- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

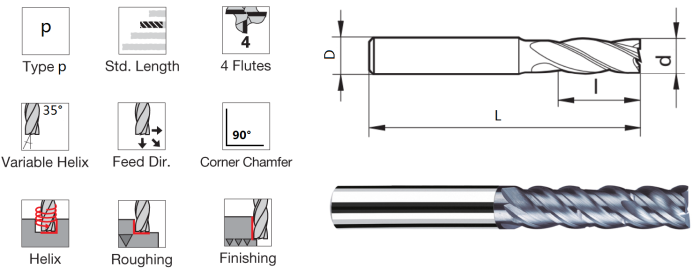

F4 F2 Qattiqlashtirilgan po'lat uchun oxirgi tegirmon (48-55 HRC)

HJMJ550 seriyali - Qattiqlashtirilgan po'lat uchun oxirgi tegirmon (48-55 HRC)

Qattiqlashtirilgan po'latlar uchun HJMJ550 so'nggi tegirmon (48-55 HRC)

qo'llanilishi: Qattiqlashtirilgan po'latlar uchun (48-55 HRC) pardozlash.

Universal yuqori samarali qoplama AlCrSiN

F4 F2

Literal ibora:

Kalıp uchun uch tegirmon keng qo'llaniladi, pnevmatik yoki elektr asboblarda o'rnatilishi va ishlatilishi mumkin, silliqlash g'ildiragidan ko'ra ishlab chiqarish samaradorligi va chidamliligi va fayl sonini oshiradi.

Xususiyatlari:

1. Yuqori qattiqlik, yuqori qattiqlikdagi matritsa materiallari, maxsus burchak dizayni va chekka ishlov berish, qattiqlashtirilgan po'latlar uchun maxsus.

2.Qattiqlashtirilgan po'latlarni (48-60 HRC) tugatish uchun.

3.Havo yoki yog 'tumanini sovutishdan foydalanish tavsiya etiladi.

Oddiy o'lcham:

1.4 ta nayli frezalar

| Tashqi diametri | Fleyta uzunligi | Umumiy uzunlik | Sham diametri | |

| (d) | (l) | (L) | (D) | |

| HJMJ550-4F-D010-L050 | 1.0 | 3.0 | 50 | 4 |

| HJMJ550-4F-D015-L050 | 1.5 | 4.5 | 50 | 4 |

| HJMJ550-4F-D020-L050 | 2.0 | 6.0 | 50 | 4 |

| HJMJ550-4F-D025-L050 | 2.5 | 7.0 | 50 | 4 |

| HJMJ550-4F-D030-L050 | 3.0 | 8.0 | 50 | 4 |

| HJMJ550-4F-D035-L050 | 3.5 | 10.0 | 50 | 4 |

| HJMJ550-4F-D040-L050 | 4.0 | 11.0 | 50 | 4 |

| HJMJ550-4F-D050-L050 | 5.0 | 13.0 | 50 | 6 |

| HJMJ550-4F-D060-L050 | 6.0 | 16.0 | 50 | 6 |

| HJMJ550-4F-D070-L060 | 7.0 | 17.0 | 60 | 8 |

| HJMJ550-4F-D080-L060 | 8.0 | 20.0 | 60 | 8 |

| HJMJ550-4F-D090-L075 | 9.0 | 25.0 | 75 | 10 |

| HJMJ550-4F-D100-L075 | 10.0 | 25.0 | 75 | 10 |

| HJMJ550-4F-D110-L075 | 11.0 | 28.0 | 75 | 12 |

| HJMJ550-4F-D120-L075 | 12.0 | 30.0 | 75 | 12 |

| HJMJ550-4F-D140-L080 | 14.0 | 35.0 | 80 | 14 |

| HJMJ550-4F-D160-L100 | 16.0 | 45.0 | 100 | 16 |

| HJMJ550-4F-D180-L100 | 18.0 | 48.0 | 100 | 18 |

| HJMJ550-4F-D200-L100 | 20.0 | 50.0 | 100 | 20 |

2. 2 Flute Corner Radius End Mills

| Tashqi diametri | R | Fleyta uzunligi | Umumiy uzunlik | Sham diametri | |

| (d) | (l) | (L) | (D) | ||

| HJMJ550-2F-010-02 | 1 | 0.2 | 2 | 50 | 4 |

| HJMJ550-2F-015-02 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ550-2F-015-03 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ550-2F-020-02 | 2 | 0.2 | 4 | 50 | 4 |

| HJMJ550-2F-020-05 | 2 | 0.5 | 4 | 50 | 4 |

| HJMJ550-2F-025-02 | 2.5 | 0.2 | 5 | 50 | 4 |

| HJMJ550-2F-025-05 | 2.5 | 0.5 | 5 | 50 | 4 |

| HJMJ550-2F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ550-2F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ550-2F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ550-2F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ550-2F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ550-2F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ550-2F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ550-2F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ550-2F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ550-2F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ550-2F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ550-2F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ550-2F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ550-2F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ550-2F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ550-2F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ550-2F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ550-2F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ550-2F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ550-2F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ550-2F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ550-2F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ550-2F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ550-2F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ550-2F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ550-2F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ550-2F-120-20 | 12 | 20 | 24 | 75 | 12 |

| HJMJ550-2F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ550-2F-120-30 | 12 | 3 | 24 | 75 | 12 |

3.4 Fleyta burchakli radiusli frezalar

| Tashqi diametri | R | Fleyta uzunligi | Umumiy uzunlik | Sham diametri | |

| (d) | (l) | (L) | (D) | ||

| HJMJ550-4F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ550-4F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ550-4F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ550-4F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ550-4F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ550-4F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ550-4F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ550-4F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ550-4F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ550-4F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ550-4F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ550-4F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ550-4F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ550-4F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ550-4F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ550-4F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ550-4F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ550-4F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ550-4F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ550-4F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ550-4F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ550-4F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ550-4F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ550-4F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ550-4F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ550-4F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ550-4F-120-20 | 12 | 2 | 24 | 75 | 12 |

| HJMJ550-4F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ550-4F-120-30 | 12 | 3 | 24 | 75 | 12 |

Asbob materialining tarkibi

Universal yuqori samarali qoplama AlCrSiN

Xususiyatlari va funktsiyasi

1、Keyinchalik yuqori kesish tezligi va materiallarning keng assortimentida qo'llanilishi uchun ozuqa tufayli mahsuldorlikni oshirish.Unumdorlikni sezilarli darajada oshirish.

2, Strukturaning alohida dizayni qattiqlik, termo-shok barqarorligi va qoldiq stress o'rtasida yaxshi muvozanatni ta'minlaydi.

Operatsion parametri:

| HJMJ550 End mill for die Operation parameter: | |||||||||||||

| HJMJ550-S2 For Alloy Steel,Hardened Steel-Side Milling | |||||||||||||

| Baholar | Asbob shakli | Ish qismi materiali | Kesish chuqurligi (mm) | VC | Asbob diametri | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| S2 | m/min | (mm) | |||||||||||

| HJMJ550 | Kvadrat, burchak radiusi | Qotishma po'lat po'lat po'lat | ap≤1D | 120 | Tezlik | 19100 | 9550 | 6730 | 4780 | 3820 | 3190 | 2390 | 1910 |

| HRC55 | (min-1) | ||||||||||||

| ae≤0.05D | Tasma tezligi | 380 | 380 | 380 | 380 | 370 | 360 | 310 | 290 | ||||

| (mm/min) | |||||||||||||

Diqqat:

Ish qismi va mashina barqaror ekanligiga ishonch hosil qiling va nozik ushlagichdan foydalaning.

Iltimos, tezlikni, besleme va kesish chuqurligini haqiqiy kesish shartlariga muvofiq sozlang.

Frezeleme shartlari asbobning osib qo'yilishi uzunligi 4*D (tegirmon diametri) dan kam bo'lgan frezalash uchun mo'ljallangan. Asbobning haddan tashqari uzunligi uzunroq bo'lsa, tezlikni, besleme va kesish chuqurligini sozlang.

Kompaniyada kukunli xom ashyoni tayyorlash, qolip tayyorlash, presslash, bosimli sinterlash, silliqlash, qoplama va qoplamadan keyingi ishlov berishdan to'liq pichoq ishlab chiqarish texnologik uskunalari ishlab chiqarish liniyasi mavjud. U asosiy materialni, yiv tuzilishini, karbid bosimining ko'tarilishi qo'shimchalarini aniq shakllantirish va sirt qoplamasini tadqiq qilish va innovatsiyalarga qaratadi va karbid bosimining ko'tarilishi qo'shimchalarining ishlov berish samaradorligini, xizmat muddatini va boshqa kesish xususiyatlarini doimiy ravishda yaxshilaydi. O'n yildan ortiq ilmiy tadqiqotlar va innovatsiyalardan so'ng kompaniya bir qator mustaqil asosiy texnologiyalarni o'zlashtirdi, mustaqil Ar-ge va dizayn imkoniyatlariga ega va har bir mijoz uchun moslashtirilgan ishlab chiqarishni ta'minlay oladi.