- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

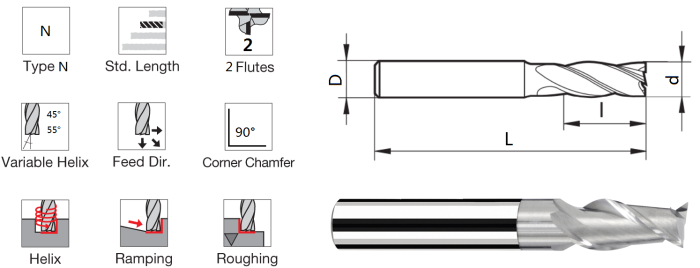

F2 F3 End leloala bakeng sa machining a lebelo le phahameng a aerospace alloys aluminium

Bakeng sa Aerospace Aluminium Alloy

HJA650 Qetellong ea leloala Bakeng sa Aerospace Aluminium Alloy

E loketse bakeng sa machining a lebelo le phahameng la li-alloys tsa aluminium tsa aerospace

Carbide e entsoeng ka samente e ntle haholo, e phahameng ea ho hanyetsa le ho tiea

F2 F3

Tlhaloso ea sebele:

Moralo oa liphala tse tharo oa Aero-Tech o ntlafalitsoe bakeng sa ho etsa metjhini e baballang chelete e ngata ea litšepe tse akaretsang, tšepe e sa hloekang, litšepe tse nang le motsoako o phahameng hammoho le lialloi tsa titanium le nickel. Lisebelisoa tsohle tsa ho qetela tsa Aero-Tech li na le tšireletso e nyane ea sekhutlo bakeng sa bophelo bo atolositsoeng ba lisebelisoa. E fumaneha ka liaparo tse koetsoeng kapa tse khanyang tse phethiloeng joalo ka litekanyetso tse bolokiloeng.

Sebopeho:

E loketse bakeng sa machining a lebelo le phahameng la li-alloys tsa aluminium tsa aerospace

Carbide e entsoeng ka samente e ntle haholo, e phahameng ea ho hanyetsa le ho tiea.

Moralo o khethehileng oa symmetry le ho nepahala ka ho leka-lekana N=25000RPM, G2.0 e ntle bakeng sa ho itšeha ka lebelo le phahameng.

HJA650 e na le masoba a ka hare a pholileng a fanang ka ts'ebetso ea ho pholisa e sebetsang haholoanyane ka sebaka sa ho itšeha bakeng sa machining a lebelo le phahameng.

Mehato e ikhethang e hlabang e fana ka ts'ebetso e eketsehileng ka boreleli le ho phethela.

E sebetsa hantle haholo ho siloa ha cavity ka tšepe e tlosang lebelo ho fihla ho 800cc/min.

Boholo bo tloaelehileng:

1. Ultrafine likaroloana tsa2 phala aluminium ea ho qetela

| Ho odara khouto | Diameter | Bolelele ba Flute | O.A.L. | Shank Dia. |

| HJA650-0302 | 3 | 9.0 | 50 | 3 |

| HJA650-0102 | 1 | 4.0 | 50 | 4 |

| HJA650-0152 | 1.5 | 5.0 | 50 | 4 |

| HJA650-0202 | 2 | 6.0 | 50 | 4 |

| HJA650-0252 | 2.5 | 7.0 | 50 | 4 |

| HJA650-0302 | 3 | 9.0 | 50 | 4 |

| HJA650-0352 | 3.5 | 10.0 | 50 | 4 |

| HJA650-0402 | 4 | 12.0 | 50 | 4 |

| HJA650-0502 | 5 | 15.0 | 50 | 5 |

| HJA650-0102 | 1 | 4.0 | 50 | 6 |

| HJA650-0152 | 1.5 | 5.0 | 50 | 6 |

| HJA650-0202 | 2 | 6.0 | 50 | 6 |

| HJA650-0302 | 3 | 9.0 | 50 | 6 |

| HJA650-0402 | 4 | 12.0 | 50 | 6 |

| HJA650-0502 | 5 | 15.0 | 50 | 6 |

| HJA650-0620 | 6 | 18.0 | 50 | 6 |

| HJA650-0802 | 8 | 20.0 | 60 | 8 |

| HJA650-1002 | 10 | 30.0 | 75 | 10 |

| HJA650-1202 | 12 | 30.0 | 75 | 12 |

2.Ultrafine particles tsa 3 flute aluminium End mill

| Ho odara khouto | Diameter | Bolelele ba Flute | O.A.L. | Shank Dia. |

| HJA650-0303 | 3 | 9 | 50 | 3 |

| HJA650-0103 | 1 | 4 | 50 | 4 |

| HJA650-0153 | 1.5 | 5 | 50 | 4 |

| HJA650-0203 | 2 | 6.0 | 50 | 4 |

| HJA650-0253 | 2.5 | 7 | 50 | 4 |

| HJA650-0303 | 3 | 9 | 50 | 4 |

| HJA650-0353 | 3.5 | 10.0 | 50 | 4 |

| HJA650-0403 | 4 | 12 | 50 | 4 |

| HJA650-0503 | 5 | 15 | 50 | 5 |

| HJA650-0103 | 1 | 4 | 50 | 6 |

| HJA650-0153 | 1.5 | 5 | 50 | 6 |

| HJA650-0203 | 2 | 6 | 50 | 6 |

| HJA650-0253 | 2.5 | 7 | 50 | 6 |

| HJA650-0303 | 3 | 9 | 50 | 6 |

| HJA650-0403 | 4 | 12 | 50 | 6 |

| HJA650-0503 | 5 | 15 | 50 | 6 |

| HJA650-0603 | 6 | 18 | 50 | 6 |

| HJA650-0803 | 8 | 20 | 60 | 8 |

| HJA650-1003 | 10 | 30 | 75 | 10 |

| HJA650-1203 | 12 | 30 | 75 | 12 |

Sebopeho sa lisebelisoa:

1. Thepa ea 'Mele:

A) Bothata bo boholo ho feta kapa bo lekana le 94 HRA;

B) Botenya bo boholo ho feta kapa bo lekana le 14.6g/cm³;

C) TRS e kholo ho feta kapa e lekana le 4100 N/mm²;

2. Lisebelisoa tsohle tsa tlhahiso, liphahlo li sebelisoa Jeremane, Switzerland, lisebelisoa tsa ho sebetsa;

Tšebetso parameter:

| HJA650 operation parameter of end mill for aerospace aluminum alloy:HJA650-RN2 | |||||||||

| HJA650 RN2 For Aerospace Aluminium Alloy-Side Milling | |||||||||

| Kereiti | Sebopeho sa sesebelisoa | Workpiece Material | Ho teba | VC | Tool Diameter | 10 | 12 | 16 | 20 |

| RN2 | (mm) | m/m | (mm) | ||||||

| HJA650 | Aluminium alloy 7075,7050 (Si<6%) | ap≤0.25D | 400 | lebelo | 12000 | 10000 | 8000 | 7000 | |

| (300-500) | (min-1) | ||||||||

| ae≤0.5 | sekhahla phepelo | 3600 | 3300 | 3200 | 3080 | ||||

| (mm/mots) | |||||||||

Tlhokomeliso:

Etsa bonnete ba hore karolo ea mosebetsi le mochini li tsitsitse 'me li sebelisa sets'oants'o se nepahetseng.

Ka kopo, lokisa lebelo, phepelo le botebo ba ho itšeha ho latela maemo a 'nete a ho itšeha.

Li-conditiongs tsa ho sila ke tsa leloala la ho qetela moo bolelele ba sesebelisoa bo fetang 4*D(mill dia). Ha bolelele ba sesebelisoa bo le telele, ka kopo fetola lebelo, fepa le botebo ba ho itšeha.

Khamphani e na le mohala o felletseng oa tlhahiso ea lisebelisoa tsa lehare ho tloha ho tokiso ea lihlahisoa tse tala, ho etsa hlobo, ho hatella, ho sila ka khatello, ho sila, ho roala le ho roala ka mor'a kalafo. E shebane le lipatlisiso le boqapi ba lisebelisoa tsa motheo, sebopeho sa groove, ho etsoa ka nepo le ho roala ka holim'a li-carbide NC, 'me e lula e ntlafatsa ts'ebetso ea machining, bophelo ba ts'ebeletso le lisebelisoa tse ling tsa ho itšeha tsa carbide NC inserts. Ka mor'a lilemo tse fetang leshome tsa lipatlisiso tsa saense le mekhoa e mecha, k'hamphani e tseba mekhoa e mengata ea motheo e ikemetseng, e na le R&D e ikemetseng le bokhoni ba ho qapa, 'me e ka fana ka tlhahiso e ikhethileng bakeng sa moreki e mong le e mong.