- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

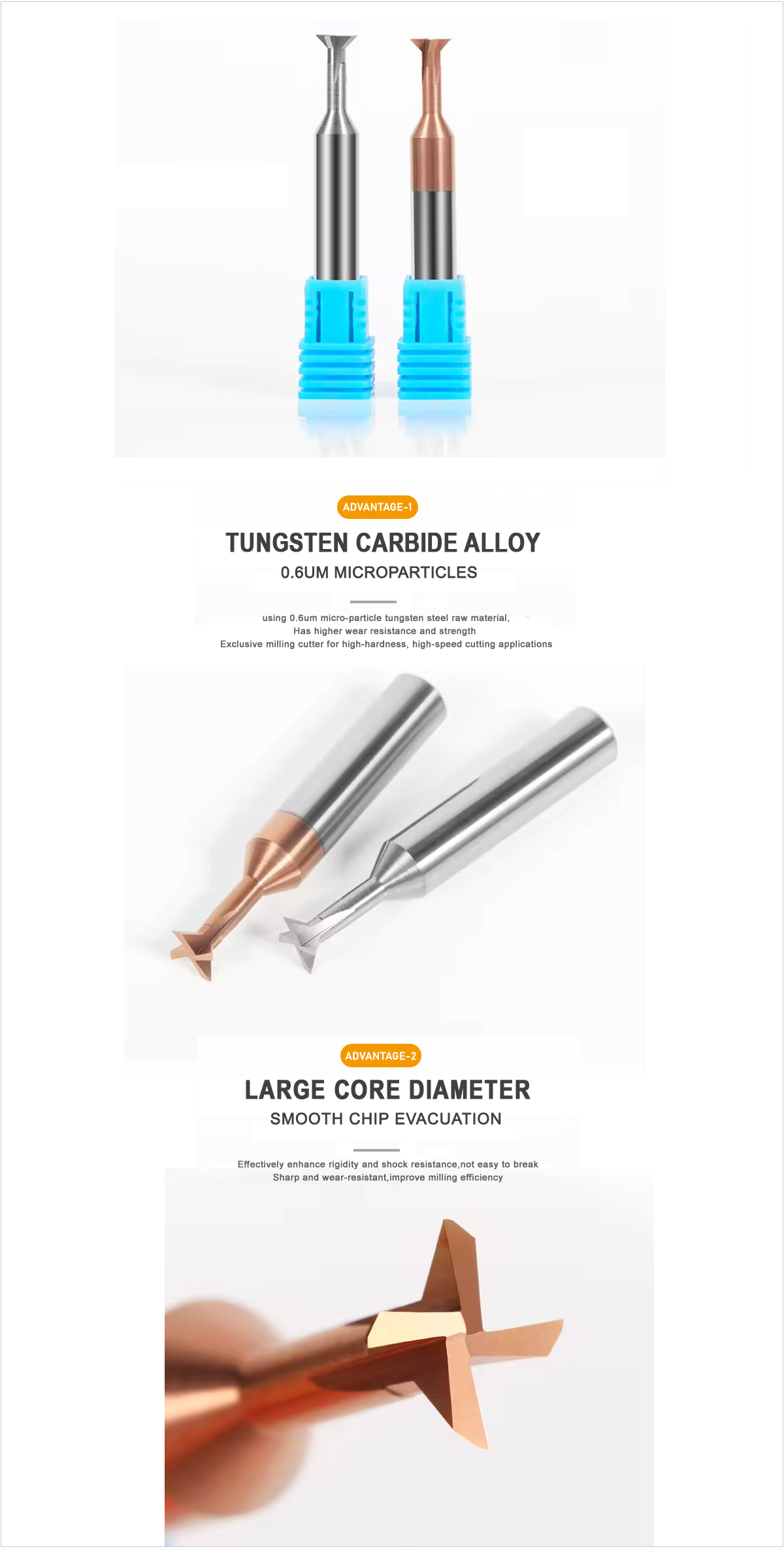

Ti adani CNC ti kii-bošewa ri to Carbide Dovetail Dida Endmill T-Iho milling cutter

CNC Tools Irin Aluminiomu Dovetail Groove ojuomi T Iho

4-eti dovetail milling ojuomi

Adani Non-bošewa Dovetail End milling ojuomi

Amọja ni iṣelọpọ ti Aṣa ti kii ṣe boṣewa T-iru Dovetail Cnc Tungsten Steel

| Oruko | Dovetail Groove Trough T Iho T-Iho T-milling ojuomi |

| Ohun elo | carbide ti a fi simenti |

| Aso | AITIN/ adani |

| Igun | 30°/45°/60°/90° |

| Lapapọ ipari | 50-60mm tabi adani |

| Dara Fun | Irin Alagbara, Irin Erogba, Irin Mold, Irin Simẹnti,aluminiomu |

| Ohun elo | Side milling slotting, T-sókè slotting, jin slotting, ofurufu milling |

| Gbogbo awọn alaye lẹkunrẹrẹ. le ti wa ni adani | |

Awọn anfani wa:

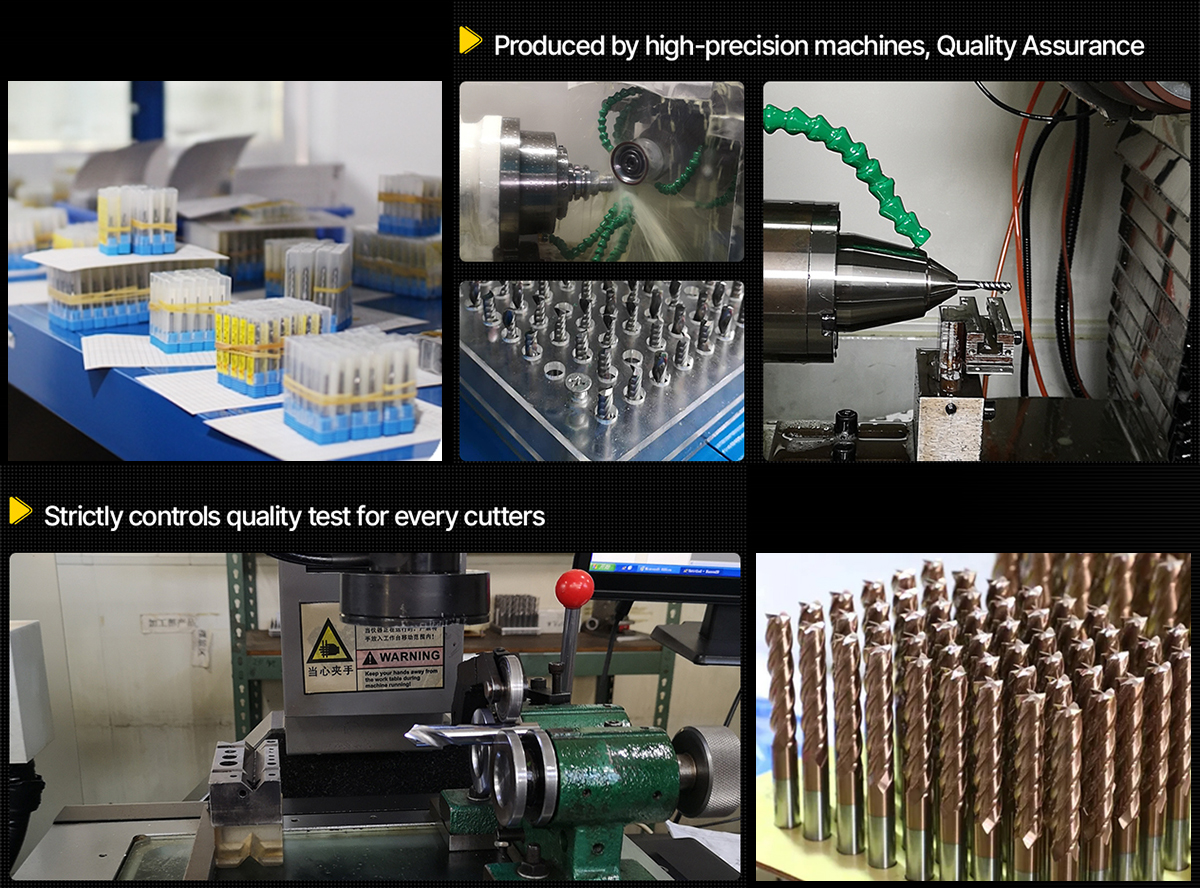

Ẹgbẹ ọjọgbọn fun iṣelọpọ: Ni iriri diẹ sii ju ọdun 10 fun iṣelọpọ lori faili carbide.

Ifijiṣẹ iyara ti o da lori agbara iṣelọpọ giga.

Eto iṣakoso didara to muna: Rii daju pe ọja wa ni didara to dara ati iduroṣinṣin.

Ọlọrọ iriri lori adani awọn ọja.

Atilẹyin imọ-ẹrọ: Ṣe iranlọwọ fun ọ lati gba ojutu ti o dara julọ.

T-Iho Dovetail Ipari Mills

Yi pataki cutters ti wa ni ṣelọpọ nipasẹ ipinle-ti-aworan ero ati awọn imuposi, jeki wa oni ibara ni ti o dara T slotting iriri. O nilo idaduro ọpa lile ati ṣiṣe daradara lati yago fun fifọ. Ọja pẹlu ti a bo ni fun irin processing ati òfo eyi fun aluminiomu.

Professional Carbide End ọlọ Manufacture

Iwọn (boṣewa & ti kii ṣe boṣewa)

Iwọnwọn:

Awọn gige milling carbide boṣewa wa bo iwọn ila opin lati 2mm si 12mm ipade iṣakoso iṣelọpọ agbaye ati awọn iṣedede didara.

Ti kii ṣe boṣewa:

Ile-iṣẹ wa le ṣe awọn ọja ti kii ṣe deede gẹgẹbi iyaworan imọ-ẹrọ tabi awọn apẹẹrẹ.

Iwọn deede:

| Sipesifikesonu | ||||||

| Mill Diameter D1/(mm) | Igun | Mill Giga H/(mm) | Iyara Opin d/(mm) | Gigun ọrun h/(mm) | Shank Diamita D2/(mm) | Lapapọ Gigun L/(mm) |

| 2 | 60 | 0.32 | 0.9 | 4 | 4 | 50 |

| 3 | 60 | 0.47 | 1.4 | 6 | 4 | 50 |

| 4 | 60 | 0.62 | 1.9 | 8 | 4 | 50 |

| 5 | 60 | 0.79 | 2.3 | 10 | 6 | 50 |

| 6 | 60 | 0.94 | 2.8 | 10 | 6 | 50 |

| 8 | 60 | 1.29 | 3.6 | 12 | 8 | 60 |

| 10 | 60 | 1.61 | 4.5 | 15 | 10 | 60 |

| 12 | 60 | 1.94 | 5.4 | 18 | 12 | 60 |

| 2 | 45 | 0.55 | 0.9 | 4 | 4 | 50 |

| 3 | 45 | 0.8 | 1.4 | 6 | 4 | 50 |

| 4 | 45 | 1.05 | 1.9 | 8 | 4 | 50 |

| 5 | 45 | 1.35 | 2.3 | 10 | 6 | 50 |

| 6 | 45 | 1.6 | 2.8 | 10 | 6 | 50 |

| 8 | 45 | 2.2 | 3.6 | 12 | 8 | 60 |

| 10 | 45 | 2.75 | 4.5 | 15 | 10 | 60 |

| 12 | 45 | 3.3 | 5.4 | 18 | 12 | 60 |

| 2 | 30 | 0.96 | 0.9 | 4 | 4 | 50 |

| 3 | 30 | 1.4 | 1.4 | 6 | 4 | 50 |

| 4 | 30 | 1.84 | 1.9 | 8 | 4 | 50 |

| 5 | 30 | 2.37 | 2.3 | 10 | 6 | 50 |

| 6 | 30 | 2.81 | 2.8 | 10 | 6 | 50 |

| 8 | 30 | 3.86 | 3.6 | 12 | 8 | 60 |

| 10 | 30 | 4.82 | 4.5 | 15 | 10 | 60 |

| 12 | 30 | 5.79 | 5.4 | 18 | 12 | 60 |

Ile-iṣẹ naa ni laini iṣelọpọ ẹrọ iṣelọpọ abẹfẹlẹ pipe lati igbaradi ohun elo aise, ṣiṣe mimu, titẹ, titẹ titẹ, lilọ, ibora ati ibora lẹhin itọju. O fojusi lori iwadi ati ĭdàsĭlẹ ti ipilẹ ohun elo, yara be, konge lara ati dada bo ti awọn ifibọ carbide NC, ati ki o nigbagbogbo mu awọn machining ṣiṣe, iṣẹ aye ati awọn miiran Ige-ini ti carbide NC awọn ifibọ. Lẹhin diẹ sii ju ọdun mẹwa ti iwadii imọ-jinlẹ ati isọdọtun, ile-iṣẹ ti ni oye nọmba kan ti awọn imọ-ẹrọ mojuto ominira, ni R&D ominira ati awọn agbara apẹrẹ, ati pe o le pese iṣelọpọ ti adani fun alabara kọọkan.