- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

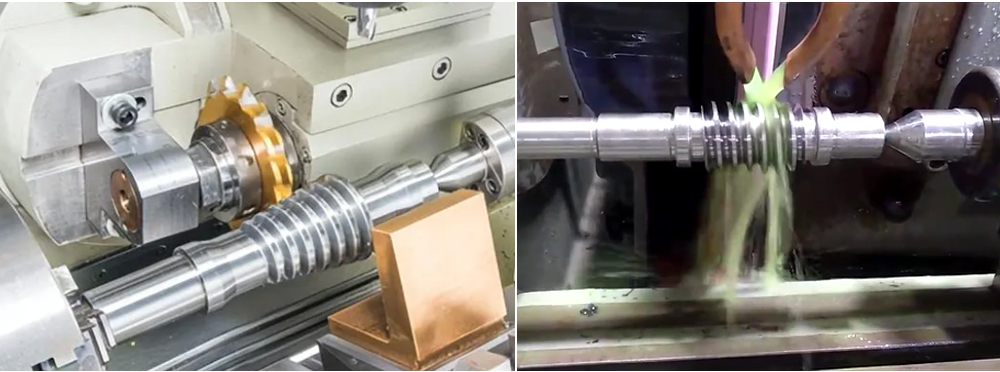

D63 Tungsten carbide worm gear milling cutter with coating

D63 Tungsten carbide worm gear milling cutter with coating

Sizes : 63*22*6.0*30T

Application : worm gear milling cutter

with coating

workpiece:BS970 EN8M,manganese steel,carbon steel

Product Description

D63 Tungsten carbide worm gear milling cutter with coating

Most of the saw cutters are made of the same kind of high speed steel, carbide and other materials. Compared

with high speed steel, the carbide has higher hardness, stronger cutting force, higher speed and feed rate, and

higher productivity.

Advantages:

1. High bending resistance makes carbide tip difficult to be broken.

2. Best material with advanced machines.

3. Deformation will not happen after long time using.

4.15 years’ experience, free consult service

5.Provide all kinds of non-standard series of products according to the users' requirements.

Tungsten carbide grade selectionK10 K20 K30 YG6A YG8 YG10X YS2T...

Tool material composition:

C) TRS greater than or equal to 3800 N/mm²;

Scope of application:

Carbide circular blade is our main product, we can produce all kinds of carbide blades with double side,

one side or with cutting teeth. They can be used for cutting paper, tobacco,

rubber, plywood, hardwood, PCB, PVC, stainless steel, high manganese steel and so on. Improved durability and

wear-life,up to 600% better than standard steels.

| External diameter(D) | Thickness(H) | Inner diameter(d) | Teet(T) |

| 25 | 0.2--5.0 | 6 8 10 | 10--58 |

| 30 | 0.2--5.0 | 6 8 10 | 10--60 |

| 32 | 0.2--6.0 | 6 8 10 12.7 | 10--60 |

| 35 | 0.2--6.0 | 8 10 12.7 | 10--60 |

| 40 | 0.2--6.0 | 8 10 12.7 | 10--80 |

| 45 | 0.2--8.0 | 10 12.7 16 | 10--80 |

| 50 | 0.2--8.0 | 10 12.7 16 | 10--100 |

| 55 | 0.2--8.0 | 12.7 16 | 24--120 |

| 60 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 63 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 70 | 0.3--8.0 | 16 22 25.4 | 28--120 |

| 75 | 0.5--8.0 | 16 22 25 4 | 30--120 |

| 80 | 0.5--8.0 | 22 25.4 | 30--128 |

| 85 | 0.5--8.0 | 22 25.4 | 30--128 |

| 90 | 0.5--8.0 | 22 25.4 | 30--160 |

| 100 | 0.5--8.0 | 22 25.4 27 | 30--160 |

| 110 | 0.8--8.0 | 22 25.4 27 32 | 30--180 |

| 120 | 1.0--10.0 | 22 25.4 27 32 | 30-240 |

| 125 | 1.0--10.0 | 22 25.4 27 | 30-240 |

| 150 | 1.0--10.0 | 22 25.4 27 32 | 40-240 |

Ang kumpanya ay may kumpletong linya ng produksyon ng kagamitan sa proseso ng pagmamanupaktura ng talim mula sa paghahanda ng hilaw na materyal ng pulbos, paggawa ng amag, pagpindot, pressure sintering, paggiling, patong at patong pagkatapos ng paggamot. Nakatuon ito sa pananaliksik at inobasyon ng base material, groove structure, precision forming at surface coating ng carbide NC inserts, at patuloy na pinapabuti ang machining efficiency, buhay ng serbisyo at iba pang cutting properties ng carbide NC inserts. Pagkatapos ng higit sa sampung taon ng siyentipikong pananaliksik at pagbabago, ang kumpanya ay nakabisado ang ilang mga independiyenteng pangunahing teknolohiya, may independiyenteng R&D at mga kakayahan sa disenyo, at maaaring magbigay ng customized na produksyon para sa bawat customer.