- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

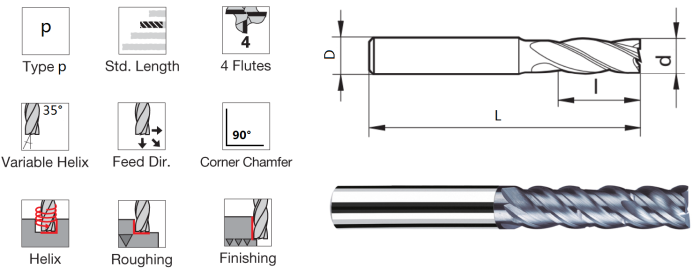

F4 F2 Tungtung Mill pikeun Hardened Steel (48-55 HRC)

Seri HJMJ550 - End Mill pikeun Hardened Steel (48-55 HRC)

HJMJ550 End Mill pikeun Hardened Steels (48-55 HRC)

aplikasi: Pikeun steels hardened (48-55 HRC) pagawean.

Universal High Performance palapis AlCrSiN

F4 F2

Pernyataan literal:

Ngagiling tungtung pikeun paeh loba dipaké, bisa dipasang sarta dipaké dina parabot pneumatic atawa listrik, efisiensi produksi jeung durability ti kabayang grinding sarta nambahan jumlah kali file.

Fitur:

karasa 1.High, bahan matrix kateguhan tinggi, desain sudut husus sarta perlakuan ujung, husus pikeun steels hardened professing.

2.Pikeun hardened steels (48-60 HRC) pagawean.

3.Recommended ngagunakeun hawa atawa minyak halimun cooling.

Ukuran biasa:

1.4 Suling Tungtung Mills

| Luar Diaméterna | Suling Panjang | Gemblengna Panjang | Diaméter Shank | |

| (d) | (l) | (L) | (D) | |

| HJMJ550-4F-D010-L050 | 1.0 | 3.0 | 50 | 4 |

| HJMJ550-4F-D015-L050 | 1.5 | 4.5 | 50 | 4 |

| HJMJ550-4F-D020-L050 | 2.0 | 6.0 | 50 | 4 |

| HJMJ550-4F-D025-L050 | 2.5 | 7.0 | 50 | 4 |

| HJMJ550-4F-D030-L050 | 3.0 | 8.0 | 50 | 4 |

| HJMJ550-4F-D035-L050 | 3.5 | 10.0 | 50 | 4 |

| HJMJ550-4F-D040-L050 | 4.0 | 11.0 | 50 | 4 |

| HJMJ550-4F-D050-L050 | 5.0 | 13.0 | 50 | 6 |

| HJMJ550-4F-D060-L050 | 6.0 | 16.0 | 50 | 6 |

| HJMJ550-4F-D070-L060 | 7.0 | 17.0 | 60 | 8 |

| HJMJ550-4F-D080-L060 | 8.0 | 20.0 | 60 | 8 |

| HJMJ550-4F-D090-L075 | 9.0 | 25.0 | 75 | 10 |

| HJMJ550-4F-D100-L075 | 10.0 | 25.0 | 75 | 10 |

| HJMJ550-4F-D110-L075 | 11.0 | 28.0 | 75 | 12 |

| HJMJ550-4F-D120-L075 | 12.0 | 30.0 | 75 | 12 |

| HJMJ550-4F-D140-L080 | 14.0 | 35.0 | 80 | 14 |

| HJMJ550-4F-D160-L100 | 16.0 | 45.0 | 100 | 16 |

| HJMJ550-4F-D180-L100 | 18.0 | 48.0 | 100 | 18 |

| HJMJ550-4F-D200-L100 | 20.0 | 50.0 | 100 | 20 |

2. 2 Flute Corner Radius End Mills

| Luar Diaméterna | R | Suling Panjang | Gemblengna Panjang | Diaméter Shank | |

| (d) | (l) | (L) | (D) | ||

| HJMJ550-2F-010-02 | 1 | 0.2 | 2 | 50 | 4 |

| HJMJ550-2F-015-02 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ550-2F-015-03 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ550-2F-020-02 | 2 | 0.2 | 4 | 50 | 4 |

| HJMJ550-2F-020-05 | 2 | 0.5 | 4 | 50 | 4 |

| HJMJ550-2F-025-02 | 2.5 | 0.2 | 5 | 50 | 4 |

| HJMJ550-2F-025-05 | 2.5 | 0.5 | 5 | 50 | 4 |

| HJMJ550-2F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ550-2F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ550-2F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ550-2F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ550-2F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ550-2F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ550-2F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ550-2F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ550-2F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ550-2F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ550-2F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ550-2F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ550-2F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ550-2F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ550-2F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ550-2F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ550-2F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ550-2F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ550-2F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ550-2F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ550-2F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ550-2F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ550-2F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ550-2F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ550-2F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ550-2F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ550-2F-120-20 | 12 | 20 | 24 | 75 | 12 |

| HJMJ550-2F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ550-2F-120-30 | 12 | 3 | 24 | 75 | 12 |

3.4 Suling Corner Radius tungtung Mills

| Luar Diaméterna | R | Suling Panjang | Gemblengna Panjang | Diaméter Shank | |

| (d) | (l) | (L) | (D) | ||

| HJMJ550-4F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ550-4F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ550-4F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ550-4F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ550-4F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ550-4F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ550-4F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ550-4F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ550-4F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ550-4F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ550-4F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ550-4F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ550-4F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ550-4F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ550-4F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ550-4F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ550-4F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ550-4F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ550-4F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ550-4F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ550-4F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ550-4F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ550-4F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ550-4F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ550-4F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ550-4F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ550-4F-120-20 | 12 | 2 | 24 | 75 | 12 |

| HJMJ550-4F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ550-4F-120-30 | 12 | 3 | 24 | 75 | 12 |

Komposisi bahan alat

Universal High Performance palapis AlCrSiN

Ciri jeung Fungsi

1, kanaékan produktivitas alatan speed motong nyata luhur sarta feed pikeun aplikasi dina rupa-rupa materials.Significantly ditingkatkeun produktivitas.

2, Desain husus tina struktur brings kasaimbangan alus antara kateguhan, stabilitas thermo-shock jeung stress residual.

Parameter operasi:

| HJMJ550 End mill for die Operation parameter: | |||||||||||||

| HJMJ550-S2 For Alloy Steel,Hardened Steel-Side Milling | |||||||||||||

| Sasmita | Bentuk alat | Bahan Benda Kerja | jerona motong (mm) | VC | Diaméter alat | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| S2 | m / mnt | (mm) | |||||||||||

| HJMJ550 | Persegi, sudut radius | Paduan baja dipaénkeun baja | ap≤1D | 120 | Laju | 19100 | 9550 | 6730 | 4780 | 3820 | 3190 | 2390 | 1910 |

| HRC55 | (min-1) | ||||||||||||

| ae≤0.05D | Laju eupan | 380 | 380 | 380 | 380 | 370 | 360 | 310 | 290 | ||||

| (mm/mnt) | |||||||||||||

Perhatosan:

Pastikeun sapotong karya jeung mesin anu stabil sarta ngagunakeun wadah precision.

Mangga saluyukeun speed, feed jeung motong jero nurutkeun kaayaan motong sabenerna.

Conditiongs panggilingan pikeun hiji ngagiling tungtung dimana alat overhang panjangna kirang ti 4 * D (ngagiling dia). Nalika alat overhang panjangna leuwih panjang, mangga saluyukeun speed, feed jeung motong jero.

Pausahaan ngabogaan sabeulah lengkep garis produksi parabot prosés manufaktur tina bubuk persiapan bahan baku, pembuatan kapang, mencét, tekanan sintering, grinding, palapis jeung palapis pos-perlakuan. Ieu museurkeun kana panalungtikan sarta inovasi tina bahan dasar, struktur alur, precision ngabentuk jeung palapis permukaan carbide NC inserts, sarta terus ngaronjatkeun efisiensi machining, hirup layanan sarta sipat motong séjén tina carbide NC inserts. Saatos langkung ti sapuluh taun panalungtikan ilmiah sareng inovasi, perusahaan parantos ngawasa sababaraha téknologi inti mandiri, gaduh kamampuan R&D sareng desain mandiri, sareng tiasa nyayogikeun produksi khusus pikeun unggal palanggan.