- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

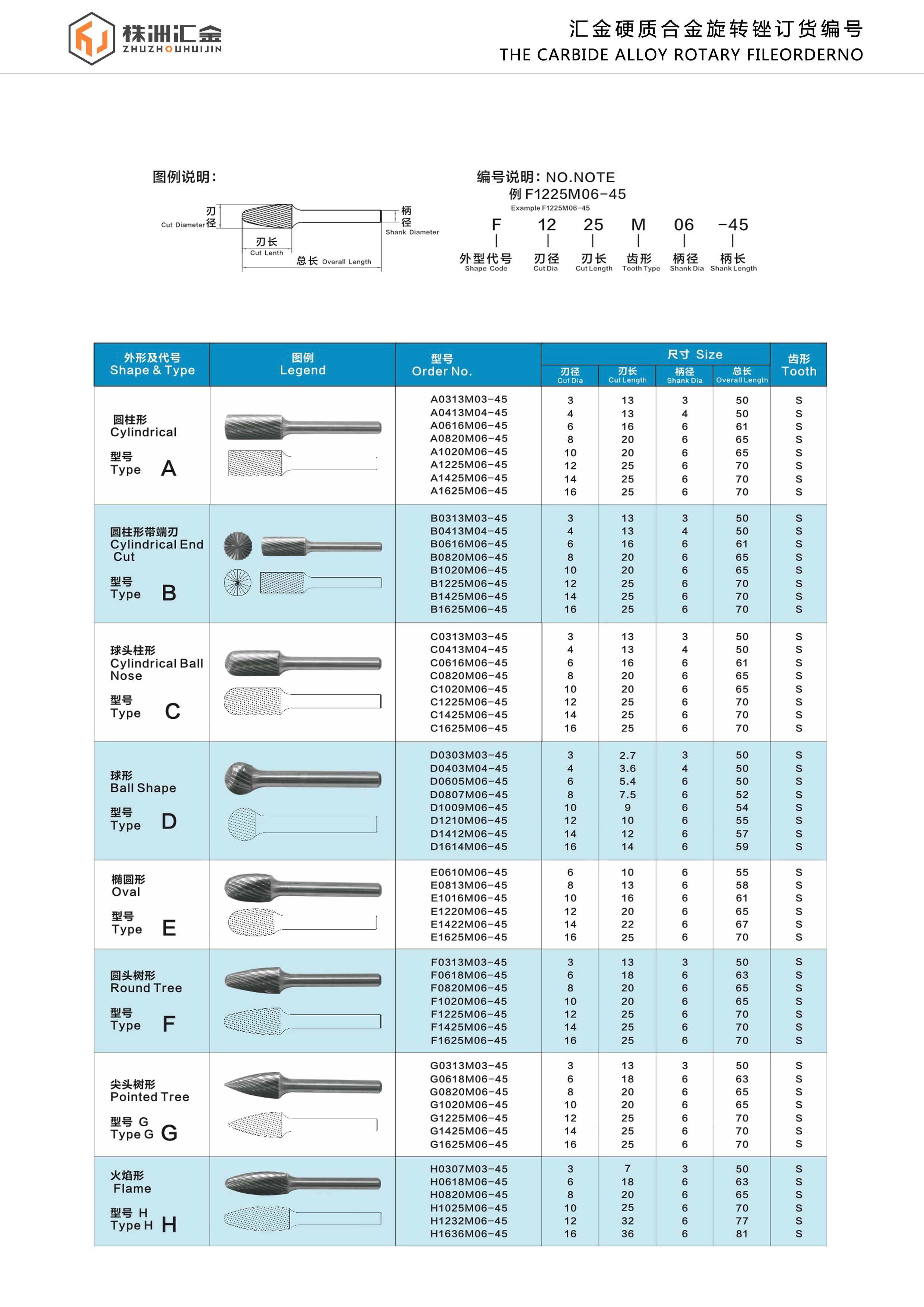

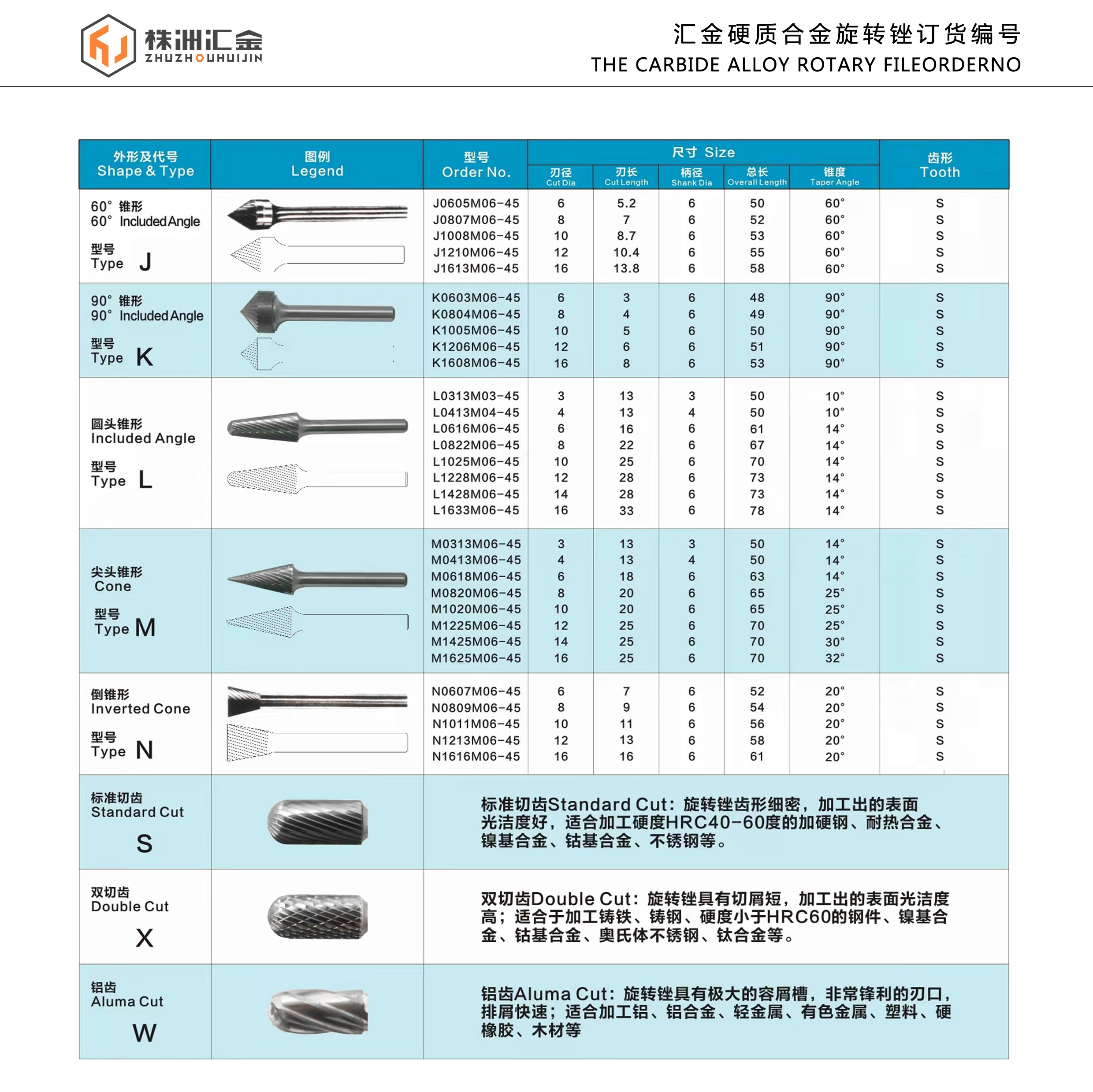

Simenti carbide rotari burrs fun metalworking

Osunwon tungsten carbide Burr Rotari faili

Osunwon tungsten irin carbide Burr Rotari faili

nikan ge & ilopo-ge

Simenti carbide rotary burrs le ṣee lo ni lilo pupọ ni irin maching, simẹnti irin, irin erogba, irin alloy, irin alagbara, irin, aluminiomu Ejò, bbl

Ohun elo: O le ṣe atunṣe irin simẹnti, irin simẹnti, irin carbon, irin alloy, irin alagbara, irin, Ejò, aluminiomu ati awọn irin miiran, ati okuta didan, jade, egungun ati awọn miiran ti kii ṣe irin. Awọn hardnes ti n ṣiṣẹ

ọja Apejuwe

Awọn carbide alloy Rotari faili ni awọn fitter ati m laala ká indispensable to ti ni ilọsiwaju ọpa, awọn oniwe-ti iwa ni aropo fun awọn igbanu mu kekere lilọ kẹkẹ ati awọn ti kii-eruku idoti, awọn iṣẹ aye jẹ dogba si orisirisi awọn ọgọrun igbanu mu kekere lilọ kẹkẹ, awọn processing ṣiṣe. imudara loke 5 igba, ni isalẹ abrasive machning ìyí ti líle HRC70 kọọkan irin ati awọn nonmetallic meterial, lilọ dada roughness le de ọdọ Ral.6, wewewe grasps, lo lati wa ni rọrun, ailewu gbẹkẹle, din ku arduous Afowoyi laala gidigidi, din iye owo ti iṣelọpọ.

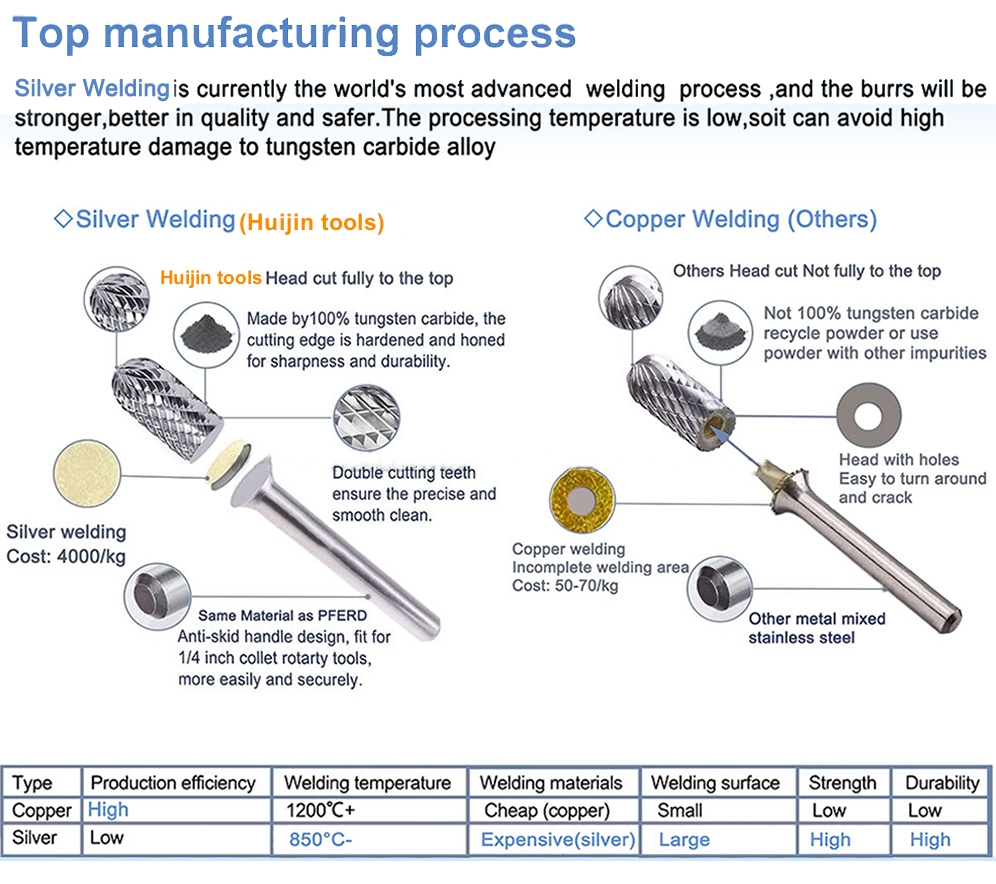

Ohun elo: 100% ti awọn ohun elo aise.

Ifarada: iṣakoso iwọn ifarada ti o muna, eyiti o le de ọdọ +/- 0.01mm;

Awọn ipele: oriṣiriṣi fun yiyan: YG6, YG8, YG8C, YG11C, YG15C ati bẹbẹ lọ.

Awọn oriṣi: boṣewa, conical, parabolic, ballistic

Iṣẹ ṣiṣe ti ara: lile giga ati lile ipa, ẹrọ ti o dara pupọ & iduroṣinṣin kemikali.

ọja iru / iwọn

ọja elo

Faili iyipo carbide ti simenti jẹ lilo pupọ ni ẹrọ, ọkọ ayọkẹlẹ, ọkọ oju omi, ile-iṣẹ kemikali, gbigbe iṣẹ ọwọ ati awọn apa ile-iṣẹ miiran, pẹlu ipa iyalẹnu. Awọn lilo akọkọ rẹ ni:

-- Fine machining orisirisi irin m cavities.-- Gbogbo iru irin, ti kii-irin gbígbẹ, ati gbígbẹ ti iṣẹ ọwọ ebun.

--Nọ filasi, burr ati weld ti simẹnti, forgings ati weldments

--Chamfering, yikaka ati iṣelọpọ yara ti ọpọlọpọ awọn ẹya ẹrọ, mimọ ti awọn oniho, ati ipari ti awọn aaye inu iho ti awọn ẹya ẹrọ

-- Polishing ti impeller olusare.

Iṣakoso didara:

1.Gbogbo awọn ohun elo aise ni idanwo ni awọn ofin ti iwuwo, lile ati TRS ṣaaju lilo

2.Every nkan ti ọja lọ nipasẹ ni-ilana ati ik ayewo

3.Every ipele ti ọja le wa ni itopase

Ilana iṣelọpọ ati ipari ti carbide cemented

Irin W\C Powder:Iyẹfun tungsten mimọ ti o ga julọ ni a lo bi ohun elo aise.

Adalu igbaradi:Awọn sẹsẹ rogodo ọlọ makesthe lulú eroja homogenize.The dada agbegbe ti awọn lulú ti wa ni pọ ati awọn patiku dada ti wa ni pọ.Can mu ati ki o se igbelaruge sintering.

Gbigbe sokiri slurry:Awọn igbaradi ti awọn apopọ ti wa ni lilo ni agbegbe ti o ni pipade.High ti nw nitrogen Idaabobo, munadoko idinku ti igbaradi.Ni awọn ilana, awọn adalu le mu atẹgun, ati ki o le.Ensure awọn ti nw ti awọn ohun elo ati ki o dena material.The idọti.

Iṣatunṣe funmorawon:Lilo awọn ọna ti aimi titẹ siseto, munadoko du.Absolute bomole ti abawọn, ga density.ati paapa.

Degumming ati ami-sisun ologbele-iyẹwo processing

Igbale kekere titẹ sintering:thermostatic sintering Iwọn titẹ agbara ti o pọju le de ọdọ 100 kg. Iyọkuro iho ti o ku ninu alloy ti wa ni minimized.Ni afikun, o jẹ pupọ compactand good.Degree, ga agbara alloy blank.Iṣakoso ilọsiwaju, Eto iwọn otutu le dinku awo-ara ti o lagbara. O ṣeeṣe ti iyipada didara waye.

Ologbele-pari gbigbe, carbide òfo awọn ọja

Ọjọgbọn konge machining

Nibẹ ni o wa ọpọlọpọ awọn iru ti machining ọna fun carbide konge machining. Bii EDM, gige okun waya lọra, milling CNC, CNC lathe processing, ati bẹbẹ lọ.

Kompu waeyikeyi jẹ olupese ọjọgbọn ti simenti carbide ti n ṣepọ iṣelọpọ ati ẹrọ ṣiṣe deede. Ile-iṣẹ naa ti ni ilọsiwaju iṣelọpọ ati ohun elo iṣelọpọ bii titan ati ile-iṣẹ iṣelọpọ agbo-igi, ile-iṣẹ machining marun-axis, ile-iṣẹ inaro inaro mẹrin, CNC petele boring ati ẹrọ milling, liluho iho jinlẹ, alaidun ati honing, ileru isunmọ igbale, okun waya gige, bbl Ṣiṣe agbara atilẹyin. O ni agbara ti o lagbara pupọ ninu ẹrọ titọ ti carbide cemented, ati pe o ni ipese pẹlu ọpọlọpọ awọn ohun elo ẹrọ ilọsiwaju, eyiti o dara fun ẹrọ ti ọpọlọpọ awọn iwọn to gaju, awọn ohun elo pataki, apẹrẹ inu eccentric, awọn igbonwo, ati awọn ẹya geometric eka.

To ti ni ilọsiwaju onínọmbà ati igbeyewo ẹrọ

Huijin ti ni ipese pẹlu itupalẹ ilọsiwaju ati ohun elo idanwo, gẹgẹbi: olutupalẹ sulfur carbon, tester TRS, microscope metallographic, tester coercivity, cobalt magnetic tester, Rockwell hardness tester, Vickers hardness tester, drop tester, micrometer, roundness tester, ultrasonic scanner, etc. ., Ilana kọọkan le ṣe abojuto ni imunadoko lati rii daju iwọn oṣuwọn ti awọn ọja.

Ayẹwo ohun elo aise: lo oluyẹwo carbon-sulfur lati pinnu akojọpọ kemikali ti tungsten carbide lulú jẹ oṣiṣẹ.

Lẹhin sisọpọ, lo ohun elo lati ṣe idanwo ohun elo naa: idanwo TRS, microstructure, akoonu cobalt, líle ti ohun elo, ọpa carbide cemented ati idanwo ju silẹ lati rii daju pe ko si abawọn agbedemeji ninu ohun elo, simenti carbide mold sofo, ṣafikun ultrasonic scanner lati yago fun iyanrin Iho inu awọn òfo.

Ayẹwo ohun elo afọwọṣe lẹhin sisọ: Ayẹwo wiwo ti awọn abawọn ohun elo nipasẹ awọn oṣiṣẹ ti oye, pẹlu carburization ati decarburization, awọn ihò iyanrin dada, awọn dojuijako kekere.

Ayẹwo onisẹpo lẹhin sisọ: Ṣayẹwo awọn iwọn pẹlu micrometer kan, ati fun awọn ọpa carbide, ṣafikun idanwo iyipo.

Awọn ọna Ifijiṣẹ / Iṣakojọpọ

-Express awọn ile-iṣẹ: DHL, FedEx, TNT, UPS, bbl

- Awọn ọkọ ofurufu.

-Okun sowo

A. Iṣakojọpọ Standard

- Awọn apoti ṣiṣu pẹlu foomu inu ati paali ita.

-Paper apoti pẹlu foomu inu ati paali ita.

- Awọn apoti inu / ohun elo iṣakojọpọ inu ati apoti itẹnu ni ita (fun ọja eru)

Ile-iṣẹ naa ni laini iṣelọpọ ẹrọ iṣelọpọ abẹfẹlẹ pipe lati igbaradi ohun elo aise, ṣiṣe mimu, titẹ, titẹ titẹ, lilọ, ibora ati ibora lẹhin itọju. O fojusi lori iwadi ati ĭdàsĭlẹ ti ipilẹ ohun elo, yara be, konge lara ati dada bo ti awọn ifibọ carbide NC, ati ki o nigbagbogbo mu awọn machining ṣiṣe, iṣẹ aye ati awọn miiran Ige-ini ti carbide NC awọn ifibọ. Lẹhin diẹ sii ju ọdun mẹwa ti iwadii imọ-jinlẹ ati isọdọtun, ile-iṣẹ ti ni oye nọmba kan ti awọn imọ-ẹrọ mojuto ominira, ni R&D ominira ati awọn agbara apẹrẹ, ati pe o le pese iṣelọpọ ti adani fun alabara kọọkan.