- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

HJDK650 Tungsten carbide aarin drills

Tungsten carbide aarin drills

HJDK650 Tungsten carbide aarin drills

Dara fun liluho, irin, irin alagbara, irin simẹnti, ti kii-ferrous ohun elo.

Lile HRA92.8

Ohun elo: tungsten carbide

HJDK650 jara-aarin drills

Gbólóhùn gidi:

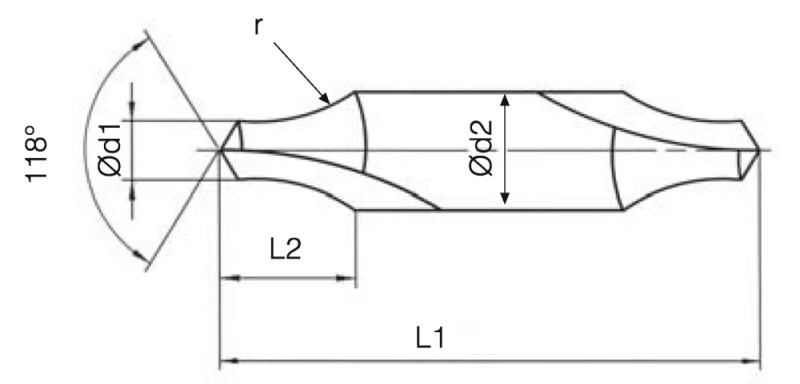

HJDK650 aarin lu mọ apapo ti o dara laarin ṣiṣan chirún ni apakan lilu ati pe ni ipin countersink. Wọn fèrè le ni kikun gba awọn eerun ati ki o ṣiṣẹ daradara lati eject awọn chips.center drills ni awọn Ige egbegbe lori mejeji opin, ati ki o ni ajija fèrè.Nipa ti o dara ni ërún ejection, iru wahala di kere bi awọn irinṣẹ adehun nitori lati ërún clogging.Considering lu. agbara, a ti gbe sẹgbẹ gigun. Siwaju sii lati san isanpada ailera ni aaye sisopọ laarin lu ati countersink, aaye asopọ ni R eyiti rediosi wa laarin ẹhin-taper ti liluho naa. Won tun ni kan jakejado ila-soke.

Awọn ẹya:

Dara fun liluho, irin, irin alagbara, irin simẹnti, ti kii-ferrous ohun elo.

Stub chisel, o tayọ agbara aarin ara ẹni.

Radial ojuami, kere Ige resistance.

Aaye chamfer, ti o ga kikọ sii oṣuwọn, ti o ga ṣiṣe.

Iwọn deede:HJDK650 Fine Powder Center Drill Series

| Nbere koodu | Iwọn opin | Igun | Gigun fèrè | O.A.L. | Shank Dia. |

| HJDK650-0102 | 1 | 60° | 1.5 | 35 | 4 |

| HJDK650-0202 | 2 | 60° | 2.5 | 50 | 5 |

| HJDK650-0252 | 2.5 | 60° | 3 1 | 60 | 6.3 |

| HJDK650-03152 | 3.15 | 60° | 3.9 | 70 | 8 |

| HJDK650-0402 | 4 | 60° | 5 | 80 | 10 |

| HJDK650-0502 | 5 | 60° | 6.3 | 80 | 12 |

| HJDK650-0632 | 6.3 | 60° | 80 | 80 | 16 |

Iṣakojọpọ ohun elo irinṣẹ:

1.Awọn ohun-ini ti ara:

A) Lile ti o tobi ju tabi dọgba si 92.8 HRA;

B) iwuwo tobi ju tabi dogba si 14.2 g/cm³;

C) TRS tobi ju tabi dogba si 4200 N/mm²;

D) Ọfẹ ti ipo alakoso ETA;

E) Ko si ibajẹ nipasẹ awọn ohun elo miiran;

F) Porosity = A00 / B00 / C00;

G) Aṣọṣọ ati iwọn ọkà ni ibamu. Ko si iwọn ọkà ti o le jẹ tobi ju pàtó lọ.

H) Chromium carbide onidalẹkun idagbasoke ọkà nikan.

2.Gbogbo awọn irinṣẹ ti iṣelọpọ, awọn aṣọ ti a lo ni Germany, Switzerland, ohun elo ṣiṣe;

paramita isẹ́:

| paramita iṣẹ liluho aarin: | ||||||||||

| Ohun elo Iṣẹ | Iyara gige | Oṣuwọn ifunni (mm/rev) | ||||||||

| (mita/iṣẹju) | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D20 | ||

| Low carbon steel, long chip (<125HB) | 130 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.15 | 0.17 | 0.2 | 0.24 | 0.26 | 0.3 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.26 | 0.3 | 0.32 | 0.35 | 0.4 | 0.45 | ||

| Irin erogba kekere, gige kukuru, irin irọrun ( | 120 | 0.1 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.24 | 0.3 | 0.32 | 0.34 | 0.4 | 0.45 | ||

| Irin erogba giga ati irin erogba’ alabọde ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Alloy, irin, irin irin ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Alloy, irin, irin irin (35-48HRC)) | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| PH ati ferritic, irin martensitic ( | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Gray iron(<32HRC) | 140 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Alloy irin ti iṣoro ilabọde ṣisẹ, irin simẹnti nodular ( | 130 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 105 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Irin simẹnti giga giga ti a ko le fa, irin simẹnti nodular ( | 120 | 0.1 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.28 | |

| 90 | 0.16 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.29 | ||

| 60 | 0.22 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.35 | ||

| Aluminiomu alloy ti a ṣe (Si | 150 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Simẹnti aluminiomu alloy (Si | 150 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 120 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Simẹnti aluminiomu alloy (Si> 12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| 12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

Ejò, epo ejò (

Ifarabalẹ:

Rii daju pe nkan iṣẹ ati ẹrọ jẹ iduroṣinṣin ati lo dimu konge, lo awọn hydraulic chucks, didara didara collet chucks.

Rii daju pe lapapọ itọkasi ṣiṣe-jade (TIR) kere ju 0.02mm.

Ipo gige ti a ṣeduro jẹ o dara fun lilo omi soluable.

Ile-iṣẹ naa ni laini iṣelọpọ ẹrọ iṣelọpọ abẹfẹlẹ pipe lati igbaradi ohun elo aise, ṣiṣe mimu, titẹ, titẹ titẹ, lilọ, ibora ati ibora lẹhin itọju. O fojusi lori iwadi ati ĭdàsĭlẹ ti ipilẹ ohun elo, yara be, konge lara ati dada bo ti awọn ifibọ carbide NC, ati ki o nigbagbogbo mu awọn machining ṣiṣe, iṣẹ aye ati awọn miiran Ige-ini ti carbide NC awọn ifibọ. Lẹhin diẹ sii ju ọdun mẹwa ti iwadii imọ-jinlẹ ati isọdọtun, ile-iṣẹ ti ni oye nọmba kan ti awọn imọ-ẹrọ mojuto ominira, ni R&D ominira ati awọn agbara apẹrẹ, ati pe o le pese iṣelọpọ ti adani fun alabara kọọkan.