Ukuhlaziywa kokubunjwa kokufakwa kwe-carbide enosimende

Njengayo yonke imikhiqizo eyenziwe ngumuntu, ukukhiqizwa kwezindwani zokusika ezisindayo zensimbi kufanele kuqala kuxazulule inkinga yezinto ezingavuthiwe, okungukuthi, kunqume ukwakheka kanye nefomula yezinto ze-blade. Iningi lama-blades anamuhla enziwe nge-carbide enosimende, ehlanganiswe ikakhulukazi ne-tungsten carbide (WC) ne-cobalt (Co). I-WC iyizinhlayiya eziqinile ku-blade, futhi i-Co ingasetshenziswa njenge-binder ukuze ilolonge i-blade.

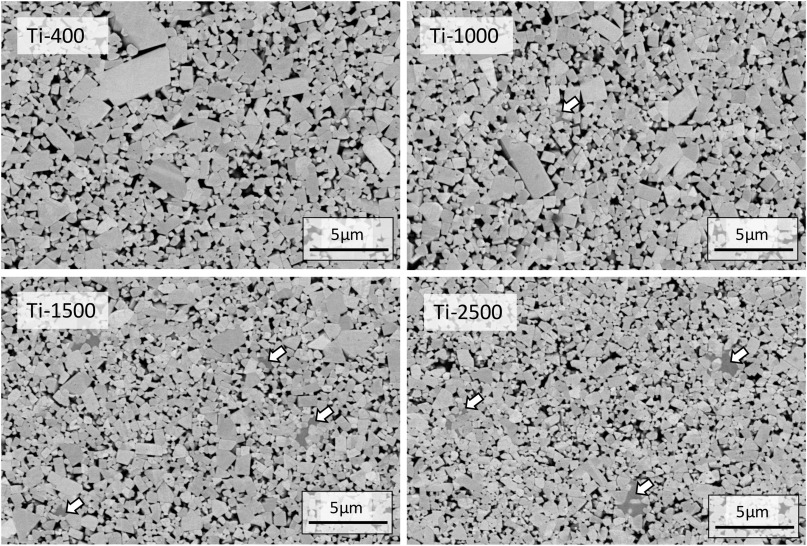

Indlela elula yokuguqula izakhiwo ze-carbide enosimende ukushintsha usayizi wokusanhlamvu wezinhlayiya ze-WC ezisetshenzisiwe. Usayizi wezinhlayiyana ezinkulu (3-5 μ m) Ubulukhuni bezinto ze-carbide zikasimende ezilungiselelwe izinhlayiya ze-WC ezino-C% ziphansi futhi kulula ukuzisebenzisa; Usayizi wezinhlayiyana ezincane (< 1 μ m) Izinhlayiya ze-WC zingakhiqiza izinto eziqinile ze-alloy ezinobunzima obuphakeme, ukumelana nokugqokwa okungcono, kodwa futhi nokuba brittleness okukhulu. Lapho kwenziwa izinto zensimbi ezinobunzima obuphakeme kakhulu, ukusetshenziswa kokufakwa kwe-carbide okusanhlamvu okusanhlamvu kungafinyelela imiphumela emihle yomshini. Ngakolunye uhlangothi, ithuluzi le-carbide eliqinile okusanhlamvu lisebenza kangcono ekusikeni kwezikhawu noma eminye imishini edinga ukuqina okuphezulu kwethuluzi.

Enye indlela yokulawula izici zokufakwa kwe-carbide enosimende ukushintsha ingxenye ye-WC kuya kokuqukethwe kwe-Co. Uma kuqhathaniswa ne-WC, ubulukhuni be-Co buphansi kakhulu, kodwa ukuqina kungcono. Ngakho-ke, ukunciphisa okuqukethwe kwe-Co kuzoholela ekuqineni okuphezulu. Yiqiniso, lokhu kuphinda kuphakamisa inkinga yokulinganisa okuphelele - ama-blade okuqina aphezulu anokumelana nokugqoka okungcono, kodwa ukuqina kwawo kukhulu. Ngokohlobo oluthile lokucubungula, ukukhetha usayizi wokusanhlamvu we-WC ofanelekile kanye nesilinganiso sokuqukethwe kwe-Co kudinga ulwazi olufanele lwesayensi nolwazi olucebile lokucubungula.

Ngokusebenzisa ubuchwepheshe bezinto ze-gradient, ukuvumelana phakathi kwamandla nokuqina kwe-blade kungagwenywa ngezinga elithile. Lobu buchwepheshe, obusetshenziswe kakhulu abakhiqizi bamathuluzi abakhulu emhlabeni, buhlanganisa ukusetshenziswa kwesilinganiso esiphezulu sokuqukethwe kwe-Co kungqimba yangaphandle ye-blade kunesendlalelo sangaphakathi. Ngokucacile, ungqimba lwangaphandle lwe-blade (ubukhulu 15-25 μ m) Khulisa okuqukethwe kwe-Co ukuze unikeze umsebenzi ofana "nendawo yebhafa", ukuze i-blade ikwazi ukumelana nomthelela othile ngaphandle kokuqhekeka. Lokhu kwenza umzimba wamathuluzi we-blade uthole izakhiwo ezihlukahlukene ezinhle kakhulu ezingafinyelelwa kuphela ngokusebenzisa i-carbide enosimende enamandla aphezulu.

Lapho usayizi wezinhlayiyana, ukwakheka kanye neminye imingcele yezobuchwepheshe yezinto zokusetshenziswa kunqunywa, inqubo yangempela yokukhiqiza yokusika okufakwayo ingaqalwa. Okokuqala, faka impushana ehambisanayo ye-tungsten, i-carbon powder ne-cobalt powder emshinini ocishe ulingane nowomshini wokuwasha, ugaye impushana ibe usayizi wezinhlayiyana ezidingekayo, bese uhlanganisa zonke izinhlobo zezinto ngokulinganayo. Phakathi nenqubo yokugaya, utshwala namanzi kwengezwa ukuze kulungiswe i-slurry emnyama. Khona-ke udaka lufakwa endaweni yokomisa isishingishane, bese uketshezi oluseludaka luyahwamuka ukuze kutholwe impushana eyisigaxa bese lugcinwa.

Enqubweni elandelayo yokulungiselela, i-prototype ye-blade ingatholakala. Okokuqala, i-powder elungisiwe ixubene ne-polyethylene glycol (PEG). Njenge-plasticizer, i-PEG ingakwazi ukuhlanganisa impushana ndawonye njengenhlama. Izinto ezisetshenziswayo zibe sezicindezelwa esimweni se-blade kudayi. Ngokwezindlela ezihlukene zokucindezela i-blade, ukucindezela kwe-axis eyodwa kungasetshenziselwa ukucindezela, noma ukucindezela kwe-multi axis kungasetshenziswa ukucindezela umumo we-blade kuma-engeli ahlukene.

Ngemuva kokuthola okungenalutho okucindezelwe, kufakwa esithandweni esikhulu somlilo futhi kushiswe ekushiseni okuphezulu. Enqubweni ye-sintering, i-PEG iyancibilika futhi ikhishwe engxube ye-billet, ishiya i-carbide blade eqediwe kancane. Uma i-PEG incibilika, i-blade incipha ibe ngusayizi wayo wokugcina *. Lesi sinyathelo senqubo sidinga ukubala okunembile kwezibalo, ngoba ukushwabana kwensingo kuhlukile ngokuya ngokuqanjwa kwezinto ezihlukene kanye nezilinganiso, futhi ukubekezelelana komkhiqizo oqediwe kuyadingeka ukuthi kulawulwe ngaphakathi kwama-microns amaningana.

Isikhathi sokuposa: 2023-01-15