- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

HJDK650 Tungsten carbide toleniga tutotonu

Tungsten carbide toleniga tutotonu

HJDK650 Tungsten carbide toleniga tutotonu

E fetaui mo le viliina o u'amea, u'amea u'amea, u'amea lafo, mea e le-ferrous.

Malosi HRA92.8

Mea: tungsten carbide

HJDK650 fa'asologa-totonu toleniga

Fa'amatalaga moni:

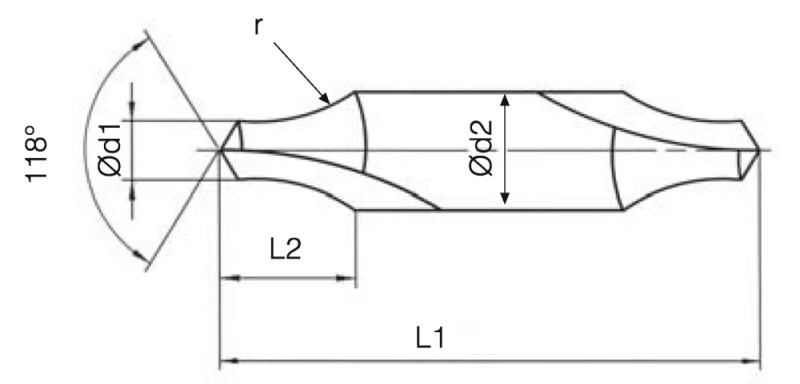

HJDK650 vili ogatotonu e iloa ai se tu'ufa'atasiga lelei i le va o le tafega i le vaega vili ma le vaega fa'atau. O a latou fagufagu e mafai ona ofi atoa ai tupe meataalo ma galue lelei e fa'ate'a ese le chips.center drills o lo'o i ai pito tipi i pito uma e lua, ma e iai ni fagufagu. malosi, ua tatou faaitiitia le umi vili. E toe fa'amalieina le vaivai i le nofoaga feso'ota'i i le va o le vili ma le fa'amau, o le pito feso'ota'i o lo'o iai le R lea o lo'o i totonu o le pito i tua o le vili. E i ai foi a latou laina lautele.

Vaega:

E fetaui mo le viliina o u'amea, u'amea u'amea, u'amea lafo, mea e le-ferrous.

Fa'a fa'a'au'au, lelei le fa'atotonugalemu.

Mata'itusi, la'ititi la'ititi o le tipi.

Laugutu laugutu, maualuga le fua fafaga, sili atu le lelei.

Tele masani:HJDK650 Fine Powder Center Drill Series

| Fa'atonu code | Diamita | Angle | Umi faaili | O.A.L. | Shank Dia. |

| HJDK650-0102 | 1 | 60° | 1.5 | 35 | 4 |

| HJDK650-0202 | 2 | 60° | 2.5 | 50 | 5 |

| HJDK650-0252 | 2.5 | 60° | 3 1 | 60 | 6.3 |

| HJDK650-03152 | 3.15 | 60° | 3.9 | 70 | 8 |

| HJDK650-0402 | 4 | 60° | 5 | 80 | 10 |

| HJDK650-0502 | 5 | 60° | 6.3 | 80 | 12 |

| HJDK650-0632 | 6.3 | 60° | 80 | 80 | 16 |

Mea faigaluega tu'ufa'atasiga:

1. Meatotino Faaletino:

A) Maaa sili atu pe tutusa ma le 92.8 HRA;

B) Ole mamafa e sili atu pe tutusa ile 14.2 g/cm³;

C) TRS sili atu pe tutusa ile 4200 N/mm²;

D) Sa'oloto mai le tulaga vaega ETA;

E) Leai se fa'aleagaina e isi mea;

F) Porosity = A00 / B00 / C00 ;

G) Tulaga tutusa ma tutusa le lapopoa o fatu. E leai se lapo'a fatu e mafai ona lapopoa nai lo le mea ua fa'ailoa mai.

H) Na'o le fa'atosina o le tuputupu a'e o saito Chromium carbide.

2. O meafaigaluega uma o le gaosiga, faʻapipiʻi e faʻaaogaina i Siamani, Suiselani, meafaigaluega faʻagaioia;

Fa'atino parata:

| Fa'ata'otoga liina Gaoga : | ||||||||||

| Meafaitino mea faigaluega | Saosaoa le tipi | Fuafuaga fafaga (mm/rev) | ||||||||

| (m/min) | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D20 | ||

| Low carbon steel, long chip (<125HB) | 130 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.15 | 0.17 | 0.2 | 0.24 | 0.26 | 0.3 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.26 | 0.3 | 0.32 | 0.35 | 0.4 | 0.45 | ||

| u'amea maualalo, 'oti pu'upu'u, u'amea faigofie ( | 120 | 0.1 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.24 | 0.3 | 0.32 | 0.34 | 0.4 | 0.45 | ||

| Uamea maualuga kaponi ma umea umea umea ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Uamea uamea, uamea meafaigaluega ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| u'amea u'amea, u'amea meafaigaluega (35-48HRC) | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| PH ma ferritic, martensitic umea ( | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Gray iron(<32HRC) | 140 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| u'amea u'amea ole fa'agaioiga fa'aletonu, u'amea u'amea u'amea ( | 130 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 105 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| u'amea fa'a'u'u maualuga e mafai ona fa'aogaina, u'amea u'amea ( | 120 | 0.1 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.28 | |

| 90 | 0.16 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.29 | ||

| 60 | 0.22 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.35 | ||

| u'amea alumini (Si | 150 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Fa'a'a'umi alumini (Si | 150 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 120 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Fa'a'amea alumini (Si>12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| 12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

Kopa, apamemea (

Fa'alogo:

Ia mautinoa o mea faigaluega ma masini e mautu ma faʻaaoga se mea e teu ai, faʻaaoga puʻu eletise, faʻamalo maualuga.

Ia mautinoa o le aofa'i o fa'ai'uga fa'ailoa (TIR) e itiiti ifo i le 0.02mm.

O le tulaga fa'atonuina o le tipi e talafeagai mo le fa'aogaina o le vai soluable.

O loʻo i ai i le kamupani se laʻau atoa gaosiga o meafaigaluega gaosiga laina mai le paʻu o mea mataʻu sauniuniga, faʻapipiʻi, oomiina, sintering mamafa, olo, faʻapipiʻi ma faʻapipiʻi pe a maeʻa togafitiga. O loʻo taulaʻi i le suʻesuʻega ma le faʻafouina o mea faʻavae, fausaga faʻapipiʻi, faʻapipiʻi saʻo ma le faʻapipiʻiina o luga ole carbide NC faʻapipiʻi, ma faʻaleleia pea le faʻaogaina o masini, ola tautua ma isi mea tipiina o faʻapipiʻi NC carbide. A maeʻa le sili atu ma le sefulu tausaga o suʻesuʻega faʻasaienisi ma faʻafouga, ua faʻatautaia e le kamupani le tele o tekinolosi faʻapitoa tutoʻatasi, ei ai le R & D tutoʻatasi ma le gafatia o mamanu, ma e mafai ona tuʻuina atu faʻasalalauga faʻapitoa mo tagata faʻatau taʻitasi.