- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

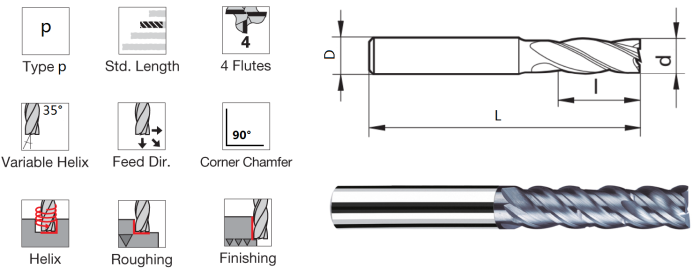

I-F4 F2 H Elungiselelwe Ukuphela Kwemishini Yezinsimbi Eziqinile

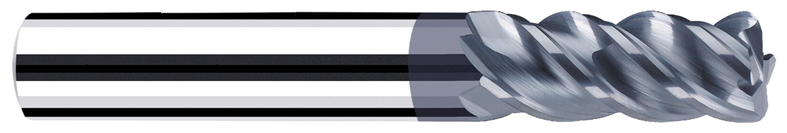

I-End Mill Yezinsimbi Eziqinile (48-60 HRC)

I-HJMJ600 End Mill Yezinsimbi Eziqinile (48-60 HRC)

ukufakwa: Okwezinsimbi eziqinile (48-60 HRC) zokuqeda.

I-Universal High Performance Coating AlCrSiN

F4 F2

Isitatimende sangempela:

I-End mill for die isetshenziswa kakhulu, ingafakwa futhi isetshenziswe kumathuluzi womoya noma kagesi, ukusebenza kahle kokukhiqiza nokuqina kunesondo lokugaya futhi kukhuphule inani lezikhathi ifayela.

Izici:

1.Ukuqina okuphezulu, ukuqina okuphezulu kwe-matrix, idizayini ekhethekile ye-engeli kanye nokwelashwa konqenqema, okukhethekile kwezinsimbi eziqinile ezizishoyo.

2.Ngezinsimbi eziqinile (48-60 HRC) zokuqeda.

3.Kunconyiwe ukusebenzisa umoya noma ukupholisa inkungu kawoyela.

Usayizi ojwayelekile:

1.4 Flute End Mills

| I-oda ikhodi | Ngaphandle Ububanzi | Ubude Bomtshingo | Ubude Bonke | I-Shank Diameter |

| (d) | (L) | (D) | ||

| HJMJ600-4F-D010-L050 | 1.0 | 3.0 | 50 | 4 |

| HJMJ600-4F-D015-L050 | 1.5 | 4.5 | 50 | 4 |

| HJMJ600-4F-D020-L050 | 2.0 | 6.0 | 50 | 4 |

| HJMJ600-4F-D025-L050 | 2.5 | 7.0 | 50 | 4 |

| HJMJ600-4F-D030-L050 | 3.0 | 8.0 | 50 | 4 |

| HJMJ600-4F-D035-L050 | 3.5 | 10.0 | 50 | 4 |

| HJMJ600-4F-D040-L050 | 4.0 | 11.0 | 50 | 4 |

| HJMJ600-4F-D050-L050 | 5.0 | 13.0 | 50 | 6 |

| HJMJ600-4F-D060-L050 | 6.0 | 16.0 | 50 | 6 |

| HJMJ600-4F-D070-L060 | 7.0 | 17.0 | 60 | 8 |

| HJMJ600-4F-D080-L060 | 8.0 | 20.0 | 60 | 8 |

| HJMJ600-4F-D090-L075 | 9.0 | 25.0 | 75 | 10 |

| HJMJ600-4F-D100-L075 | 10.0 | 25.0 | 75 | 10 |

| HJMJ600-4F-D110-L075 | 11.0 | 28.0 | 75 | 12 |

| HJMJ600-4F-D120-L075 | 12.0 | 30.0 | 75 | 12 |

| HJMJ600-4F-D140-L080 | 14.0 | 35.0 | 80 | 14 |

| HJMJ600-4F-D160-L100 | 16.0 | 45.0 | 100 | 16 |

| HJMJ600-4F-D180-L100 | 18.0 | 48.0 | 100 | 18 |

| HJMJ600-4F-D200-L100 | 20.0 | 50.0 | 100 | 20 |

2. 2 Flute Corner Radius End Mills

| Ngaphandle Ububanzi | R | Ubude Bomtshingo | Ubude Bonke | I-Shank Diameter | |

| (d) | (l) | (L) | (D) | ||

| HJMJ600-2F-010-02 | 1 | 0.2 | 2 | 50 | 4 |

| HJMJ600-2F-015-02 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ600-2F-015-03 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ600-2F-020-02 | 2 | 0.2 | 4 | 50 | 4 |

| HJMJ600-2F-020-05 | 2 | 0.5 | 4 | 50 | 4 |

| HJMJ600-2F-025-02 | 2.5 | 0.2 | 5 | 50 | 4 |

| HJMJ600-2F-025-05 | 2.5 | 0.5 | 5 | 50 | 4 |

| HJMJ600-2F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ600-2F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ600-2F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ600-2F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ600-2F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ600-2F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ600-2F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ600-2F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ600-2F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ600-2F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ600-2F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ600-2F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ600-2F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ600-2F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ600-2F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ600-2F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ600-2F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ600-2F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ600-2F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ600-2F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ600-2F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ600-2F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ600-2F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ600-2F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ600-2F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ600-2F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ600-2F-120-20 | 12 | 20 | 24 | 75 | 12 |

| HJMJ600-2F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ600-2F-120-30 | 12 | 3 | 24 | 75 | 12 |

3.4 Imishini Yokuqeda Ikhona Lomtshingo

| Ngaphandle Ububanzi | R | Ubude Bomtshingo | Ubude Bonke | I-Shank Diameter | |

| (d) | (l) | (L) | (D) | ||

| HJMJ600-4F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ600-4F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ600-4F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ600-4F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ600-4F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ600-4F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ600-4F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ600-4F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ600-4F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ600-4F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ600-4F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ600-4F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ600-4F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ600-4F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ600-4F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ600-4F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ600-4F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ600-4F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ600-4F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ600-4F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ600-4F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ600-4F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ600-4F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ600-4F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ600-4F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ600-4F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ600-4F-120-20 | 12 | 2 | 24 | 75 | 12 |

| HJMJ600-4F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ600-4F-120-30 | 12 | 3 | 24 | 75 | 12 |

Ukwakheka kwezinto zamathuluzi

I-Universal High Performance Coating AlCrSiN

Izimpawu kanye nomsebenzi

1,Ukukhiqiza kukhuphuka ngenxa yesivinini sokusika esiphezulu kakhulu kanye nokuphakelayo kwezinhlelo zokusebenza kunhlobonhlobo yezinto.Ukukhiqiza okuthuthukisiwe ngokuphawulekayo.

I-2, Idizayini ethile yesakhiwo iletha ukulingana okuhle phakathi kokuqina, ukuzinza kwe-thermo-shock kanye nengcindezi eyinsalela.

Ipharamitha yokusebenza:

| HJMJ600End mill for die Operation parameter: | |||||||||||

| HJMJ600-S4 For Alloy Steel,Hardened Steel-Side Milling | |||||||||||

| Amabanga | Umumo wethuluzi | I-Workpiece Material | Ukujula | VC | Ithuluzi Ububanzi | 2 | 4 | 6 | 8 | 10 | 12 |

| S4 | (mm) | m/min | (mm) | ||||||||

| HJMJ600 | Isikwele, irediyasi ekhoneni | HRC58 | ap≤1D | 120 | Speed(min-1) | 19100 | 9550 | 6730 | 4780 | 3820 | 3190 |

| ae≤0.05D | Okuphakelayo isivinini | 760 | 760 | 760 | 760 | 730 | 710 | ||||

| (mm/min) | |||||||||||

| HRC58-62 | ap≤0.7D | 90 | Isivinini | 15920 | 11940 | 7960 | 5970 | 4780 | 3980 | ||

| (min-1) | |||||||||||

| ae≤0.03D | Okuphakelayo isivinini | 510 | 720 | 730 | 720 | 730 | 670 | ||||

| (mm/min) | |||||||||||

Qaphela:

Qiniseka ukuthi ucezu lomsebenzi nomshini uzinzile futhi usebenzisa isibambi esinembayo.

Sicela ulungise isivinini, okuphakelayo kanye nokusika ukujula ngokwezimo zangempela zokusika.

Izimo zokugaya zingezesigayo lapho ubude bethuluzi bungaphansi kuka-4*D(mill dia). Uma ubude be-overhang bamathuluzi bubude, sicela ulungise isivinini, okuphakelayo nokujula kokusika.

Le nkampani inomugqa ophelele wokukhiqiza wemishini yokukhiqiza i-blade kusuka ekulungiseleleni impahla eluhlaza, ukwenza isikhunta, ukucindezela, ukucindezela ukucindezela, ukugaya, ukumboza kanye nokuhlanganisa ngemva kokwelashwa. Igxile ocwaningweni nasekusungulweni kwezinto eziyisisekelo, ukwakheka kwe-groove, ukunemba kwesakhiwo kanye nokunameka kwangaphezulu kokufakwa kwe-carbide NC, futhi ithuthukisa njalo ukusebenza kahle kwemishini, impilo yesevisi kanye nezinye izakhiwo zokusika zokufakwa kwe-carbide NC. Ngemva kweminyaka engaphezu kweshumi yocwaningo lwesayensi nokusungula izinto ezintsha, inkampani isikwazile ubuningi bobuchwepheshe obuyisisekelo obuzimele, inamakhono azimele we-R&D kanye nokuklama, futhi ingahlinzeka ngokukhiqiza okwenziwe ngezifiso kukhasimende ngalinye.