- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

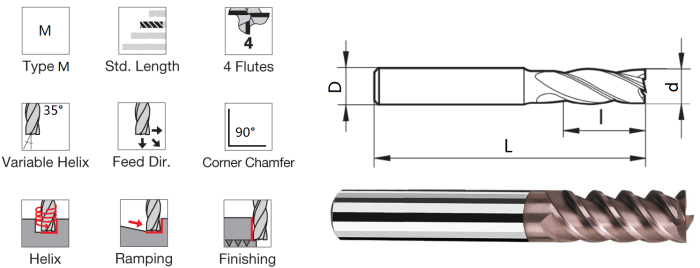

I-F4 Isiphelo sokusila somatshini oqhelekileyo wensimbi engenasici

HJS600 series - Jikelele Machining of Stainless Steel

HJS600 series - Jikelele Machining of Stainless Steel

Ifanele ukwenziwa kwentsimbi jikelele (

I-Universal Performance Coating ye-AlCrSiN

F4

Ingxelo yenyani:

Insimbi engenasici iqulethe i-Si, i-Ni kunye nezinye iintsimbi eziphikisayo, ngoko ke ukuqina kunye nokomelela kuhle kakhulu. Xa sisenza iiendmill zentsimbi estainless, sisebenzisa i- micro tungsten carbide, kunye nokwaleka okukhethekileyo , ukuze kuphuculwe ngokufanelekileyo ukusebenza kweemveliso. Olu chungechunge lwee-endmills luye lwenziwa kwi-Iphone 5 ye-304 yesakhiwo sensimbi engenasici, kwaye iphumelele iziphumo ezilungileyo, kwaye iphumelele indumiso ephezulu evela kwi-FOXCNN kunye ne-MiYa.

Iimbonakalo:

Ifanele ukwenziwa komatshini jikelele wensimbi engenasici (

Uyilo olukhethekileyo lwe-edge, ukusombulula ngempumelelo iimvuthuluka.

Ukupholisa amanzi, ukupholisa ioli yeyona ndlela ingcono yokupholisa.

Ubungakanani obuqhelekileyo:

| Ikhowudi yokuodola | Ngaphandle Ububanzi | Ubude beFlute | Ubude bubonke | Shank Diameter |

| (d) | (l) | (L) | (D) | |

| HJS600-4F-D010-L050 | 1.0 | 3.0 | 50 | 4 |

| HJS600-4F-D015-L050 | 1.5 | 4.5 | 50 | 4 |

| HJS600-4F-D020-L050 | 2.0 | 6.0 | 50 | 4 |

| HJS600-4F-D025-L050 | 2.5 | 7.0 | 50 | 4 |

| HJS600-4F-D030-L050 | 3.0 | 8.0 | 50 | 4 |

| HJS600-4F-D035-L050 | 3.5 | 10.0 | 50 | 4 |

| HJS600-4F-D040-L050 | 4.0 | 11.0 | 50 | 4 |

| HJS600-4F-D050-L050 | 5.0 | 13.0 | 50 | 6 |

| HJS600-4F-D060-L050 | 6.0 | 16.0 | 50 | 6 |

| HJS600-4F-D070-L060 | 7.0 | 17.0 | 60 | 8 |

| HJS600-4F-D080-L060 | 8.0 | 20.0 | 60 | 8 |

| HJS600-4F-D090-L075 | 9.0 | 25.0 | 75 | 10 |

| HJS600-4F-D100-L075 | 10.0 | 25.0 | 75 | 10 |

| HJS600-4F-D110-L075 | 11.0 | 28.0 | 75 | 12 |

| HJS600-4F-D120-L075 | 12.0 | 30.0 | 75 | 12 |

| HJS600-4F-D140-L080 | 14.0 | 35.0 | 80 | 14 |

| HJS600-4F-D160-L100 | 16.0 | 45.0 | 100 | 16 |

| HJS600-4F-D180-L100 | 18.0 | 48.0 | 100 | 18 |

| HJS600-4F-D200-L100 | 20.0 | 50.0 | 100 | 20 |

Ukuqulunqwa kwezixhobo zesixhobo:

1. IiPropati zoMzi:

a. Ubunzima obukhulu okanye obulingana no-92.8 HRA;

b. Uxinzelelo olukhulu kuno okanye olulingana no 14.2g/cm³;

c. TRS inkulu kuno okanye ilingana no 4200 N/mm²;

d. Isimahla kwimeko yesigaba se-ETA;

e. Akukho ungcoliseko ngezinye izinto;

f. Porosity = A00/ B00 / C00 ;

g. Ubungakanani obufanayo kunye nobukhulu obufanayo. Akukho bungakanani benkozo bunokuba bukhulu kunoko buchaziwe.

h. I-Chromium carbide grain growth inhibitor kuphela.

2. Zonke izixhobo zemveliso, iingubo zisetyenziswa eJamani, eSwitzerland, izixhobo zokulungisa;

Ukwaleka:

I-Universal Performance Coating ye-AlCrSiN

Iimpawu kunye noMsebenzi

1, Ukwanda kwemveliso ngenxa yesantya esiphakamileyo sokusika kunye nokutya kosetyenziso kuluhlu olubanzi lwezinto.

2, Uyilo olulodwa lolwakhiwo luzisa ibhalansi elungileyo phakathi kokuqina, uzinzo lwe-thermo-shock kunye noxinzelelo olushiyekileyo.

Ukwaleka:

1, i-AlCrSiN yokuSebenza okuPhakamileyo:

2, Uyilo olulodwa lolwakhiwo luzisa ibhalansi elungileyo phakathi kokuqina, uzinzo lwe-thermo-shock kunye noxinzelelo olushiyekileyo.

Ipharamitha yokusebenza:

| HJS600 S4 For Stainless Steels-Side Milling | ||||||||||||||

| Amabanga | Ubume besixhobo | Umsebenzi | Ukusika ubunzulu | VC m/min | Isixhobo Ububanzi | 1 | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| S4 | Izinto eziphathekayo | (mm) | (mm) | |||||||||||

| DLTUS600 | Isikwere, | Yenziwe ngentsimbi eshayinayo | ap≤1D | 100 | Isantya | 25000 | 15900 | 7960 | 5300 | 3980 | 3180 | 2650 | 1990 | 1590 |

| Ikona irediyasi | (80-120) | (min-1) | ||||||||||||

| ae≤0.1D | Isantya sokutya | 700 | 635 | 700 | 680 | 730 | 660 | 600 | 490 | 460 | ||||

| (mm/min) | ||||||||||||||

Ingqalelo:

Qinisekisa ukuba umsebenzi kunye nomatshini uzinzile kwaye usebenzise isibambi esichanekileyo.

Nceda uhlengahlengise isantya, ukondla kunye nokusika ubunzulu ngokweemeko zokusika.

I-conditiongs yokusila yeyokusila isiphelo apho ubude besixhobo sokuxhoma bungaphantsi kwe-4 * D (i-mill dia). Xa ubude besixhobo sokuxhoma bubude, nceda uhlengahlengise isantya, ukondla kunye nobunzulu bokusika.

Inkampani inomgca opheleleyo wenkqubo yokuvelisa izixhobo ze-blade ukusuka kumgubo wokulungiselela izinto ezikrwada, ukwenza umngundo, ukucinezela, ukucofa uxinzelelo, ukugaya, ukugquma kunye nokugquma emva konyango. Ijolise kuphando kunye nokuveliswa kwezinto ezisisiseko, isakhiwo se-groove, ukuchaneka ukubunjwa kunye nokugubungela umphezulu we-carbide NC inserts, kwaye rhoqo iphucula ukusebenza kakuhle komatshini, ubomi benkonzo kunye nezinye iipropati zokusika ze-carbide NC inserts. Emva kweminyaka engaphezu kweshumi yophando lwezenzululwazi kunye nokusungula izinto ezintsha, inkampani iye yakwazi ubuninzi betekhnoloji engundoqo ezimeleyo, ine-R&D ezimeleyo kunye nobuchule bokuyila, kwaye inokubonelela ngemveliso elungiselelwe umthengi ngamnye.