Uhlalutyo lokuqulunqwa kokufakwa kwe-carbide enesamente

Njengazo zonke iimveliso ezenziwe ngumntu, ukuveliswa kweentsimbi ezinqabileyo zokusika kufuneka ziqale zisombulule ingxaki yemathiriyeli ekrwada, oko kukuthi, ukumisela ukubunjwa kunye nefomula yezixhobo ze-blade. Uninzi lweentsimbi zanamhlanje zenziwe nge-cemented carbide, eyona nto yenziwe yi-tungsten carbide (WC) kunye ne-cobalt (Co). I-WC yi-particle enzima kwi-blade, kwaye i-Co ingasetyenziswa njenge-binder ukubumba i-blade.

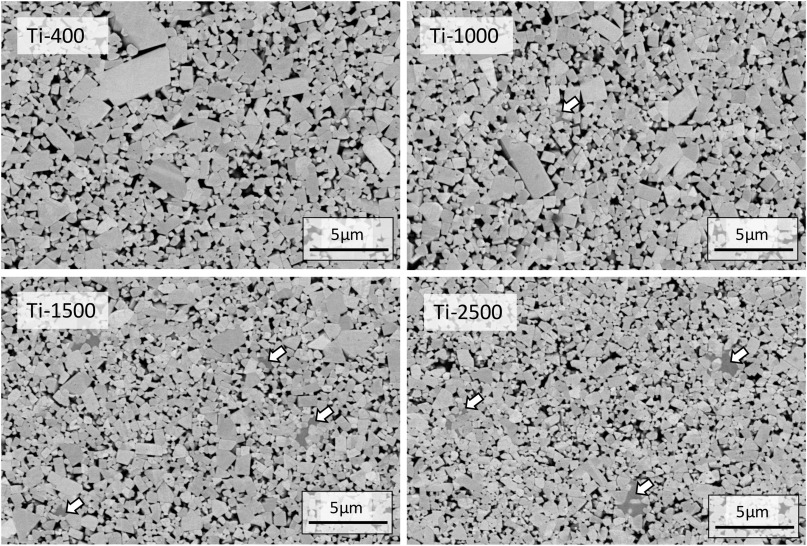

Indlela elula yokutshintsha iipropati ze-carbide ene-cemented kukutshintsha ubungakanani beenkozo ze-WC ezisetyenzisiweyo. Ubungakanani be-particle enkulu (3-5 μ m) Ubunzima bezinto ze-carbide ze-cemented ezilungiselelwe ngamaqhekeza e-WC nge-C% iphantsi kwaye kulula ukuyinxiba; Ubungakanani bamasuntswana amancinane (< 1 μ m) Amasuntswana e-WC anokuvelisa imathiriyeli ye-alloy eqinile enobulukhuni obuphezulu, ukuxhathisa okungcono kokunxiba, kodwa kunye nokuqina okukhulu. Xa kusenziwa izinto zetsimbi ezinobunzima obuphezulu kakhulu, ukusetyenziswa kweenkozo ezicolekileyo ezifakwe kwi-carbide kunokufikelela kwiziphumo ezifanelekileyo zomatshini. Kwelinye icala, isixhobo se-carbide esiziinkozo esirhabaxa sinokusebenza ngcono ekusikeni okwethutyana okanye obunye ubuchwephesha obufuna ukuqina okuphezulu kwesixhobo.

Enye indlela yokulawula iimpawu zokufakwa kwe-carbide ene-cemented kukutshintsha umlinganiselo we-WC kumxholo we-Co. Xa kuthelekiswa neWC, ubunzima be-Co buphantsi kakhulu, kodwa ukuqina kungcono. Ngoko ke, ukunciphisa umxholo we-Co kuya kubangela i-blade ephezulu yobunzima. Ngokuqinisekileyo, oku kwakhona kuphakamisa ingxaki yokulinganisela okupheleleyo - ii-blades ezinobunzima obuphezulu zinokuxhathisa ukunxiba, kodwa ukunyanzeliswa kwazo kukhulu. Ngokohlobo oluthile lokusetyenzwa, ukukhetha ubungakanani bengqolowa obufanelekileyo beWC kunye neCo content ratio kufuna ulwazi olufanelekileyo lwezenzululwazi kunye namava okusebenza atyebileyo.

Ngokusebenzisa itekhnoloji yemathiriyeli yegradient, ukulungelelana phakathi kokuqina kunye nokuqina kweblade kunokuthintelwa kwinqanaba elithile. Le teknoloji, eye yasetyenziswa ngokubanzi ngabavelisi bezixhobo eziphambili zehlabathi, iquka ukusetyenziswa komlinganiselo ophezulu weCo content kumaleko wangaphandle weblade kunomaleko ongaphakathi. Ngokukodwa, umaleko wangaphandle we-blade (ubukhulu be-15-25 μ m) Yandisa umxholo we-Co ukubonelela umsebenzi ofana ne "buffer zone", ukwenzela ukuba i-blade inokumelana nempembelelo ethile ngaphandle kokuqhekeka. Oku kwenza ukuba umzimba wesixhobo seblade ufumane iipropathi ezahlukeneyo ezibalaseleyo ezinokufezekiswa kuphela ngokusebenzisa i-carbide enesamente enamandla aphezulu.

Nje ukuba ubungakanani bamasuntswana, ukubunjwa kunye nezinye iiparitha zobugcisa bezinto ezikrwada zichongiwe, inkqubo yokwenziwa kwangempela yokufakwa kokusika inokuqaliswa. Okokuqala, faka i-tungsten powder ehambelanayo, i-carbon powder kunye ne-cobalt powder kwi-mill emalunga nobukhulu obufana nomatshini wokuhlamba, ugaye umgubo kwi-particle efunekayo, kwaye udibanise zonke iintlobo zezinto ngokulinganayo. Ngethuba lenkqubo yokugaya, utywala kunye namanzi zongezwa ukulungiselela udaka olumnyama olumnyama. Emva koko i-slurry ifakwe kwi-cyclone dryer, kwaye ulwelo olukwi-slurry luba ngumphunga ukuze lufumane umgubo we-lumpy kwaye lugcinwe.

Kwinkqubo elandelayo yokulungiselela, iprototype ye-blade inokufumaneka. Okokuqala, i-powder elungiselelwe ixutywe ne-polyethylene glycol (PEG). Njenge-plasticizer, i-PEG inokubopha okwethutyana umgubo kunye njengentlama. Izinto ke zicinezelwe kwimilo yeblade kwidayisi. Ngokweendlela ezahlukeneyo zokucinezela iblade, ucinezelo lwe-axis enye inokusetyenziselwa ukucinezela, okanye ucinezele i-multi axis ingasetyenziselwa ukucinezela imilo yeblade kwii-engile ezahlukeneyo.

Emva kokufumana i-blank blank, ifakwa kwisithando somlilo esikhulu kwaye ifakwe kwiqondo lokushisa eliphezulu. Kwinkqubo ye-sintering, i-PEG iyancibilika kwaye ikhutshwe kumxube we-billet, ishiya i-carbide blade ene-semi-finished cemented blade. Xa i-PEG inyibilika, iblade iyacutheka ukuya * kubungakanani bayo bokugqibela. Eli nyathelo lenkqubo lifuna ukubala kwezibalo ezichanekileyo, kuba ukucutheka kweblade kuyahluka ngokwezinto ezahlukeneyo zokuqamba kunye nolungelelwaniso, kunye nokunyamezelana komgangatho wemveliso egqityiweyo kufuneka ilawulwe ngaphakathi kweemicrons ezininzi.

Ixesha lokuphumla: 2023-01-15