- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

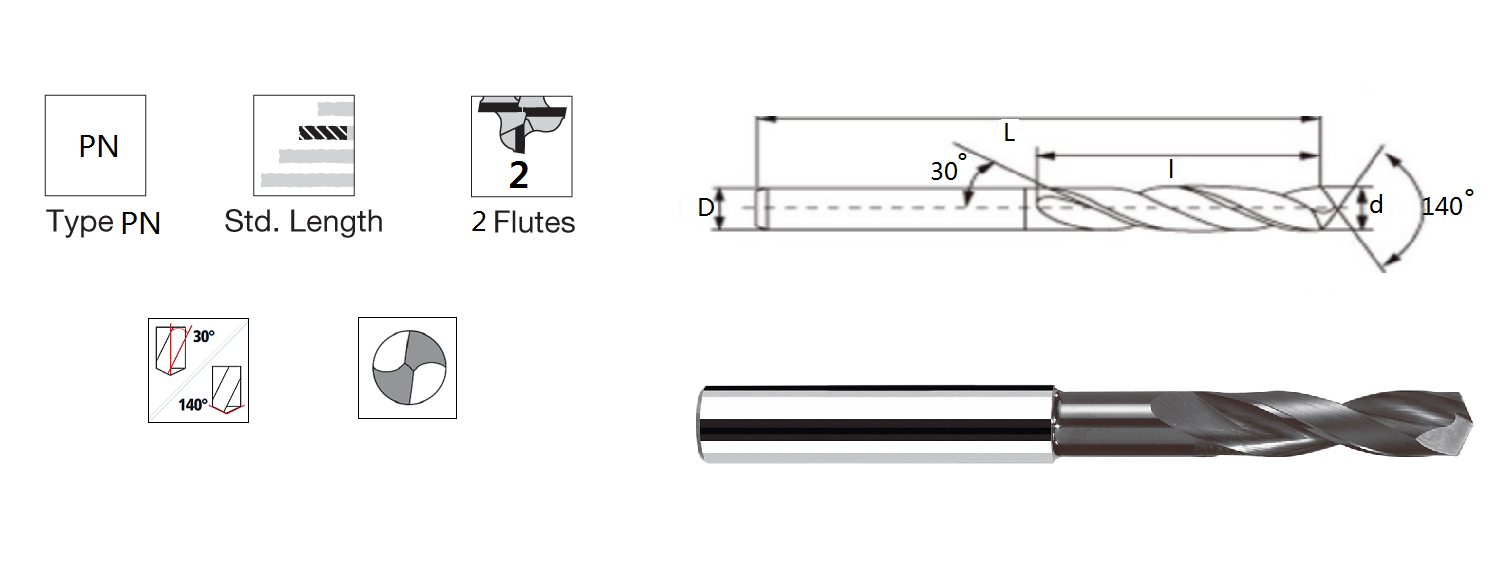

Volfram karbidi Daşarky sowadyş matkasy

Daşarky sowadyş türgenleşigi

HJDK550 seriýasy-Daşarky sowadyş türgenleşigi

Polat, poslamaýan polat, çoýun, reňkli material burawlamak üçin amatly.

Nano örtük AlTiN

Material: wolfram karbidi

Göçme manyda:

Polat materiallaryny çylşyrymly işlemek üçin HJDK550 burawy işlenip düzüldi. Cuttingokary kesiş gymmatlyklary we yzygiderli gowy deşik hili bilen güýçli täsir galdyrýar. Specialörite mikro-geometriýanyň kömegi bilen has durnukly we takyk kesiş gyrasy öndürilýär. Webiň inçelmegi we tüýdük profiliniň gaty tekiz bolmagy, buraw bilen çipiň arasyndaky sürtülmäni azaldar. Işleýiş temperaturasy peselýär we çip ewakuasiýasy gowulaşýar. Kesiji güýçler azalýar. Bu gural aýratynlyklary, iň ýokary deşik hiline we gural ömrüne getirýär.

Aýratynlyklary:

Polat, poslamaýan polat, çoýun, reňkli material burawlamak üçin amatly.

Stub kesmek, ajaýyp öz-özüne ukyplylyk.

Radial nokat, kiçi kesiş garşylygy.

Dodak gysgyç, ýokary iýmit tizligi, has ýokary netijelilik.

Adaty ululygy:

Karbid türgenleşikleri

| Sargyt kody | Daşarky diametri | Fleýta uzynlygy | Umumy uzynlyk | Şankyň diametri |

| (D) | (l) | (L) | (D) | |

| HJDK550-005S | 0.5 | 6 | 26 | 0.5 |

| HJDK550-006S | 0.6 | 6 | 26 | 0.6 |

| HJDK550-007S | 0.7 | 6 | 26 | 0.7 |

| HJDK550-008S | 0.8 | 6 | 26 | 0.8 |

| HJDK550-009S | 0.9 | 6 | 26 | 0.9 |

| HJDK550-0100S | 1 | 6 | 26 | 1 |

| HJDK550-011S | 1.1 | 7 | 28 | 1.1 |

| HJDK550-012S | 1.2 | 8 | 30 | 1.2 |

| HJDK550-013S | 1.3 | 8 | 30 | 1.3 |

| HJDK550-014S | 1.4 | 9 | 32 | 1.4 |

| HJDK550-015S | 1.5 | 9 | 32 | 1.5 |

| HJDK550-016S | 1.6 | 10 | 34 | 1.6 |

| HJDK550-017S | 1.7 | 10 | 34 | 1.7 |

| HJDK550-018S | 1.8 | 11 | 36 | 1.8 |

| HJDK550-019S | 1.9 | 11 | 36 | 1.9 |

| HJDK550-020S | 2 | 12 | 38 | 2 |

| HJDK550-021S | 2.1 | 12 | 38 | 3 |

| HJDK550-022S | 2.2 | 13 | 40 | 3 |

| HJDK550-023S | 2.3 | 13 | 40 | 3 |

| HJDK550-024S | 2.4 | 14 | 43 | 3 |

| HJDK550-025S | 2.5 | 14 | 43 | 3 |

| HJDK550-026S | 2.6 | 14 | 43 | 3 |

| HJDK550-027S | 2.7 | 16 | 46 | 3 |

| HJDK550-028S | 2.8 | 16 | 46 | 3 |

| HJDK550-029S | 2.9 | 16 | 46 | 3 |

| HJDK550-030S | 3 | 16 | 46 | 3 |

| HJDK550-031S | 3.1 | 18 | 49 | 4 |

| HJDK550-032S | 3.2 | 18 | 49 | 4 |

| HJDK550-033S | 3.3 | 18 | 49 | 4 |

| HJDK550-034S | 3.4 | 20 | 52 | 4 |

| HJDK550-035S | 3.5 | 20 | 52 | 4 |

| HJDK550-036S | 3.6 | 20 | 52 | 4 |

| HJDK550-037S | 3.7 | 20 | 52 | 4 |

| HJDK550-038S | 3.8 | 20 | 52 | 4 |

| HJDK550-039S | 3.9 | 22 | 55 | 4 |

| HJDK550-040S | 4 | 22 | 55 | 4 |

| HJDK550-041S | 4.1 | 22 | 55 | 5 |

| HJDK550-042S | 4.2 | 22 | 55 | 5 |

| HJDK550-043S | 4.3 | 22 | 55 | 5 |

| HJDK550-044S | 4.4 | 24 | 55 | 5 |

| HJDK550-045S | 4.5 | 24 | 55 | 5 |

| HJDK550-046S | 4.6 | 24 | 58 | 5 |

| HJDK550-047S | 4.7 | 24 | 58 | 5 |

| HJDK550-048S | 4.8 | 24 | 58 | 5 |

| HJDK550-049S | 4.9 | 26 | 58 | 5 |

| HJDK550 -050S | 5 | 26 | 58 | 5 |

| HJDK550-051S | 5.1 | 26 | 62 | 5.1 |

| HJDK550-052S | 5.2 | 26 | 62 | 5.2 |

| HJDK550-053S | 5.3 | 28 | 62 | 5.3 |

| HJDK550-054S | 5.4 | 28 | 62 | 5.4 |

| HJDK550-055S | 5.5 | 28 | 66 | 5.5 |

| HJDK550-056S | 5.6 | 28 | 66 | 5.6 |

| HJDK550-057S | 5.7 | 28 | 66 | 5.7 |

| HJDK550-058S | 5.8 | 28 | 66 | 5.8 |

| HJDK550-059S | 5.9 | 28 | 66 | 5.9 |

| HJDK550-060S | 6 | 31 | 66 | 6 |

| HJDK550-061S | 6.1 | 31 | 70 | 7 |

| HJDK550-062S | 6.2 | 31 | 70 | 7 |

| HJDK550-063S | 6.3 | 31 | 70 | 7 |

| HJDK550 -064S | 6.4 | 31 | 70 | 7 |

| HJDK550 -065S | 6.5 | 31 | 70 | 7 |

| HJDK550-066S | 6.6 | 31 | 70 | 7 |

| HJDK550-067S | 6.7 | 31 | 70 | 7 |

| HJDK550-068S | 6.8 | 34 | 74 | 7 |

| HJDK550-069S | 6.9 | 34 | 74 | 7 |

| HJDK550-070S | 7 | 34 | 74 | 7 |

| HJDK550-071S | 7.1 | 34 | 74 | 8 |

| HJDK550-072S | 7.2 | 34 | 74 | 8 |

| HJDK550-073S | 7.3 | 34 | 74 | 8 |

| HJDK550-074S | 7.4 | 34 | 74 | 8 |

| HJDK550-075S | 7.5 | 34 | 74 | 8 |

| HJDK550-076S | 7.6 | 37 | 79 | 8 |

| HJDK550-077S | 7.7 | 37 | 79 | 8 |

| HJDK550-078S | 7.8 | 37 | 79 | 8 |

| HJDK550-079S | 7.9 | 37 | 79 | 8 |

| HJDK550-080S | 8 | 37 | 79 | 8 |

| HJDK550-081S | 8.1 | 37 | 79 | 9 |

| HJDK550 -082S | 8.2 | 37 | 79 | 9 |

| HJDK550 -083S | 8.3 | 37 | 79 | 9 |

| HJDK550 -084S | 8.4 | 37 | 79 | 9 |

| HJDK550-085S | 8.5 | 37 | 79 | 9 |

| HJDK550-086S | 8.6 | 40 | 84 | 9 |

| HJDK550-087S | 8.7 | 40 | 84 | 9 |

| HJDK550-088S | 8.8 | 40 | 84 | 9 |

| HJDK550-089S | 8.9 | 40 | 84 | 9 |

| HJDK550-090S | 9 | 40 | 84 | 9 |

| HJDK550-091S | 9.1 | 40 | 84 | 10 |

| HJDK550-092S | 9.2 | 40 | 84 | 10 |

| HJDK550-093S | 9.3 | 40 | 84 | 10 |

| HJDK550-094S | 9.4 | 40 | 84 | 10 |

HJDK550 Karbid türgenleşikleri

| Sargyt kody | Daşarky diametri | Fleýta uzynlygy | Umumy uzynlyk | Şankyň diametri |

| (D) | (l) | (L) | (D) | |

| HJDK550-095S | 9.5 | 40 | 84 | 10 |

| HJDK550-096S | 9.6 | 43 | 89 | 10 |

| HJDK550-097S | 9.7 | 43 | 89 | 10 |

| HJDK550-098S | 9.8 | 43 | 89 | 10 |

| HJDK550-099S | 9.9 | 43 | 89 | 10 |

| HJDK550-100S | 10 | 43 | 89 | 10 |

| HJDK550-101S | 10.1 | 43 | 89 | 11 |

| HJDK550-102S | 10.2 | 43 | 89 | 11 |

| HJDK550-103S | 10.3 | 43 | 89 | 11 |

| HJDK550-104S | 10.4 | 43 | 89 | 11 |

| HJDK550-105S | 10.5 | 43 | 89 | 11 |

| HJDK550-106S | 10.6 | 43 | 89 | 11 |

| HJDK550-107S | 10.7 | 43 | 89 | 11 |

| HJDK550-108S | 10.8 | 43 | 89 | 11 |

| HJDK550-109S | 10.9 | 43 | 89 | 11 |

| HJDK550-110S | 11 | 47 | 95 | 11 |

| HJDK550-111S | 11.1 | 47 | 95 | 12 |

| HJDK550-112S | 11.2 | 47 | 95 | 12 |

| HJDK550-113S | 11.3 | 47 | 95 | 12 |

| HJDK550-114S | 11.4 | 47 | 95 | 12 |

| HJDK550-115S | 11.5 | 47 | 95 | 12 |

| HJDK550-116S | 11.6 | 47 | 95 | 12 |

| HJDK550-117S | 11.7 | 47 | 95 | 12 |

| HJDK550-118S | 11.8 | 47 | 95 | 12 |

| HJDK550-119S | 11.9 | 47 | 95 | 12 |

| HJDK550-120S | 12 | 51 | 102 | 12 |

| HJDK550-121S | 12.1 | 51 | 102 | 13 |

| HJDK550-122S | 12.2 | 51 | 102 | 13 |

| HJDK550-123S | 12.3 | 51 | 102 | 13 |

| HJDK550-124S | 12.4 | 51 | 102 | 13 |

| HJDK550-125S | 12.5 | 51 | 102 | 13 |

| HJDK550-126S | 12.6 | 51 | 102 | 13 |

| HJDK550-127S | 12.7 | 51 | 102 | 13 |

| HJDK550-128S | 12.8 | 51 | 102 | 13 |

| HJDK550-129S | 12.9 | 51 | 102 | 13 |

| HJDK550-130S | 13 | 51 | 102 | 13 |

HJDK550 standart türgenleşikler:

| Sargyt kody | Daşarky diametri | Fleýta uzynlygy |

| (D) | (l) | |

| HJDK550-0030 | 0.3 | 5.5 |

| HJDK550-0035 | 0.35 | 5.5 |

| HJDK550-0040 | 0.4 | 7 |

| HJDK550-0045 | 0.45 | 7 |

| HJDK550-0050 | 0.5 | 8.5 |

| HJDK550-0055 | 0.55 | 8.5 |

| HJDK550-0060 | 0.6 | 9.5 |

| HJDK550-0065 | 0.65 | 9.5 |

| HJDK550-0070 | 0.7 | 9.5 |

| HJDK550-0075 | 0.75 | 9.5 |

| HJDK550-0080 | 0.8 | 9.5 |

| HJDK550-0085 | 0.85 | 9.5 |

| HJDK550-0090 | 0.9 | 9.5 |

| HJDK550-0095 | 0.95 | 9.5 |

| HJDK550-0100 | 1 | 10.5 |

| HJDK550-0105 | 1.05 | 10.5 |

| HJDK550-0110 | 1.1 | 10.5 |

| HJDK550-0115 | 1.15 | 10.5 |

| HJDK550-0120 | 1.2 | 10.5 |

| HJDK550-0125 | 1.25 | 10.5 |

| HJDK550-0130 | 1.3 | 12 |

| HJDK550-0135 | 1.35 | 12 |

| HJDK550-0140 | 1.4 | 12 |

| HJDK550-0145 | 1.45 | 12 |

| HJDK550-0150 | 1.5 | 12 |

| HJDK550-0155 | 1.55 | 12 |

| HJDK550-0160 | 1.6 | 12 |

| HJDK550-0165 | 1.65 | 12 |

| HJDK550-0170 | 1.7 | 12 |

| HJDK550-0175 | 1.75 | 12 |

| HJDK550-0180 | 1.8 | 12 |

| HJDK550-0185 | 1.85 | 12 |

| HJDK550-0190 | 1.9 | 12 |

| HJDK550-0195 | 1.95 | 12 |

| HJDK550-0200 | 2 | 12 |

| HJDK550-0205 | 2.05 | 12 |

| HJDK550-0210 | 2.1 | 12 |

| HJDK550-0215 | 2.15 | 12 |

| HJDK550-0220 | 2.2 | 12 |

| HJDK550-0225 | 2.25 | 12 |

| HJDK550-0230 | 2.3 | 12 |

| HJDK550-0235 | 2.35 | 12 |

| HJDK550-0240 | 2.4 | 12 |

| HJDK550-0245 | 2.45 | 12 |

| HJDK550-0250 | 2.5 | 12 |

| HJDK550-0255 | 2.55 | 12 |

| HJDK550-0260 | 2.6 | 12 |

| HJDK550-0265 | 2.65 | 12 |

| HJDK550-0270 | 2.7 | 12 |

| HJDK550-0275 | 2.75 | 12 |

| HJDK550-0280 | 2.8 | 12 |

| HJDK550-0285 | 2.85 | 12 |

| HJDK550-0290 | 2.9 | 12 |

| HJDK550-0295 | 2.95 | 12 |

| HJDK550-0300 | 3 | 12 |

| HJDK550-0305 | 3.05 | 12 |

| HJDK550-0310 | 3.1 | 12 |

| HJDK550-0315 | 3.15 | 12 |

| HJDK550-03175 | 3.175 | 12 |

Müşderiniň talaplaryna laýyklykda 3D, 5D, 8D türgenleşiklerini ýa-da adaty bolşy ýaly standart däl türgenleşikleri öndürip bileris. Şeýle hem adaty bolmadyk ahyrky degirmenleri öndürip bileris.

Gural material düzümi:

1.Fiziki aýratynlyklary:

A) Gatylygy 92,8 HRA-dan uly ýa-da deňdir ;

B) Dykyzlygy 14,2 g / sm³ than-dan uly ýa-da deňdir

C) 4200 N / mm² than uly ýa-da deň bolan TRS

D) ETA fazasynyň şerti ýok ;

E) Beýleki materiallar bilen hapalanma ýok ;

F) gözenek = A00 / B00 / C00 ;

G) Bitewi we yzygiderli däne ululygy. Dänäniň ululygy görkezilenlerden uly bolup bilmez.

H) Diňe hrom karbid dänesiniň ösüş inhibitory.

2.Hemme önümçilik gurallary, örtükler Germaniýada, Şweýsariýada, gaýtadan işleýän enjamlarda ulanylýar ;

Örtük:

Nano örtük AlTiN

Aýratynlyklary we wezipesi

1 、 Alýuminiň ýokary mukdary ajaýyp gyzgynlygy we okislenmä garşylygy üpjün edýär.

2 、 methodörite usul örtügiň gurluşyny optimallaşdyrýar, durnuklylygy ep-esli gowulandyrýar, ýerüsti damjalaryň sanyny azaldýar.

| Daşarky sowadyş buraw işiniň parametri: | |||||||||||

| Iş materialy | Kesiş tizligi | Iýmit tizligi (mm / rev) | |||||||||

| (m / min) | |||||||||||

| Daşarky sowatma | D3 | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D18 | D20 | |

| buraw | |||||||||||

| Pes uglerod polat, uzyn çip | 100 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<125HB) | 80 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Pes uglerod polat, gysga kesilen, | 100 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| aňsat kesilen polat | 75 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<125HB) | 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Carbonokary uglerod polat | 90 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| we orta uglerod polat | 70 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<25HRC) | 45 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Garylan polat, gural polat | 90 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<35HRC) | 70 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 45 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Garylan polat, gural polat | 80 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| (35-48HRC) | 60 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| 40 | 0.14 | 0.17 | 0.22 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| PH we ferrit, martensit polat | 70 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| (<35HRC) | 50 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| 30 | 0.14 | 0.17 | 0.23 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| Austenit poslamaýan polat | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.14 | |

| (130-200HB) | 0.08 | 0.1 | 0.12 | 0.13 | 0.15 | 0.17 | 0.18 | 0.2 | 0.22 | 0.24 | |

| 0.1 | 0.12 | 0.14 | 0.18 | 0.2 | 0.22 | 0.24 | 0.24 | 0.26 | 0.28 | ||

| Güýçli austenit | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 | |

| poslamaýan polatdan ýasalan | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 | |

| (<25HRC) | 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | |

| Dupleks poslamaýan polat | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 | |

| (<30HRC) | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 | |

| 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | ||

| Çal demir | 100 | 0.13 | 0.15 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 |

| (<32HRC) | 80 | 0.17 | 0.02 | 0.26 | 0.32 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | 0.48 |

| 60 | 0.21 | 0.26 | 0.32 | 0.4 | 0.42 | 0.46 | 0.5 | 0.52 | 0.54 | 0.56 | |

| Orta garyndy demir | 100 | 0.11 | 0.13 | 0.15 | 0.17 | 0.22 | 0.22 | 0.24 | 0.26 | 0.3 | 0.34 |

| gaýtadan işlemek kynlygy, | 80 | 0.15 | 0.18 | 0.23 | 0.26 | 0.28 | 0.34 | 0.35 | 0.4 | 0.4 | 0.43 |

| düwünli demir | 60 | 0.18 | 0.22 | 0.27 | 0.38 | 0.38 | 0.42 | 0.44 | 0.48 | 0.46 | 0.5 |

| (<28HRC) | |||||||||||

| Çekip bolmaýan ýokary garyndy demir, | 90 | 0.06 | 0.08 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.23 | 0.23 |

| düwünli demir | 70 | 0.09 | 0.1 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.28 | 0.29 |

| (<28HRC) | 60 | 0.11 | 0.13 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.34 | 0.35 |

| Alýumin garyndysy | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si<12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Alýumin garyndysyny guýuň | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si<12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Alýumin garyndysyny guýuň | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si>12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Mis, mis garyndysy | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (<200HB) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

Üns beriň:

Iş bölekleriniň we maşynyň durnuklydygyna göz ýetiriň we takyk saklaýjyny ulanyň, gidrawliki çukurlary, ýokary hilli kolletleri ulanyň.

Jemi görkezilen gutarmagyň (TIR) 0.02 mm-den pesdigine göz ýetiriň.

Maslahat berilýän kesiş ýagdaýy, suwy erginli ulanmak üçin amatlydyr.

Guralyň ululygy tablisada ýok bolsa. Kesiş parametrleriniň pyçak diametriniň ululygyna tablisa şkafyna serediň, gaýtadan işlenende hakyky iş şertlerine görä kesiş parametrlerini sazlaň.

Şereketde poroşok çig malyny taýýarlamakdan, galyndy ýasamakdan, basmakdan, basyşy süzmekden, üwemekden, örtmekden we örtükden başlap, pyçak öndürmek prosesi enjamlaryny öndürmek liniýasy bar. Esasy materialyň, çukuryň gurluşyna, karbid NC goýmalarynyň takyk emele gelmegine we ýerüsti örtügine ünsi jemleýär we karbid NC goýmalarynyň işleýiş netijeliligini, hyzmat ediş möhletini we beýleki kesiş aýratynlyklaryny yzygiderli ýokarlandyrýar. On ýyldan gowrak ylmy gözleglerden we innowasiýalardan soň, kompaniýa birnäçe garaşsyz esasy tehnologiýalary özleşdirdi, garaşsyz gözleg we dizaýn mümkinçiliklerine eýe we her bir müşderi üçin aýratyn önüm öndürip biler.