 | 79 | 8 |

| HJDK550-078S | 7.8 | 37 | 79 | 8 |

| HJDK550-079S | 7.9 | 37 | 79 | 8 |

| HJDK550-080S | 8 | 37 | 79 | 8 |

| HJDK550-081S | 8.1 | 37 | 79 | 9 |

| HJDK550 -082S | 8.2 | 37 | 79 | 9 |

| HJDK550 -083S | 8.3 | 37 | 79 | 9 |

| HJDK550 -084S | 8.4 | 37 | 79 | 9 |

| HJDK550-085S | 8.5 | 37 | 79 | 9 |

| HJDK550-086S | 8.6 | 40 | 84 | 9 |

| HJDK550-087S | 8.7 | 40 | 84 | 9 |

| HJDK550-088S | 8.8 | 40 | 84 | 9 |

| HJDK550-089S | 8.9 | 40 | 84 | 9 |

| HJDK550-090S | 9 | 40 | 84 | 9 |

| HJDK550-091S | 9.1 | 40 | 84 | 10 |

| HJDK550-092S | 9.2 | 40 | 84 | 10 |

| HJDK550-093S | 9.3 | 40 | 84 | 10 |

| HJDK550-094S | 9.4 | 40 | 84 | 10 |

HJDK550 Carbide Drills

| Kode pesenan | Luar Diaméterna | Suling Panjang | Gemblengna Panjang | Diaméter Shank |

| (D) | (l) | (L) | (D) | |

| HJDK550-095S | 9.5 | 40 | 84 | 10 |

| HJDK550-096S | 9.6 | 43 | 89 | 10 |

| HJDK550-097S | 9.7 | 43 | 89 | 10 |

| HJDK550-098S | 9.8 | 43 | 89 | 10 |

| HJDK550-099S | 9.9 | 43 | 89 | 10 |

| HJDK550-100S | 10 | 43 | 89 | 10 |

| HJDK550-101S | 10.1 | 43 | 89 | 11 |

| HJDK550-102S | 10.2 | 43 | 89 | 11 |

| HJDK550-103S | 10.3 | 43 | 89 | 11 |

| HJDK550-104S | 10.4 | 43 | 89 | 11 |

| HJDK550-105S | 10.5 | 43 | 89 | 11 |

| HJDK550-106S | 10.6 | 43 | 89 | 11 |

| HJDK550-107S | 10.7 | 43 | 89 | 11 |

| HJDK550-108S | 10.8 | 43 | 89 | 11 |

| HJDK550-109S | 10.9 | 43 | 89 | 11 |

| HJDK550-110S | 11 | 47 | 95 | 11 |

| HJDK550-111S | 11.1 | 47 | 95 | 12 |

| HJDK550-112S | 11.2 | 47 | 95 | 12 |

| HJDK550-113S | 11.3 | 47 | 95 | 12 |

| HJDK550-114S | 11.4 | 47 | 95 | 12 |

| HJDK550-115S | 11.5 | 47 | 95 | 12 |

| HJDK550-116S | 11.6 | 47 | 95 | 12 |

| HJDK550-117S | 11.7 | 47 | 95 | 12 |

| HJDK550-118S | 11.8 | 47 | 95 | 12 |

| HJDK550-119S | 11.9 | 47 | 95 | 12 |

| HJDK550-120S | 12 | 51 | 102 | 12 |

| HJDK550-121S | 12.1 | 51 | 102 | 13 |

| HJDK550-122S | 12.2 | 51 | 102 | 13 |

| HJDK550-123S | 12.3 | 51 | 102 | 13 |

| HJDK550-124S | 12.4 | 51 | 102 | 13 |

| HJDK550-125S | 12.5 | 51 | 102 | 13 |

| HJDK550-126S | 12.6 | 51 | 102 | 13 |

| HJDK550-127S | 12.7 | 51 | 102 | 13 |

| HJDK550-128S | 12.8 | 51 | 102 | 13 |

| HJDK550-129S | 12.9 | 51 | 102 | 13 |

| HJDK550-130S | 13 | 51 | 102 | 13 |

HJDK550 Standar Bor:

| Kode pesenan | Luar Diaméterna | Suling Panjang |

| (D) | (l) | |

| HJDK550-0030 | 0.3 | 5.5 |

| HJDK550-0035 | 0.35 | 5.5 |

| HJDK550-0040 | 0.4 | 7 |

| HJDK550-0045 | 0.45 | 7 |

| HJDK550-0050 | 0.5 | 8.5 |

| HJDK550-0055 | 0.55 | 8.5 |

| HJDK550-0060 | 0.6 | 9.5 |

| HJDK550-0065 | 0.65 | 9.5 |

| HJDK550-0070 | 0.7 | 9.5 |

| HJDK550-0075 | 0.75 | 9.5 |

| HJDK550-0080 | 0.8 | 9.5 |

| HJDK550-0085 | 0.85 | 9.5 |

| HJDK550-0090 | 0.9 | 9.5 |

| HJDK550-0095 | 0.95 | 9.5 |

| HJDK550-0100 | 1 | 10.5 |

| HJDK550-0105 | 1.05 | 10.5 |

| HJDK550-0110 | 1.1 | 10.5 |

| HJDK550-0115 | 1.15 | 10.5 |

| HJDK550-0120 | 1.2 | 10.5 |

| HJDK550-0125 | 1.25 | 10.5 |

| HJDK550-0130 | 1.3 | 12 |

| HJDK550-0135 | 1.35 | 12 |

| HJDK550-0140 | 1.4 | 12 |

| HJDK550-0145 | 1.45 | 12 |

| HJDK550-0150 | 1.5 | 12 |

| HJDK550-0155 | 1.55 | 12 |

| HJDK550-0160 | 1.6 | 12 |

| HJDK550-0165 | 1.65 | 12 |

| HJDK550-0170 | 1.7 | 12 |

| HJDK550-0175 | 1.75 | 12 |

| HJDK550-0180 | 1.8 | 12 |

| HJDK550-0185 | 1.85 | 12 |

| HJDK550-0190 | 1.9 | 12 |

| HJDK550-0195 | 1.95 | 12 |

| HJDK550-0200 | 2 | 12 |

| HJDK550-0205 | 2.05 | 12 |

| HJDK550-0210 | 2.1 | 12 |

| HJDK550-0215 | 2.15 | 12 |

| HJDK550-0220 | 2.2 | 12 |

| HJDK550-0225 | 2.25 | 12 |

| HJDK550-0230 | 2.3 | 12 |

| HJDK550-0235 | 2.35 | 12 |

| HJDK550-0240 | 2.4 | 12 |

| HJDK550-0245 | 2.45 | 12 |

| HJDK550-0250 | 2.5 | 12 |

| HJDK550-0255 | 2.55 | 12 |

| HJDK550-0260 | 2.6 | 12 |

| HJDK550-0265 | 2.65 | 12 |

| HJDK550-0270 | 2.7 | 12 |

| HJDK550-0275 | 2.75 | 12 |

| HJDK550-0280 | 2.8 | 12 |

| HJDK550-0285 | 2.85 | 12 |

| HJDK550-0290 | 2.9 | 12 |

| HJDK550-0295 | 2.95 | 12 |

| HJDK550-0300 | 3 | 12 |

| HJDK550-0305 | 3.05 | 12 |

| HJDK550-0310 | 3.1 | 12 |

| HJDK550-0315 | 3.15 | 12 |

| HJDK550-03175 | 3.175 | 12 |

Urang bisa ngahasilkeun 3D, 5D, 8D drills nurutkeun sarat customer urang atawa latihan nonstandard sakumaha ngaropéa. Urang ogé bisa ngahasilkeun pabrik tungtung nonstandard sakumaha ngaropéa.

Komposisi bahan alat:

1.Sipat Fisik:

A) Karasa leuwih gede atawa sarua jeung 92,8 HRA;

B) Kapadetan leuwih gede atawa sarua jeung 14,2 g/cm³;

C) TRS leuwih gede atawa sarua jeung 4200 N/mm²;

D) Bébas tina kaayaan fase ETA;

E) Taya kontaminasi ku bahan séjén;

F) Porositas = A00 / B00 / C00 ;

G) Ukuran sisikian seragam jeung konsisten. Teu aya ukuran butir anu tiasa langkung ageung tibatan anu ditangtukeun.

H) Inhibitor pertumbuhan gandum kromium karbida wungkul.

2.All parabot produksi, coatings dipaké di Jerman, Swiss, alat-alat ngolah;

Lapisan:

Nano palapis AlTiN

Ciri jeung Fungsi

1, eusi aluminium High nyadiakeun karasa panas alus teuing jeung lalawanan oksidasi.

2, métode husus optimizes struktur palapis, nyata ningkat stabilitas, ngurangan jumlah droplet permukaan.

| Parameter operasi bor pendingin éksternal: | |||||||||||

| Bahan workpeice | Laju motong | Laju eupan (mm/rev) | |||||||||

| (m/mnt) | |||||||||||

| Pendinginan éksternal | D3 | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D18 | D20 | |

| bor | |||||||||||

| Baja karbon rendah, chip panjang | 100 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<125HB) | 80 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Baja karbon rendah, potongan pondok, | 100 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| baja gampang dipotong | 75 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<125HB) | 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Baja karbon luhur | 90 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| jeung baja karbon sedang | 70 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<25HRC) | 45 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Baja paduan, baja alat | 90 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<35HRC) | 70 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 45 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Baja paduan, baja alat | 80 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| (35-48HRC) | 60 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| 40 | 0.14 | 0.17 | 0.22 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| PH jeung ferrit, baja martensit | 70 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| (<35HRC) | 50 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| 30 | 0.14 | 0.17 | 0.23 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| Baja tahan karat Austenitik | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.14 | |

| (130-200HB) | 0.08 | 0.1 | 0.12 | 0.13 | 0.15 | 0.17 | 0.18 | 0.2 | 0.22 | 0.24 | |

| 0.1 | 0.12 | 0.14 | 0.18 | 0.2 | 0.22 | 0.24 | 0.24 | 0.26 | 0.28 | ||

| austenit kakuatan luhur | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 | |

| jeung tempa stainless baja | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 | |

| (<25HRC) | 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | |

| Duplex stainless steel | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 | |

| (<30HRC) | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 | |

| 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | ||

| Beusi kulawu | 100 | 0.13 | 0.15 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 |

| (<32HRC) | 80 | 0.17 | 0.02 | 0.26 | 0.32 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | 0.48 |

| 60 | 0.21 | 0.26 | 0.32 | 0.4 | 0.42 | 0.46 | 0.5 | 0.52 | 0.54 | 0.56 | |

| Paduan beusi sedeng | 100 | 0.11 | 0.13 | 0.15 | 0.17 | 0.22 | 0.22 | 0.24 | 0.26 | 0.3 | 0.34 |

| kasusah ngolah, | 80 | 0.15 | 0.18 | 0.23 | 0.26 | 0.28 | 0.34 | 0.35 | 0.4 | 0.4 | 0.43 |

| beusi tuang nodular | 60 | 0.18 | 0.22 | 0.27 | 0.38 | 0.38 | 0.42 | 0.44 | 0.48 | 0.46 | 0.5 |

| (<28HRC) | |||||||||||

| beusi tuang paduan tinggi anu teu tiasa ditarik, | 90 | 0.06 | 0.08 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.23 | 0.23 |

| beusi tuang nodular | 70 | 0.09 | 0.1 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.28 | 0.29 |

| (<28HRC) | 60 | 0.11 | 0.13 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.34 | 0.35 |

| Paduan aluminium tempa | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si<12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Tuang aluminium alloy | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si<12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Tuang aluminium alloy | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si>12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Tambaga, alloy tambaga | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (<200HB) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

Perhatosan:

Pastikeun peice karya jeung mesin anu stabil sarta ngagunakeun wadah precision, make chucks hidrolik, chucks collet kualitas luhur.

Pastikeun total nunjukkeun run-out (TIR) kirang ti 0.02mm.

Kaayaan motong anu disarankeun cocog pikeun nerapkeun cai anu leyur.

Upami ukuran alat henteu aya dina tabél. Mangga tingal pacilingan tabel kana pilihan ukuran diaméterna sabeulah parameter motong, saluyukeun motong parameter nurutkeun kaayaan gawé sabenerna salila ngolah.

Pausahaan ngabogaan sabeulah lengkep garis produksi parabot prosés manufaktur tina bubuk persiapan bahan baku, pembuatan kapang, mencét, tekanan sintering, grinding, palapis jeung palapis pos-perlakuan. Ieu museurkeun kana panalungtikan sarta inovasi tina bahan dasar, struktur alur, precision ngabentuk jeung palapis permukaan carbide NC inserts, sarta terus ngaronjatkeun efisiensi machining, hirup layanan sarta sipat motong séjén tina carbide NC inserts. Saatos langkung ti sapuluh taun panalungtikan ilmiah sareng inovasi, perusahaan parantos ngawasa sababaraha téknologi inti mandiri, gaduh kamampuan R&D sareng desain mandiri, sareng tiasa nyayogikeun produksi khusus pikeun unggal palanggan.