- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

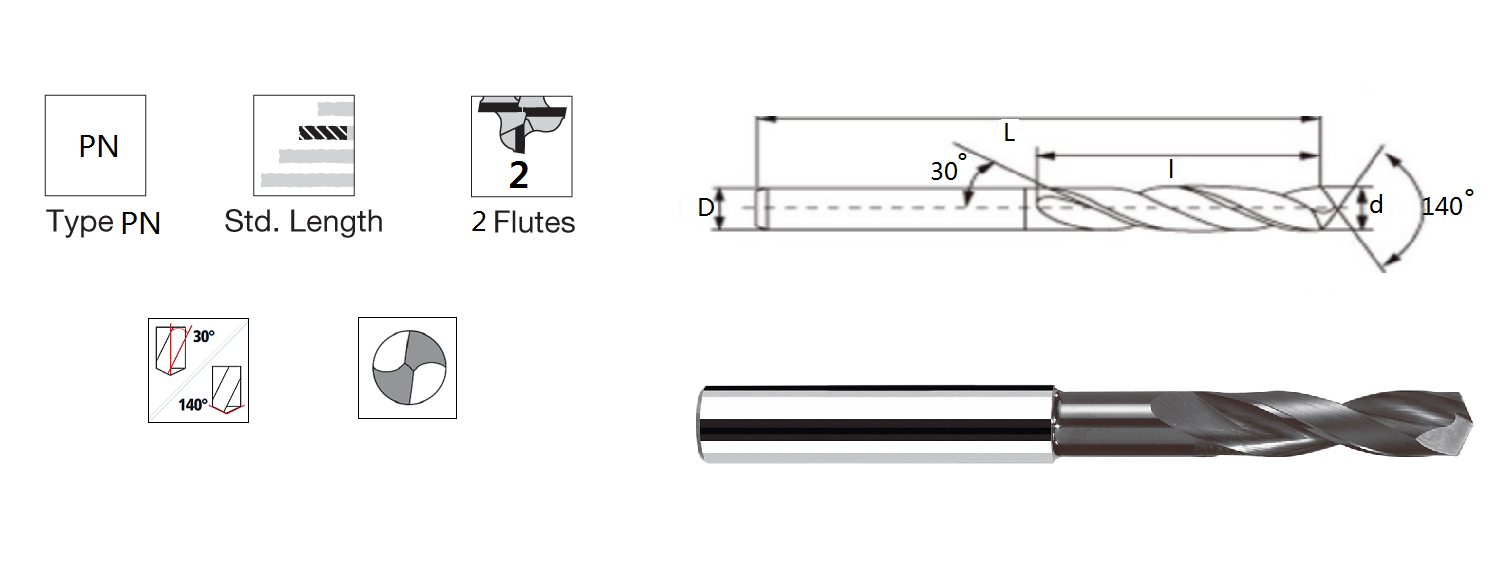

Tungsten carbide Bor cooling njaba

Bor cooling njaba

HJDK550 seri-pengeboran cooling njaba

Cocog kanggo pengeboran baja, stainless steel, wesi cor, bahan non-ferrous.

Nano Coating AlTiN

Bahan: tungsten karbida

Pernyataan harfiah:

Drill HJDK550 dikembangake kanggo mesin kompleks bahan baja. Iku ndadekake roso kesengsem kuwat karo dhuwur nglereni nilai lan terus-terusan kualitas bolongan apik. Pinggiran pemotongan sing stabil lan akurat diprodhuksi amarga geometri mikro khusus. Rampung lumahing banget Gamelan saka web thinning lan profil suling nyuda gesekan antarane pengeboran lan chip. Suhu mesin suda lan evakuasi chip apik. Motong pasukan suda. Fitur alat kasebut ngasilake kualitas bolongan maksimal lan umur alat.

Fitur:

Cocog kanggo pengeboran baja, stainless steel, wesi cor, bahan non-ferrous.

Pahat rintisan, kemampuan pusat diri sing apik banget.

Titik radial, resistensi pemotongan sing luwih cilik.

Lip chamfer, tingkat feed sing luwih dhuwur, efisiensi sing luwih dhuwur.

Ukuran biasa:

Bor karbida

| Kode pesenan | Diameter njaba | Suling Panjang | Sakabèhé dawa | Diameter Shank |

| (D) | (l) | (L) | (D) | |

| HJDK550-005S | 0.5 | 6 | 26 | 0.5 |

| HJDK550-006S | 0.6 | 6 | 26 | 0.6 |

| HJDK550-007S | 0.7 | 6 | 26 | 0.7 |

| HJDK550-008S | 0.8 | 6 | 26 | 0.8 |

| HJDK550-009S | 0.9 | 6 | 26 | 0.9 |

| HJDK550-0100S | 1 | 6 | 26 | 1 |

| HJDK550-011S | 1.1 | 7 | 28 | 1.1 |

| HJDK550-012S | 1.2 | 8 | 30 | 1.2 |

| HJDK550-013S | 1.3 | 8 | 30 | 1.3 |

| HJDK550-014S | 1.4 | 9 | 32 | 1.4 |

| HJDK550-015S | 1.5 | 9 | 32 | 1.5 |

| HJDK550-016S | 1.6 | 10 | 34 | 1.6 |

| HJDK550-017S | 1.7 | 10 | 34 | 1.7 |

| HJDK550-018S | 1.8 | 11 | 36 | 1.8 |

| HJDK550-019S | 1.9 | 11 | 36 | 1.9 |

| HJDK550-020S | 2 | 12 | 38 | 2 |

| HJDK550-021S | 2.1 | 12 | 38 | 3 |

| HJDK550-022S | 2.2 | 13 | 40 | 3 |

| HJDK550-023S | 2.3 | 13 | 40 | 3 |

| HJDK550-024S | 2.4 | 14 | 43 | 3 |

| HJDK550-025S | 2.5 | 14 | 43 | 3 |

| HJDK550-026S | 2.6 | 14 | 43 | 3 |

| HJDK550-027S | 2.7 | 16 | 46 | 3 |

| HJDK550-028S | 2.8 | 16 | 46 | 3 |

| HJDK550-029S | 2.9 | 16 | 46 | 3 |

| HJDK550-030S | 3 | 16 | 46 | 3 |

| HJDK550-031S | 3.1 | 18 | 49 | 4 |

| HJDK550-032S | 3.2 | 18 | 49 | 4 |

| HJDK550-033S | 3.3 | 18 | 49 | 4 |

| HJDK550-034S | 3.4 | 20 | 52 | 4 |

| HJDK550-035S | 3.5 | 20 | 52 | 4 |

| HJDK550-036S | 3.6 | 20 | 52 | 4 |

| HJDK550-037S | 3.7 | 20 | 52 | 4 |

| HJDK550-038S | 3.8 | 20 | 52 | 4 |

| HJDK550-039S | 3.9 | 22 | 55 | 4 |

| HJDK550-040S | 4 | 22 | 55 | 4 |

| HJDK550-041S | 4.1 | 22 | 55 | 5 |

| HJDK550-042S | 4.2 | 22 | 55 | 5 |

| HJDK550-043S | 4.3 | 22 | 55 | 5 |

| HJDK550-044S | 4.4 | 24 | 55 | 5 |

| HJDK550-045S | 4.5 | 24 | 55 | 5 |

| HJDK550-046S | 4.6 | 24 | 58 | 5 |

| HJDK550-047S | 4.7 | 24 | 58 | 5 |

| HJDK550-048S | 4.8 | 24 | 58 | 5 |

| HJDK550-049S | 4.9 | 26 | 58 | 5 |

| HJDK550 -050S | 5 | 26 | 58 | 5 |

| HJDK550-051S | 5.1 | 26 | 62 | 5.1 |

| HJDK550-052S | 5.2 | 26 | 62 | 5.2 |

| HJDK550-053S | 5.3 | 28 | 62 | 5.3 |

| HJDK550-054S | 5.4 | 28 | 62 | 5.4 |

| HJDK550-055S | 5.5 | 28 | 66 | 5.5 |

| HJDK550-056S | 5.6 | 28 | 66 | 5.6 |

| HJDK550-057S | 5.7 | 28 | 66 | 5.7 |

| HJDK550-058S | 5.8 | 28 | 66 | 5.8 |

| HJDK550-059S | 5.9 | 28 | 66 | 5.9 |

| HJDK550-060S | 6 | 31 | 66 | 6 |

| HJDK550-061S | 6.1 | 31 | 70 | 7 |

| HJDK550-062S | 6.2 | 31 | 70 | 7 |

| HJDK550-063S | 6.3 | 31 | 70 | 7 |

| HJDK550 -064S | 6.4 | 31 | 70 | 7 |

| HJDK550 -065S | 6.5 | 31 | 70 | 7 |

| HJDK550-066S | 6.6 | 31 | 70 | 7 |

| HJDK550-067S | 6.7 | 31 | 70 | 7 |

| HJDK550-068S | 6.8 | 34 | 74 | 7 |

| HJDK550-069S | 6.9 | 34 | 74 | 7 |

| HJDK550-070S | 7 | 34 | 74 | 7 |

| HJDK550-071S | 7.1 | 34 | 74 | 8 |

| HJDK550-072S | 7.2 | 34 | 74 | 8 |

| HJDK550-073S | 7.3 | 34 | 74 | 8 |

| HJDK550-074S | 7.4 | 34 | 74 | 8 |

| HJDK550-075S | 7.5 | 34 | 74 | 8 |

| HJDK550-076S | 7.6 | 37 | 79 | 8 |

| HJDK550-077S | 7.7 | 37 | 79 | 8 |

| HJDK550-078S | 7.8 | 37 | 79 | 8 |

| HJDK550-079S | 7.9 | 37 | 79 | 8 |

| HJDK550-080S | 8 | 37 | 79 | 8 |

| HJDK550-081S | 8.1 | 37 | 79 | 9 |

| HJDK550 -082S | 8.2 | 37 | 79 | 9 |

| HJDK550 -083S | 8.3 | 37 | 79 | 9 |

| HJDK550 -084S | 8.4 | 37 | 79 | 9 |

| HJDK550-085S | 8.5 | 37 | 79 | 9 |

| HJDK550-086S | 8.6 | 40 | 84 | 9 |

| HJDK550-087S | 8.7 | 40 | 84 | 9 |

| HJDK550-088S | 8.8 | 40 | 84 | 9 |

| HJDK550-089S | 8.9 | 40 | 84 | 9 |

| HJDK550-090S | 9 | 40 | 84 | 9 |

| HJDK550-091S | 9.1 | 40 | 84 | 10 |

| HJDK550-092S | 9.2 | 40 | 84 | 10 |

| HJDK550-093S | 9.3 | 40 | 84 | 10 |

| HJDK550-094S | 9.4 | 40 | 84 | 10 |

Pengeboran Karbida HJDK550

| Kode pesenan | Diameter njaba | Suling Panjang | Sakabèhé dawa | Diameter Shank |

| (D) | (l) | (L) | (D) | |

| HJDK550-095S | 9.5 | 40 | 84 | 10 |

| HJDK550-096S | 9.6 | 43 | 89 | 10 |

| HJDK550-097S | 9.7 | 43 | 89 | 10 |

| HJDK550-098S | 9.8 | 43 | 89 | 10 |

| HJDK550-099S | 9.9 | 43 | 89 | 10 |

| HJDK550-100S | 10 | 43 | 89 | 10 |

| HJDK550-101S | 10.1 | 43 | 89 | 11 |

| HJDK550-102S | 10.2 | 43 | 89 | 11 |

| HJDK550-103S | 10.3 | 43 | 89 | 11 |

| HJDK550-104S | 10.4 | 43 | 89 | 11 |

| HJDK550-105S | 10.5 | 43 | 89 | 11 |

| HJDK550-106S | 10.6 | 43 | 89 | 11 |

| HJDK550-107S | 10.7 | 43 | 89 | 11 |

| HJDK550-108S | 10.8 | 43 | 89 | 11 |

| HJDK550-109S | 10.9 | 43 | 89 | 11 |

| HJDK550-110S | 11 | 47 | 95 | 11 |

| HJDK550-111S | 11.1 | 47 | 95 | 12 |

| HJDK550-112S | 11.2 | 47 | 95 | 12 |

| HJDK550-113S | 11.3 | 47 | 95 | 12 |

| HJDK550-114S | 11.4 | 47 | 95 | 12 |

| HJDK550-115S | 11.5 | 47 | 95 | 12 |

| HJDK550-116S | 11.6 | 47 | 95 | 12 |

| HJDK550-117S | 11.7 | 47 | 95 | 12 |

| HJDK550-118S | 11.8 | 47 | 95 | 12 |

| HJDK550-119S | 11.9 | 47 | 95 | 12 |

| HJDK550-120S | 12 | 51 | 102 | 12 |

| HJDK550-121S | 12.1 | 51 | 102 | 13 |

| HJDK550-122S | 12.2 | 51 | 102 | 13 |

| HJDK550-123S | 12.3 | 51 | 102 | 13 |

| HJDK550-124S | 12.4 | 51 | 102 | 13 |

| HJDK550-125S | 12.5 | 51 | 102 | 13 |

| HJDK550-126S | 12.6 | 51 | 102 | 13 |

| HJDK550-127S | 12.7 | 51 | 102 | 13 |

| HJDK550-128S | 12.8 | 51 | 102 | 13 |

| HJDK550-129S | 12.9 | 51 | 102 | 13 |

| HJDK550-130S | 13 | 51 | 102 | 13 |

Bor HJDK550 Standar:

| Kode pesenan | Diameter njaba | Suling Panjang |

| (D) | (l) | |

| HJDK550-0030 | 0.3 | 5.5 |

| HJDK550-0035 | 0.35 | 5.5 |

| HJDK550-0040 | 0.4 | 7 |

| HJDK550-0045 | 0.45 | 7 |

| HJDK550-0050 | 0.5 | 8.5 |

| HJDK550-0055 | 0.55 | 8.5 |

| HJDK550-0060 | 0.6 | 9.5 |

| HJDK550-0065 | 0.65 | 9.5 |

| HJDK550-0070 | 0.7 | 9.5 |

| HJDK550-0075 | 0.75 | 9.5 |

| HJDK550-0080 | 0.8 | 9.5 |

| HJDK550-0085 | 0.85 | 9.5 |

| HJDK550-0090 | 0.9 | 9.5 |

| HJDK550-0095 | 0.95 | 9.5 |

| HJDK550-0100 | 1 | 10.5 |

| HJDK550-0105 | 1.05 | 10.5 |

| HJDK550-0110 | 1.1 | 10.5 |

| HJDK550-0115 | 1.15 | 10.5 |

| HJDK550-0120 | 1.2 | 10.5 |

| HJDK550-0125 | 1.25 | 10.5 |

| HJDK550-0130 | 1.3 | 12 |

| HJDK550-0135 | 1.35 | 12 |

| HJDK550-0140 | 1.4 | 12 |

| HJDK550-0145 | 1.45 | 12 |

| HJDK550-0150 | 1.5 | 12 |

| HJDK550-0155 | 1.55 | 12 |

| HJDK550-0160 | 1.6 | 12 |

| HJDK550-0165 | 1.65 | 12 |

| HJDK550-0170 | 1.7 | 12 |

| HJDK550-0175 | 1.75 | 12 |

| HJDK550-0180 | 1.8 | 12 |

| HJDK550-0185 | 1.85 | 12 |

| HJDK550-0190 | 1.9 | 12 |

| HJDK550-0195 | 1.95 | 12 |

| HJDK550-0200 | 2 | 12 |

| HJDK550-0205 | 2.05 | 12 |

| HJDK550-0210 | 2.1 | 12 |

| HJDK550-0215 | 2.15 | 12 |

| HJDK550-0220 | 2.2 | 12 |

| HJDK550-0225 | 2.25 | 12 |

| HJDK550-0230 | 2.3 | 12 |

| HJDK550-0235 | 2.35 | 12 |

| HJDK550-0240 | 2.4 | 12 |

| HJDK550-0245 | 2.45 | 12 |

| HJDK550-0250 | 2.5 | 12 |

| HJDK550-0255 | 2.55 | 12 |

| HJDK550-0260 | 2.6 | 12 |

| HJDK550-0265 | 2.65 | 12 |

| HJDK550-0270 | 2.7 | 12 |

| HJDK550-0275 | 2.75 | 12 |

| HJDK550-0280 | 2.8 | 12 |

| HJDK550-0285 | 2.85 | 12 |

| HJDK550-0290 | 2.9 | 12 |

| HJDK550-0295 | 2.95 | 12 |

| HJDK550-0300 | 3 | 12 |

| HJDK550-0305 | 3.05 | 12 |

| HJDK550-0310 | 3.1 | 12 |

| HJDK550-0315 | 3.15 | 12 |

| HJDK550-03175 | 3.175 | 12 |

Kita bisa ngasilake latihan 3D, 5D, 8D miturut syarat pelanggan utawa latihan sing ora standar minangka disesuaikan. Kita uga bisa gawé pabrik pungkasan nonstandard minangka selaras.

Komposisi bahan alat:

1. Sifat Fisik:

A) Kekerasan luwih saka utawa padha karo 92,8 HRA;

B) Kapadhetan luwih saka utawa padha karo 14,2 g/cm³;

C) TRS luwih saka utawa padha karo 4200 N/mm²;

D) Bebas saka kondisi fase ETA;

E) Ora ana kontaminasi dening bahan liyane;

F) Porositas = A00 / B00 / C00 ;

G) Ukuran gandum seragam lan konsisten. Ora ana ukuran gandum sing bisa luwih gedhe tinimbang sing ditemtokake.

H) Inhibitor pertumbuhan biji kromium karbida mung.

2. Kabeh alat produksi, lapisan digunakake ing Jerman, Swiss, peralatan pangolahan;

Lapisan:

Nano Coating AlTiN

Karakteristik lan Fungsi

1, isi aluminium dhuwur menehi atose panas banget lan resistance oksidasi.

2. Cara khusus ngoptimalake struktur lapisan, stabilitas sing luwih apik, nyuda jumlah tetesan permukaan.

| Parameter operasi bor pendingin eksternal: | |||||||||||

| Bahan workpeice | Kacepetan ngethok | Tingkat feed (mm/rev) | |||||||||

| (m/min) | |||||||||||

| Pendinginan eksternal | D3 | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D18 | D20 | |

| pengeboran | |||||||||||

| Baja karbon rendah, chip dawa | 100 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<125HB) | 80 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Baja karbon rendah, potong cendhak, | 100 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| baja sing gampang dipotong | 75 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<125HB) | 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Baja karbon dhuwur | 90 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| lan baja karbon menengah | 70 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<25HRC) | 45 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Baja paduan, baja alat | 90 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<35HRC) | 70 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 45 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Baja paduan, baja perkakas | 80 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| (35-48HRC) | 60 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| 40 | 0.14 | 0.17 | 0.22 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| PH lan feritik, baja martensit | 70 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| (<35HRC) | 50 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| 30 | 0.14 | 0.17 | 0.23 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| Baja tahan karat Austenitik | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.14 | |

| (130-200HB) | 0.08 | 0.1 | 0.12 | 0.13 | 0.15 | 0.17 | 0.18 | 0.2 | 0.22 | 0.24 | |

| 0.1 | 0.12 | 0.14 | 0.18 | 0.2 | 0.22 | 0.24 | 0.24 | 0.26 | 0.28 | ||

| Austenitic kekuatan dhuwur | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 | |

| lan tempa stainless baja | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 | |

| (<25HRC) | 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | |

| Duplex stainless steel | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 | |

| (<30HRC) | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 | |

| 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | ||

| Wesi abu-abu | 100 | 0.13 | 0.15 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 |

| (<32HRC) | 80 | 0.17 | 0.02 | 0.26 | 0.32 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | 0.48 |

| 60 | 0.21 | 0.26 | 0.32 | 0.4 | 0.42 | 0.46 | 0.5 | 0.52 | 0.54 | 0.56 | |

| wesi paduan saka medium | 100 | 0.11 | 0.13 | 0.15 | 0.17 | 0.22 | 0.22 | 0.24 | 0.26 | 0.3 | 0.34 |

| kangelan pangolahan, | 80 | 0.15 | 0.18 | 0.23 | 0.26 | 0.28 | 0.34 | 0.35 | 0.4 | 0.4 | 0.43 |

| wesi nodular | 60 | 0.18 | 0.22 | 0.27 | 0.38 | 0.38 | 0.42 | 0.44 | 0.48 | 0.46 | 0.5 |

| (<28HRC) | |||||||||||

| wesi tuang paduan dhuwur sing ora bisa ditarik, | 90 | 0.06 | 0.08 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.23 | 0.23 |

| wesi nodular | 70 | 0.09 | 0.1 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.28 | 0.29 |

| (<28HRC) | 60 | 0.11 | 0.13 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.34 | 0.35 |

| Paduan aluminium tempa | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si<12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Cast aluminium alloy | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si<12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Cast aluminium alloy | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si>12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Tembaga, paduan tembaga | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (<200HB) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

manungsa waé:

Priksa manawa bagean kerja lan mesin stabil lan gunakake wadhah presisi, gunakake chuck hidrolik, chuck collet berkualitas tinggi.

Priksa manawa total indikasi run-out (TIR) kurang saka 0,02mm.

Kondisi pemotongan sing disaranake cocok kanggo aplikasi sing bisa larut ing banyu.

Yen ukuran alat ora ana ing meja. Mangga deleng lemari meja kanggo pilihan ukuran diameter agul-agul saka paramèter nglereni, nyetel paramèter nglereni miturut kahanan kerja nyata sak Processing.

Perusahaan kasebut nduweni lini produksi peralatan proses manufaktur blade lengkap saka persiapan bahan baku bubuk, nggawe cetakan, pressing, sintering tekanan, grinding, lapisan lan lapisan sawise perawatan. Fokus ing riset lan inovasi saka materi dhasar, struktur alur, tliti mbentuk lan nutupi lumahing carbide NC sisipan, lan saya mbenakake efficiency mesin, urip layanan lan situs nglereni liyane carbide NC sisipan. Sawise luwih saka sepuluh taun riset ilmiah lan inovasi, perusahaan wis nguwasani sawetara teknologi inti sawijining, duwe R&D lan kemampuan desain sawijining, lan bisa nyedhiyani produksi selaras kanggo saben customer.