- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

HJDK650 Tungsten carbide center drills

Ukuzivocavoca kwesikhungo se-tungsten carbide

HJDK650 Tungsten carbide center drills

Ifanele ukubhola insimbi, insimbi engagqwali, insimbi ecijile, impahla engeyona insimbi.

Ukuqina HRA92.8

Material: Tungsten carbide

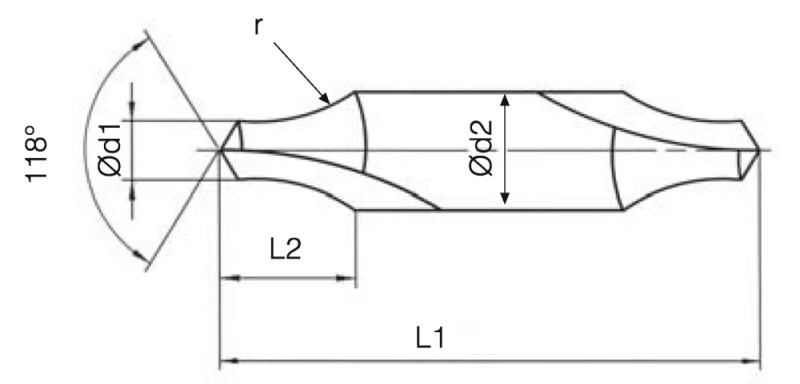

HJDK650 series-cent drills

Isitatimende esiqondile:

Ukubhoboza okuphakathi kwe-HJDK650 kuthola inhlanganisela enhle phakathi kokugeleza kwe-chip engxenyeni yokubhoboza naleyo esengxenyeni kasinki. Imitshingo yazo ingawamukela ngokugcwele ama-chips futhi isebenze kahle ukuze ikhiphe ama-chips.Izindawo zokuzibhoboza ezimaphakathi zinemiphetho yokusika emikhawulweni yomibili, futhi zinemitshingo evunguzayo.Ngenxa yokukhishwa kahle kwe-chip, izinkinga ezinjalo ziba zincane njengoba amathuluzi ephuka ngenxa yokuvala ama-chip. amandla, sinciphise ubude bokubhoboza. Ukuqhubeka nokunxephezela ubuthakathaka endaweni yokuxhuma phakathi kwe-drill kanye ne-countersink, iphoyinti lokuxhuma lino-R okuyirediyasi engaphakathi kwe-taper yangemuva ye-drill. Futhi banomugqa obanzi.

Izici:

Ifanele ukubhola insimbi, insimbi engagqwali, insimbi ecijile, impahla engeyona insimbi.

Ishishi le-Stub, ikhono elihle lokuzicabangela wena.

Iphoyinti le-radial, ukumelana nokusika okuncane.

I-Lip chamfer, izinga eliphezulu lokudla, ukusebenza kahle okuphezulu.

Usayizi ojwayelekile:HJI-DK650 Fine Powder Center Drill Series

| I-oda ikhodi | Ububanzi | I-engeli | Ubude womtshingo | O.A.L. | Shank Dia. |

| HJDK650-0102 | 1 | 60° | 1.5 | 35 | 4 |

| HJDK650-0202 | 2 | 60° | 2.5 | 50 | 5 |

| HJDK650-0252 | 2.5 | 60° | 3 1 | 60 | 6.3 |

| HJDK650-03152 | 3.15 | 60° | 3.9 | 70 | 8 |

| HJDK650-0402 | 4 | 60° | 5 | 80 | 10 |

| HJDK650-0502 | 5 | 60° | 6.3 | 80 | 12 |

| HJDK650-0632 | 6.3 | 60° | 80 | 80 | 16 |

Ukwakhiwa kwethuluzi:

1.Izakhiwo Zomzimba:

A) Ubunzima obukhulu noma obulingana no-92.8 HRA;

B) Ukuminyana kukhulu noma kulingana no-14.2 g/cm³;

C) I-TRS enkulu noma elingana no-4200 N/mm²;

D) Mahhala esimweni sesigaba se-ETA;

E) Akukho ukungcoliswa ezinye izinto;

F) I-Porosity = A00 / B00 / C00 ;

G) Usayizi wokusanhlamvu olinganayo futhi ongaguquki. Awekho usayizi wokusanhlamvu ongaba mkhulu kunokushiwo.

H) I-Chromium carbide growth inhibitor kuphela.

2.Wonke amathuluzi okukhiqiza, ama-coatings asetshenziswa eJalimane, eSwitzerland, imishini yokucubungula;

Ipharamitha yokusebenza:

| Ipharamitha yokusebenza yokubhola phakathi: | ||||||||||

| I-Workpeice material | Ukusika isivinini | Isilinganiso sokuphakelayo (mm/rev) | ||||||||

| (m/min) | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D20 | ||

| Low carbon steel, long chip (<125HB) | 130 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.15 | 0.17 | 0.2 | 0.24 | 0.26 | 0.3 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.26 | 0.3 | 0.32 | 0.35 | 0.4 | 0.45 | ||

| Insimbi yekhabhoni ephansi, isinqamuleli , insimbi esika kalula ( | 120 | 0.1 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.24 | 0.3 | 0.32 | 0.34 | 0.4 | 0.45 | ||

| Insimbi yekhabhoni ephezulu kanye nensimbi yekhabhoni ephakathi ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Insimbi ye-alloy, ithuluzi insimbi ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Insimbi ye-alloy, insimbi yethuluzi (35-48HRC) | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| I-PH kanye ne-ferritic, insimbi ye-martensitic ( | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Gray iron(<32HRC) | 140 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| I-alloy ayoni yobunzima bokucubungula okumaphakathi, i-nodular cast iron ( | 130 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 105 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| I-iron engakholeki phezulu i-alloy cast cast, nodular cast iron ( | 120 | 0.1 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.28 | |

| 90 | 0.16 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.29 | ||

| 60 | 0.22 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.35 | ||

| Ingxubevange eyenziwe ye-aluminium (Si | 150 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Cast aluminium alloy (Si | 150 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 120 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Cast aluminium alloy (Si>12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| 12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

Ithusi, ingxubevange yethusi (

Qaphela:

Qiniseka ukuthi ucezu lomsebenzi nomshini uzinzile futhi usebenzisa isibambi esinembayo, sebenzisa ama-chuck asebenza ngogesi, ama-collet chucks ekhwalithi ephezulu.

Qiniseka ukuthi isamba esikhonjisiwe sokuphuma(TIR) singaphansi kuka-0.02mm.

Isimo sokusika esinconyiwe sifanelekile ukusebenzisa amanzi ancibilikayo.

Le nkampani inomugqa ophelele wokukhiqiza wemishini yokukhiqiza i-blade kusuka ekulungiseleleni impahla eluhlaza, ukwenza isikhunta, ukucindezela, ukucindezela ukucindezela, ukugaya, ukumboza kanye nokuhlanganisa ngemva kokwelashwa. Igxile ocwaningweni nasekusungulweni kwezinto eziyisisekelo, ukwakheka kwe-groove, ukunemba kwesakhiwo kanye nokunameka kwangaphezulu kokufakwa kwe-carbide NC, futhi ithuthukisa njalo ukusebenza kahle kwemishini, impilo yesevisi kanye nezinye izakhiwo zokusika zokufakwa kwe-carbide NC. Ngemva kweminyaka engaphezu kweshumi yocwaningo lwesayensi nokusungula izinto ezintsha, inkampani isikwazile ubuningi bobuchwepheshe obuyisisekelo obuzimele, inamakhono azimele we-R&D kanye nokuklama, futhi ingahlinzeka ngokukhiqiza okwenziwe ngezifiso kukhasimende ngalinye.