- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

HJDK650 Tungsten carbide center drills

Tungsten carbide center drills

HJDK650 Tungsten carbide center drills

Kwesịrị ekwesị maka ịkụ ala ígwè, igwe anaghị agba nchara, ihe nkedo, ihe na-abụghị nke ígwè.

Isi ike HRA92.8

ihe: tungsten carbide

HJDK650 usoro-etiti drills

Okwu nkịtị:

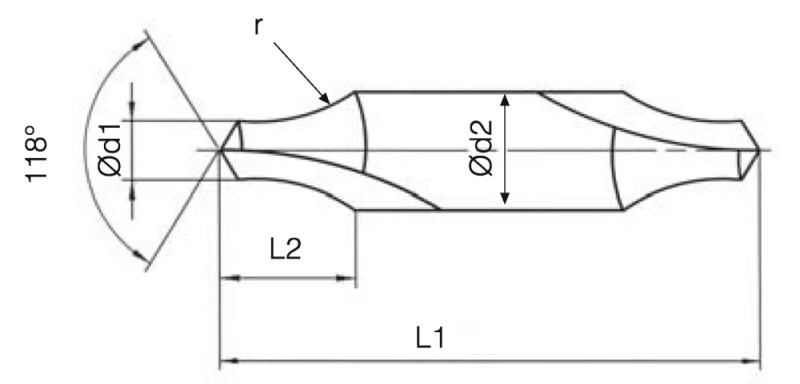

HJDK650 etiti akuakuzinwo na-aghọta a ọma nchikota n'etiti mgbawa eruba na akuakuzinwo òkè na nke na countersink òkè. Ọjà ha nwere ike nabata ibe n'ụzọ zuru ezu ma na-arụ ọrụ nke ọma iji chụpụ chips.center drills nwere ọnụ ọnụ na nsọtụ abụọ ahụ, ma nwee ọjà gburugburu. ike, anyị ebelatawo ogologo akuakuzinwo. Ọzọkwa iji kwụọ ụgwọ adịghị ike n'ebe njikọ dị n'etiti drill na countersink, ebe njikọ ahụ nwere R nke radius dị n'ime azụ-taper nke ọkpọ ahụ. Ha nwekwara ahịrị obosara.

Atụmatụ:

Kwesịrị ekwesị maka ịkụ ala ígwè, igwe anaghị agba nchara, ihe nkedo, ihe na-abụghị nke ígwè.

Stub chisel, ikike ime onwe ya mara mma.

Ebe radial, obere nguzogide igbutu.

Chamfer egbugbere ọnụ, ọnụego nri dị elu, arụmọrụ dị elu.

Nha oge niile:HJDK650 Fine Powder Center Drill Series

| Koodu ịtụ ahịa | Dayameta | Akụkụ | Ogologo ọjà | O.A.L. | Shank Dia. |

| HJDK650-0102 | 1 | 60° | 1.5 | 35 | 4 |

| HJDK650-0202 | 2 | 60° | 2.5 | 50 | 5 |

| HJDK650-0252 | 2.5 | 60° | 3 1 | 60 | 6.3 |

| HJDK650-03152 | 3.15 | 60° | 3.9 | 70 | 8 |

| HJDK650-0402 | 4 | 60° | 5 | 80 | 10 |

| HJDK650-0502 | 5 | 60° | 6.3 | 80 | 12 |

| HJDK650-0632 | 6.3 | 60° | 80 | 80 | 16 |

Ngwa ihe mejupụtara:

1. Njirimara anụ ahụ:

A) isi ike karịrị 92.8 HRA;

B) Njupụta dị ukwuu karịa ma ọ bụ hà nhata 14.2 g/cm³;

C) TRS karịrị 4200 N/mm²;

D) Enweghị ọnọdụ usoro ETA;

E) Enweghị mmetọ site na ihe ndị ọzọ;

F) Porosity = A00 / B00 / C00;

G) Nha ọka n'ụdị na agbanwe agbanwe. Ọ nweghị nha ọka nwere ike ibu karia akọwapụtara.

H) naanị ihe na-egbochi uto ọka chromium carbide.

2.A na-eji ngwá ọrụ niile nke mmepụta ihe, mkpuchi na Germany, Switzerland, ngwá ọrụ nhazi;

Oke ọrụ:

| Oke arụmọrụ n'etiti: | ||||||||||

| Ihe ọrụ | Ịbelata ọsọ | Ọnụego nri (mm/mpịakọta) | ||||||||

| (m/min) | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D20 | ||

| Low carbon steel, long chip (<125HB) | 130 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.15 | 0.17 | 0.2 | 0.24 | 0.26 | 0.3 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.26 | 0.3 | 0.32 | 0.35 | 0.4 | 0.45 | ||

| Carbon steel dị ala, mkpụkpụ mkpụkpụ, dị́ ụkpụrụ kpụkpụ ụla ( | 120 | 0.1 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.24 | 0.3 | 0.32 | 0.34 | 0.4 | 0.45 | ||

| Carbon ígwè dị elu na ọkara carbon steel ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Alloy steel, ọla ọla ọla ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Alloy steel, ihe ọla ọla (35-48HRC) | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| PH na ferritic, steels martensitic ( | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Gray iron(<32HRC) | 140 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Alloy ígwè nke isi nhazi ihe isi ike, ígwè nkedo nodular ( | 130 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 105 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Ígwè ihe nkedo dị elu aluoyi dị elu, ígwè nkedo nodular ( | 120 | 0.1 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.28 | |

| 90 | 0.16 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.29 | ||

| 60 | 0.22 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.35 | ||

| Aluminom alloy arụrụ arụ (Si | 150 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Nkedo aluminium alloy (Si | 150 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 120 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Nkedo aluminium alloy (Si>12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| 12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

Ọla kọpa, ọla kọpa alloy (

Nlebara anya:

Jide n'aka na mpempe ọrụ na igwe kwụsiri ike ma jiri njide ziri ezi, jiri chucks hydraulic, akwa kollet chucks dị elu.

Gbaa mbọ hụ na ngụkọta egosipuchara (TIR) erughị 0.02mm.

Ọnọdụ ịkpụ a tụrụ aro dabara adaba maka itinye mmiri soluable.

The ụlọ ọrụ nwere zuru ezu agụba n'ichepụta usoro akụrụngwa mmepụta akara si ntụ ntụ akụrụngwa nkwadebe, ebu ime, ịpị, sintering nrụgide, egweri, mkpuchi na mkpuchi post-ọgwụgwọ. Ọ na-elekwasị anya na nyocha na ọhụrụ nke isi ihe, uzo Ọdịdị, nkenke akpụ na elu mkpuchi nke carbide NC inserts, na mgbe niile mma machining arụmọrụ, ọrụ ndụ na ndị ọzọ ọnwụ Njirimara nke carbide NC inserts. Mgbe ihe karịrị afọ iri nke nnyocha sayensị na ọhụrụ, ụlọ ọrụ amụtala ọnụ ọgụgụ nke onwe teknụzụ isi, nwere onwe R&D na imewe ike, na ike inye ahaziri mmepụta maka onye ọ bụla ahịa.