- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

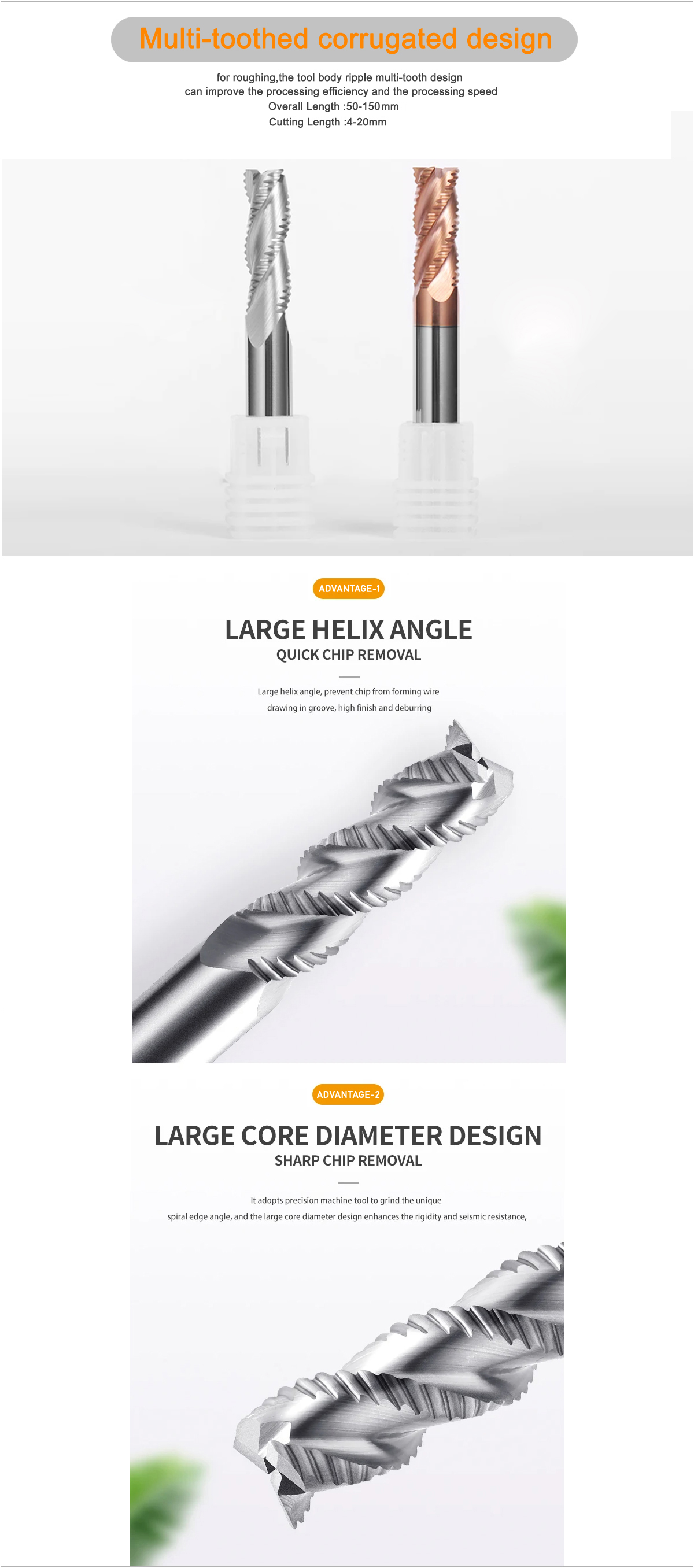

4 flutes roughing end mill for steels & Aluminum

Roughing Carbide End Mill for steel

HJPR55/65 series - Roughing Application

Solide Carbide Thread Milling Cutter

good performance

Roughing End Mill Cutter for Metal Steel

Product Description:

We make this carbide End mill for rough machining which require large amount of cutting. It can works under high speed cutting and has very good capacity of chip removal. It’s mainly used for common material roughing like cast iron, mould steel, steel, alloy steel.

Feature

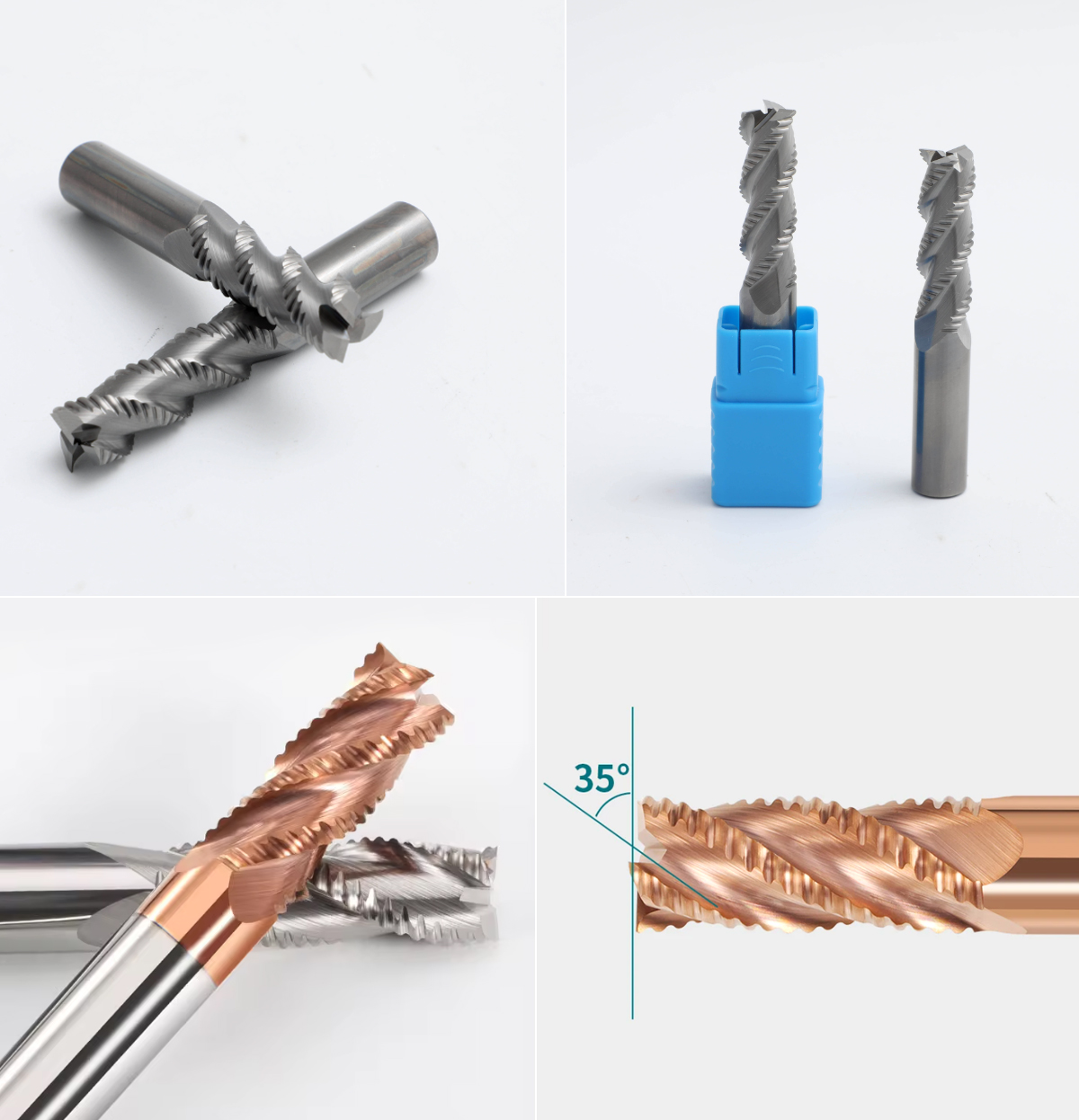

1.First-class precision machine tools are used to grind out the edge angle, large core diameter design to enhance rigidity and vibration resistance, large chip space is not easy to accumulate chips, not easy to collapse the knife, sharp and wear-resistant, smooth cutting, improve cutting efficiency.

2.Wave edge design, large chip discharge, metal cutting more smoothly large feed, large tool travel, increase production efficiency.

3.The use of particle tungsten steel base material has high wear resistance and strength, reducing the number of tool changes, increasing the machine cranking rate and improving work efficiency.

| Product name | Roughing End Mill |

| Material | Tungsten carbide |

| Model | Standard |

| Flutes | 3f/4f flutes |

| Coating | AlTiN, TiAIN,TiSiN,nACo,etc |

| HRC | 55/60/65 |

| Shank diameter | 4-20mm |

| whole length | 50-150mm |

| Helix angle | 35/45 degree |

| Application | for common material roughing like cast iron, mould steel, steel, alloy steel. |

| Machine type | CNC Milling Machine, Engraving machine,High speed machine,etc |

Our advantages:

Professional team for production: Have more than 10 years experience for production on carbide filed.

Fast delivery based on high production capability.

Strict quality control system: Ensure our product in good and stable quality.

Rich experience on customized products.

Technical support: Help you get the best solution.

Professional Carbide End Mill Manufacture

Size (standard & non-standard)

Standard:

our standard carbide milling cutters cover the diameter range from 4mm to 16mm meeting the international manufacturing management and quality standards

Non-Standard:

Our factory can manufacture the non-standard products as per the technology drawing or samples.

Regular size:

Specification Mill Diameter(mm) LOC(mm) Shank Diameter(mm) OAL(mm) 4 10 4 50 5 15 5 50 6 15 6 50 8 20 8 60 10 25 10 75 12 30 12 75 6 15 6 100 8 20 8 100 10 25 10 100 12 30 12 100 14 35 14 100 16 40 16 100 18 40 18 100 20 40 20 100 16 40 16 150 -Express companies: DHL, FedEx, TNT, UPS, etc.

-Airlines.

-Ocean shipping

A. Standard packing

-Plastic boxes with foam inside and carton outside.

-Paper boxes with foam inside and carton outside.

-Inner boxes/packing material inside and plywood box outside (for heavy product).

Компаниядә порошок чимал әзерләү, форма ясау, басу, басым синтеринг, тарттыру, каплау һәм каплаудан соң җиһаз җитештерү линиясе бар. Ул төп материалны тикшерүгә һәм яңалыкка, трубка структурасына, карбид NC кыстыргычларының төгәл формалашуына һәм өслек каплавына игътибар итә, һәм эшкәртү эффективлыгын, хезмәт срогын һәм карбид NC кыстыргычларының бүтән кисү үзлекләрен яхшырта. Ун елдан артык фәнни тикшеренүләр һәм инновацияләрдән соң, компания берничә мөстәкыйль төп технологияне үзләштерде, бәйсез фәнни-тикшеренү һәм дизайн мөмкинлекләренә ия, һәм һәр клиент өчен махсуслаштырылган җитештерүне тәэмин итә ала.