Ukuhlukaniswa kanye nomsebenzi wamathuluzi okuguqula

Kunamathuluzi amaningi okusika empilweni yethu. Isibonelo, imimese, imimese yasekhishini namanye amathuluzi okusika ekhishini kanye namabhodi okusika ama-Ca (okuhlanza isithombo) konke okungamathuluzi okusika. Futhi, abasiki bephepha nabalola amapensela etafuleni, amasaha namapulani ebhokisini lamathuluzi, njll. nakho kungamathuluzi okusika. Lokho la mathuluzi afana ngakho ukuthi angakwazi ukushintsha ukuma kwezinto futhi akhiqize ama-chips okusika ngokusika nokusika., Ithuluzi lokusika iyithuluzi elenza into ibe seduze nesimo oyifunayo ngokusika. Amathuluzi okusika empilweni yethu asetshenziselwa ukucubungula izithelo, imifino kanye nezinkuni, futhi amathuluzi okusika asetshenziselwa ukucubungula izinto ezifana nensimbi ezinzima kunabo.

Inqubo yokukhiqiza ithuluzi lokusika

Okokuqala, i-tungsten carbide ne-cobalt kuhlanganiswa ukwenza impushana yezinto ezingavuthiwe, bese kuthi impushana eluhlaza ifakwe esikhunjeni sokugxiviza ukuze ibe nobulukhuni obufana noboshoki. Bese sinter at 1400 °. Ngale ndlela, i-carbide enosimende yenziwa. I-carbide enosimende inesici esinjalo kangangokuthi ivolumu yayo iba yingxenye yoqobo ngemuva kokucwiliswa. Ukuqina kwe-carbide esimende kuphakathi kwedayimane nesafire, futhi isisindo sayo sicishe siphindwe kabili kunesensimbi. Lapha, indlela yokucubungula i-carbide enosimende oqinile? Isondo lokugaya idayimane lisetshenziselwa ukugaya ukuze libe yisimo esifiselekayo.

Inqubo yokusika

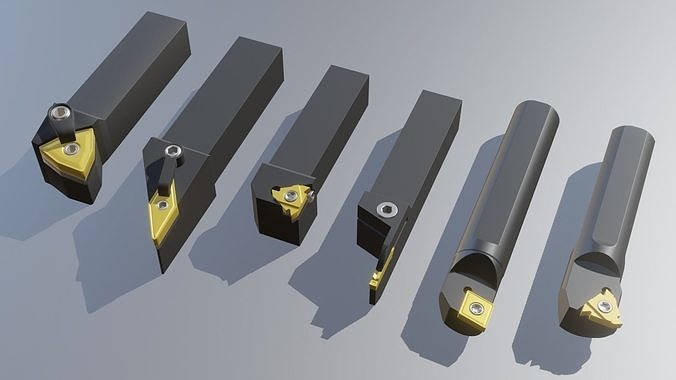

Isimo sokusika enqubweni yokusika. Uma ithuluzi lithinta ithuluzi lokusika, liyaphuka futhi libe ama-chips. Ngalesi sikhathi, ukushisa okukhiqizwa ngezinye izikhathi kufinyelela ngaphezu kwama-degree angu-800. Kule nqubo yokusika, ithiphu lethuluzi lizothinteka kakhulu futhi likhiqize ukushisa okuphezulu. I-carbide enosimende enamandla okuthwala aqinile kulezi zici ingamandla amakhulu wezinto zamathuluzi zanamuhla. Ama-blade anjalo angafakwa kubanikazi bamathuluzi ahlukahlukene, futhi angakhethwa ngokuvumelana nokuma kwe-workpiece kanye nendlela yokusika. Lokhu sikubiza nge-cutting edge blade indexable blade, osekuyinsakavukela yamathuluzi e-carbide enosimende ngendlela yethiphu eshintshwayo.

Yini ephendukayo

Amathuluzi okusika izinto eziyi-cylindrical ahlanganisa amathuluzi okuguqula ububanzi bangaphandle namathuluzi ayisicefe obubanzi bangaphakathi. Inqubo yokusika enethuluzi lokuguqula kanye nethuluzi eliyisicefe ibizwa ngokuthi inqubo yokuguqula, futhi ukujikeleza kwe-workpiece kuyisici senqubo yokuguqula. Ngokuyinhloko ibhekisela ekujikelezeni kwe-workpiece. Ithuluzi lomshini elicubungula i-workpiece libe yindingiliza libizwa ngokuthi i-lathe.

Isikhathi sokuposa: 2023-01-15