- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

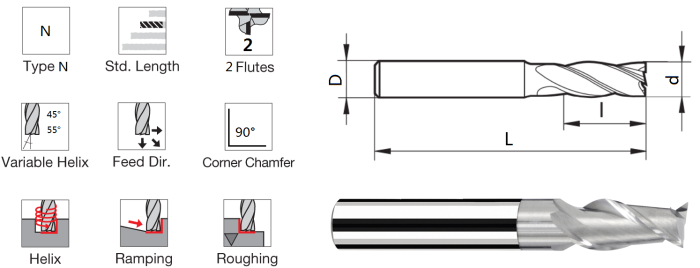

I-F2 F3 End Mill yomshini wejubane eliphezulu we-aerospace aluminium alloys

Okwe-Aerospace Aluminium Alloy

I-HJA650 End Mill Ye-Aerospace Aluminium Alloy

Ifanele ukwenziwa kwemishini kwesivinini esiphezulu kwama-alloys e-aerospace aluminium

I-Carbide enosimende ene-Ultra-fine, ukumelana nokugqokwa okuphezulu kanye nokuqina

F2 F3

Isitatimende esiqondile:

Idizayini ye-Aero-Tech enemitshingo emithathu yenzelwe ukwenziwa kwemishini eyongayo yezinsimbi ezivamile, insimbi engagqwali, izinsimbi ezixubile eziphakeme kanye ne-titanium ne-nickel alloys. Zonke izigayo zokugcina ze-Aero-Tech zinokuvikeleka kwekhona elincane lempilo yamathuluzi eyandisiwe. Itholakala ngezingubo ezimboziwe noma ezigqamile eziqediwe njengezindinganiso ezigcwele.

Isici:

Ifanele ukwenziwa kwemishini kwesivinini esiphezulu kwama-alloys e-aerospace aluminium

I-Carbide enosimende ene-Ultra-fine, ukumelana nokugqokwa okuphezulu kanye nokuqina.

Idizayini ekhethekile yokulinganisa nokunemba ngebhalansi N=25000RPM, G2.0 ilungele ukusika isivinini esikhulu.

I-HJA650 inezimbobo zokupholisa zangaphakathi ezinikeza isenzo sokupholisa esisebenza ngempumelelo ngendawo yokusika yomshini wejubane eliphezulu.

Imiphetho ebukhali ehlukile ihlinzeka ngokusebenza okwengeziwe ekusebenzeni kahle kokushelela nokuqeda.

I-cavity milling esebenza kahle kakhulu enezinga lokususa lensimbi elingafika ku-800cc/min.

Usayizi ojwayelekile:

1. Izinhlayiya ze-Ultrafine ze2 umtshingo imishini yokuphela kwe-aluminium

| I-oda ikhodi | Ububanzi | Ubude womtshingo | O.A.L. | Shank Dia. |

| HJA650-0302 | 3 | 9.0 | 50 | 3 |

| HJA650-0102 | 1 | 4.0 | 50 | 4 |

| HJA650-0152 | 1.5 | 5.0 | 50 | 4 |

| HJA650-0202 | 2 | 6.0 | 50 | 4 |

| HJA650-0252 | 2.5 | 7.0 | 50 | 4 |

| HJA650-0302 | 3 | 9.0 | 50 | 4 |

| HJA650-0352 | 3.5 | 10.0 | 50 | 4 |

| HJA650-0402 | 4 | 12.0 | 50 | 4 |

| HJA650-0502 | 5 | 15.0 | 50 | 5 |

| HJA650-0102 | 1 | 4.0 | 50 | 6 |

| HJA650-0152 | 1.5 | 5.0 | 50 | 6 |

| HJA650-0202 | 2 | 6.0 | 50 | 6 |

| HJA650-0302 | 3 | 9.0 | 50 | 6 |

| HJA650-0402 | 4 | 12.0 | 50 | 6 |

| HJA650-0502 | 5 | 15.0 | 50 | 6 |

| HJA650-0620 | 6 | 18.0 | 50 | 6 |

| HJA650-0802 | 8 | 20.0 | 60 | 8 |

| HJA650-1002 | 10 | 30.0 | 75 | 10 |

| HJA650-1202 | 12 | 30.0 | 75 | 12 |

2.Izinhlayiya ze-Ultrafine ze-3 flute aluminium End mill

| I-oda ikhodi | Ububanzi | Ubude womtshingo | O.A.L. | Shank Dia. |

| HJA650-0303 | 3 | 9 | 50 | 3 |

| HJA650-0103 | 1 | 4 | 50 | 4 |

| HJA650-0153 | 1.5 | 5 | 50 | 4 |

| HJA650-0203 | 2 | 6.0 | 50 | 4 |

| HJA650-0253 | 2.5 | 7 | 50 | 4 |

| HJA650-0303 | 3 | 9 | 50 | 4 |

| HJA650-0353 | 3.5 | 10.0 | 50 | 4 |

| HJA650-0403 | 4 | 12 | 50 | 4 |

| HJA650-0503 | 5 | 15 | 50 | 5 |

| HJA650-0103 | 1 | 4 | 50 | 6 |

| HJA650-0153 | 1.5 | 5 | 50 | 6 |

| HJA650-0203 | 2 | 6 | 50 | 6 |

| HJA650-0253 | 2.5 | 7 | 50 | 6 |

| HJA650-0303 | 3 | 9 | 50 | 6 |

| HJA650-0403 | 4 | 12 | 50 | 6 |

| HJA650-0503 | 5 | 15 | 50 | 6 |

| HJA650-0603 | 6 | 18 | 50 | 6 |

| HJA650-0803 | 8 | 20 | 60 | 8 |

| HJA650-1003 | 10 | 30 | 75 | 10 |

| HJA650-1203 | 12 | 30 | 75 | 12 |

Ukwakhiwa kwethuluzi:

1. Izakhiwo Zomzimba:

A) Ubunzima obukhulu noma obulingana no-94 HRA;

B) Ukuminyana kukhulu noma kulingana no-14.6g/cm³;

C) I-TRS enkulu noma elingana no-4100 N/mm²;

2. Wonke amathuluzi okukhiqiza, ama-coatings asetshenziswa eJalimane, eSwitzerland, imishini yokucubungula;

Ipharamitha yokusebenza:

| HJA650 operation parameter of end mill for aerospace aluminum alloy:HJA650-RN2 | |||||||||

| HJA650 RN2 For Aerospace Aluminium Alloy-Side Milling | |||||||||

| Ibanga | Umumo wethuluzi | I-Workpiece Material | Ukujula | VC | Ithuluzi Ububanzi | 10 | 12 | 16 | 20 |

| RN2 | (mm) | m/min | (mm) | ||||||

| HJA650 | I-Aluminium alloy 7075,7050 (Si<6%) | ap≤0.25D | 400 | isivinini | 12000 | 10000 | 8000 | 7000 | |

| (300-500) | (min-1) | ||||||||

| ae≤0.5 | isilinganiso sokuphakelayo | 3600 | 3300 | 3200 | 3080 | ||||

| (mm/min) | |||||||||

Qaphela:

Qiniseka ukuthi ucezu lomsebenzi nomshini uzinzile futhi usebenzisa isibambi esinembayo.

Sicela ulungise isivinini, okuphakelayo kanye nokusika ukujula ngokwezimo zangempela zokusika.

Izimo zokugaya zingezesigayo lapho ubude bethuluzi bungaphansi kuka-4*D(mill dia). Uma ubude be-overhang bamathuluzi bubude, sicela ulungise isivinini, okuphakelayo nokujula kokusika.

Le nkampani inomugqa ophelele wokukhiqiza wemishini yokukhiqiza i-blade kusuka ekulungiseleleni impahla eluhlaza, ukwenza isikhunta, ukucindezela, ukucindezela ukucindezela, ukugaya, ukumboza kanye nokuhlanganisa ngemva kokwelashwa. Igxile ocwaningweni nasekusungulweni kwezinto eziyisisekelo, ukwakheka kwe-groove, ukunemba kwesakhiwo kanye nokunameka kwangaphezulu kokufakwa kwe-carbide NC, futhi ithuthukisa njalo ukusebenza kahle kwemishini, impilo yesevisi kanye nezinye izakhiwo zokusika zokufakwa kwe-carbide NC. Ngemva kweminyaka engaphezu kweshumi yocwaningo lwesayensi nokusungula izinto ezintsha, inkampani isikwazile ubuningi bobuchwepheshe obuyisisekelo obuzimele, inamakhono azimele we-R&D kanye nokuklama, futhi ingahlinzeka ngokukhiqiza okwenziwe ngezifiso kukhasimende ngalinye.