- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

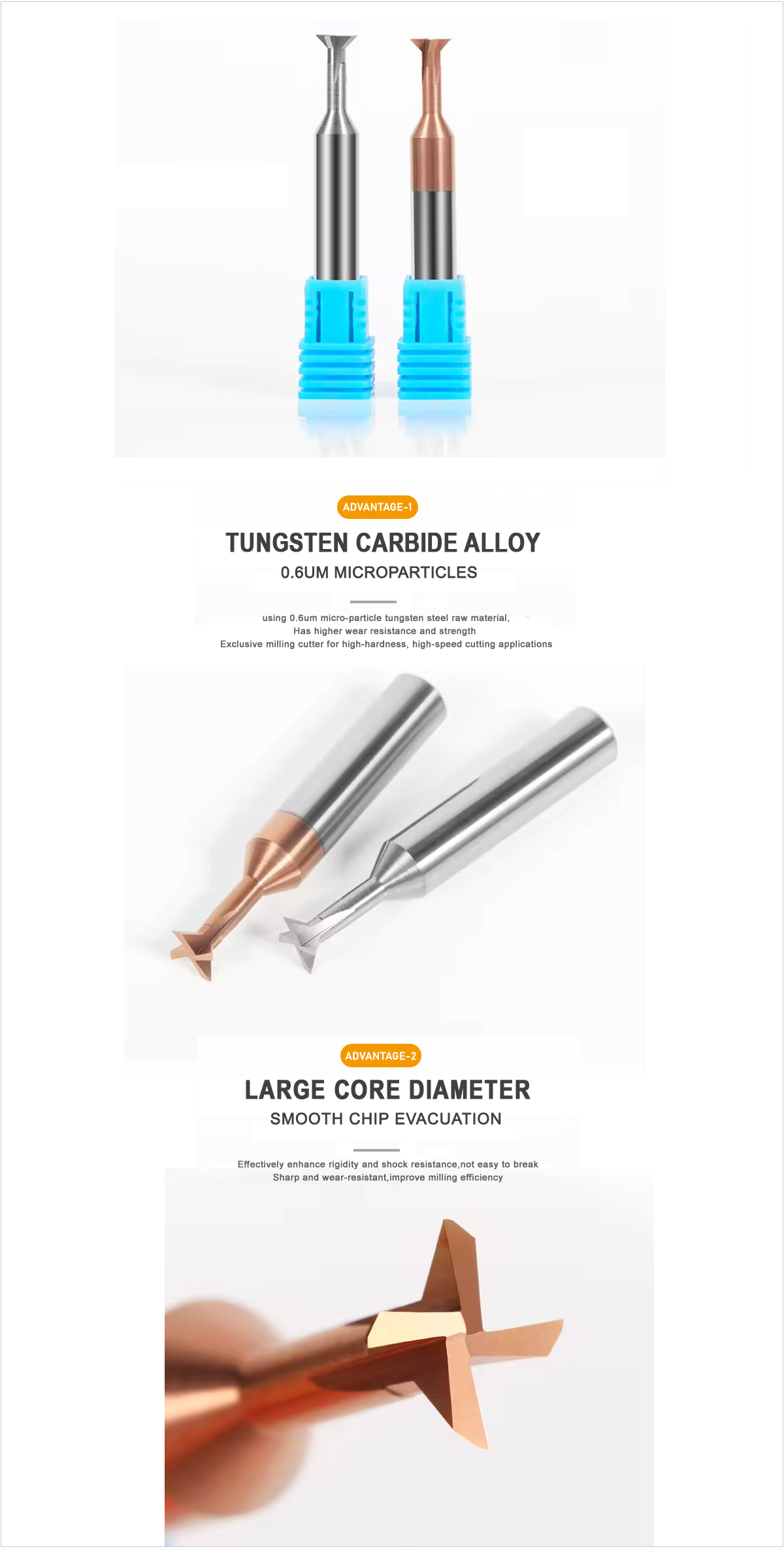

I-CNC Engokwezifiso Engajwayelekile I-Solid Carbide Dovetail Yakha I-Endmill T-slot Milling Cutter

CNC Amathuluzi Steel Aluminium Dovetail Groove Cutter T Slot

I-4-edge dovetail milling cutter

I-Dovetail End Milling Cutter eyenziwe ngokwezifiso

Isebenza ngokukhethekile ekukhiqizweni kohlobo lwe-T Custom Non-standard Dovetail Cnc Tungsten Steel

| Igama | I-Dovetail Groove Trough T Slot T-Slot T-Milling Cutter |

| Okubalulekile | I-carbide enosimende |

| Ukugqoka | I-AITiN/eyenziwe ngokwezifiso |

| I-engeli | 30°/45°/60°/90° |

| Ubude bubonke | 50-60mm noma ngezifiso |

| Ifanele | Insimbi engagqwali, Carbon Steel, Mold steel, Cast Iron,i-aluminium |

| Isicelo | I-side milling slotting, slot emise okwe-T, i-deep slotting, ukugaya indiza |

| Yonke imininingwane. kungenziwa ngokwezifiso | |

Izinzuzo zethu:

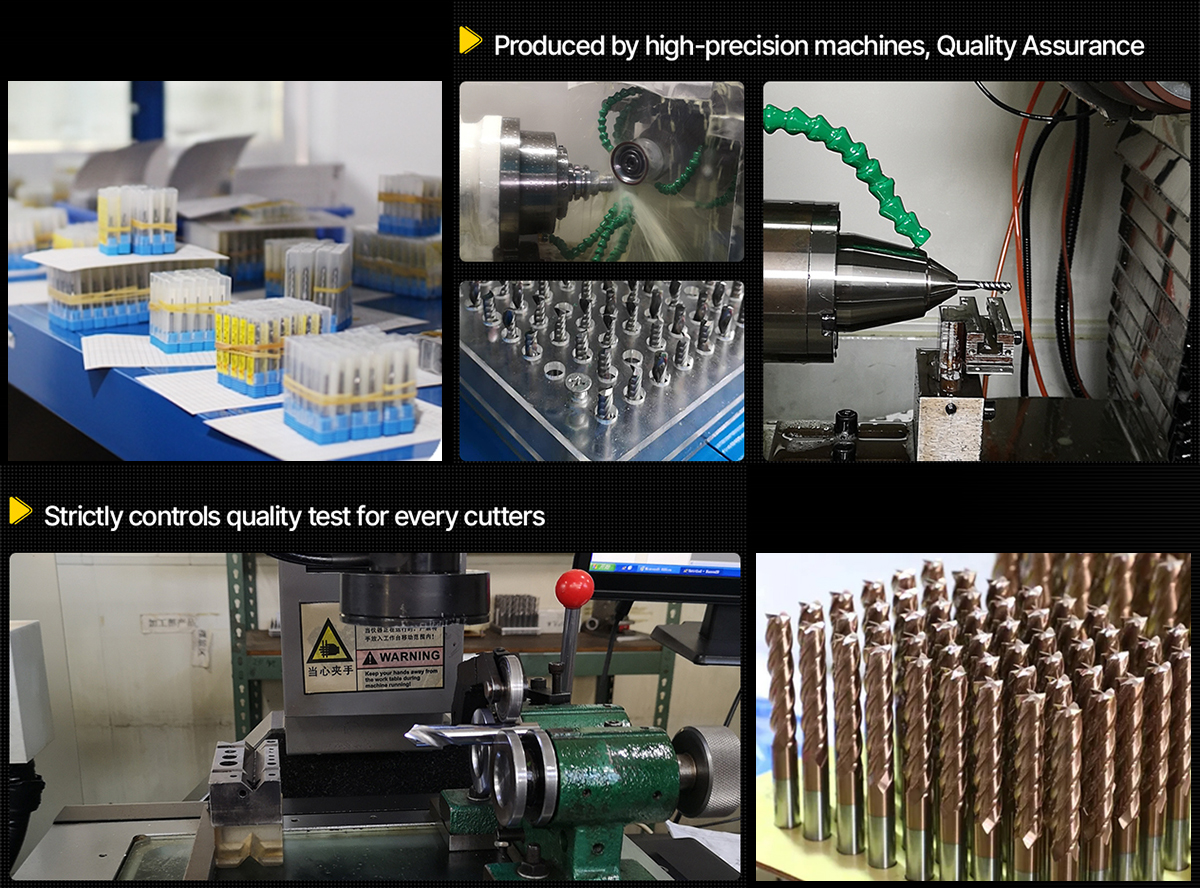

Ithimba lochwepheshe lokukhiqiza: Yiba nesipiliyoni seminyaka engaphezu kwe-10 sokukhiqiza kufayili ye-carbide.

Ukulethwa okusheshayo okusekelwe emandleni aphezulu okukhiqiza.

Uhlelo oluqinile lokulawula ikhwalithi: Qinisekisa ukuthi umkhiqizo wethu useqophelweni elihle nelizinzile.

Umuzwa ocebile emikhiqizweni eyenziwe ngokwezifiso.

Ukwesekwa kobuchwepheshe: Kukusiza ukuthi uthole isixazululo esingcono kakhulu.

T-slot Dovetail End Mills

Lezi zisiki eziyisipesheli zakhiwe ngemishini nezindlela ezisezingeni eliphezulu, zenza amakhasimende ethu abe nesipiliyoni esihle se-T slot. Idinga ukubamba ithuluzi eliqinile futhi isebenze kahle ukugwema ukuphuka. Umkhiqizo onokwemboza owokucutshungulwa kwensimbi kanye nezingenalutho ze-aluminium.

I-Professional Carbide End Mill Manufacture

Usayizi (okujwayelekile nokungajwayelekile)

Okujwayelekile:

Izisiki zethu ezijwayelekile zokugaya i-carbide zimboza ububanzi ukusuka ku-2mm ukuya ku-12mm ezihlangabezana nokuphathwa kokukhiqiza emhlabeni jikelele kanye namazinga ekhwalithi.

Okungajwayelekile:

Imboni yethu ingakwazi ukwenza imikhiqizo engajwayelekile ngokomdwebo wobuchwepheshe noma amasampula.

Usayizi ojwayelekile:

| Ukucaciswa | ||||||

| I-Mill Diameter D1/(mm) | I-engeli | Mill Height H/(mm) | Ububanzi bokugwema d/(mm) | Ubude Bentamo h/(mm) | I-Shank Diameter D2/(mm) | Ubude Bebonke L/(mm) |

| 2 | 60 | 0.32 | 0.9 | 4 | 4 | 50 |

| 3 | 60 | 0.47 | 1.4 | 6 | 4 | 50 |

| 4 | 60 | 0.62 | 1.9 | 8 | 4 | 50 |

| 5 | 60 | 0.79 | 2.3 | 10 | 6 | 50 |

| 6 | 60 | 0.94 | 2.8 | 10 | 6 | 50 |

| 8 | 60 | 1.29 | 3.6 | 12 | 8 | 60 |

| 10 | 60 | 1.61 | 4.5 | 15 | 10 | 60 |

| 12 | 60 | 1.94 | 5.4 | 18 | 12 | 60 |

| 2 | 45 | 0.55 | 0.9 | 4 | 4 | 50 |

| 3 | 45 | 0.8 | 1.4 | 6 | 4 | 50 |

| 4 | 45 | 1.05 | 1.9 | 8 | 4 | 50 |

| 5 | 45 | 1.35 | 2.3 | 10 | 6 | 50 |

| 6 | 45 | 1.6 | 2.8 | 10 | 6 | 50 |

| 8 | 45 | 2.2 | 3.6 | 12 | 8 | 60 |

| 10 | 45 | 2.75 | 4.5 | 15 | 10 | 60 |

| 12 | 45 | 3.3 | 5.4 | 18 | 12 | 60 |

| 2 | 30 | 0.96 | 0.9 | 4 | 4 | 50 |

| 3 | 30 | 1.4 | 1.4 | 6 | 4 | 50 |

| 4 | 30 | 1.84 | 1.9 | 8 | 4 | 50 |

| 5 | 30 | 2.37 | 2.3 | 10 | 6 | 50 |

| 6 | 30 | 2.81 | 2.8 | 10 | 6 | 50 |

| 8 | 30 | 3.86 | 3.6 | 12 | 8 | 60 |

| 10 | 30 | 4.82 | 4.5 | 15 | 10 | 60 |

| 12 | 30 | 5.79 | 5.4 | 18 | 12 | 60 |

Le nkampani inomugqa ophelele wokukhiqiza wemishini yokukhiqiza i-blade kusuka ekulungiseleleni impahla eluhlaza, ukwenza isikhunta, ukucindezela, ukucindezela ukucindezela, ukugaya, ukumboza kanye nokuhlanganisa ngemva kokwelashwa. Igxile ocwaningweni nasekusungulweni kwezinto eziyisisekelo, ukwakheka kwe-groove, ukunemba kwesakhiwo kanye nokunameka kwangaphezulu kokufakwa kwe-carbide NC, futhi ithuthukisa njalo ukusebenza kahle kwemishini, impilo yesevisi kanye nezinye izakhiwo zokusika zokufakwa kwe-carbide NC. Ngemva kweminyaka engaphezu kweshumi yocwaningo lwesayensi nokusungula izinto ezintsha, inkampani isikwazile ubuningi bobuchwepheshe obuyisisekelo obuzimele, inamakhono azimele we-R&D kanye nokuklama, futhi ingahlinzeka ngokukhiqiza okwenziwe ngezifiso kukhasimende ngalinye.