- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

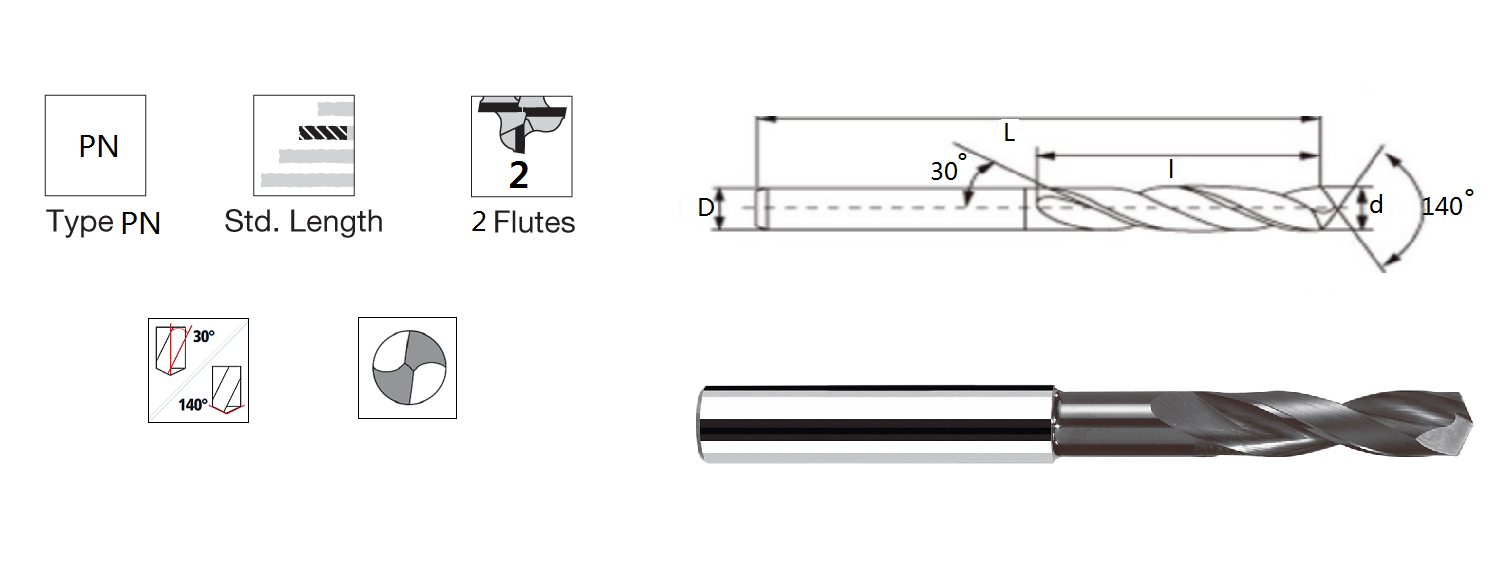

Tungsten CARBIDE Drill ya nje ya baridi

Uchimbaji wa baridi wa nje

HJDK550 mfululizo-Uchimbaji wa baridi wa nje

Yanafaa kwa ajili ya kuchimba chuma, chuma cha pua, chuma cha kutupwa, nyenzo zisizo na feri.

Mipako ya Nano AlTiN

Nyenzo: tungsten carbudi

Kauli halisi:

HJDK550 drill ilianzishwa kwa ajili ya uchakataji changamano wa nyenzo za chuma . Inafanya hisia kali na maadili yake ya juu ya kukata na ubora mzuri wa shimo mara kwa mara. Upeo wa kukata hasa imara na sahihi hutolewa shukrani kwa micro-jiometri maalum. Uso laini kabisa wa ukondefu wa wavuti na wasifu wa filimbi hupunguza msuguano kati ya kuchimba visima na chip. Joto la machining limepunguzwa na uokoaji wa chip unaboreshwa. Nguvu za kukata hupunguzwa. Vipengele hivi vya zana husababisha ubora wa juu zaidi wa shimo na maisha ya zana.

vipengele:

Yanafaa kwa ajili ya kuchimba chuma, chuma cha pua, chuma cha kutupwa, nyenzo zisizo na feri.

Pata patasi, uwezo bora wa kujitegemea.

Hatua ya radial, upinzani mdogo wa kukata.

Chamfer ya midomo, kiwango cha juu cha kulisha, ufanisi wa juu.

Ukubwa wa kawaida:

Mazoezi ya Carbide

| Kuagiza msimbo | Nje Kipenyo | Urefu Flute | Urefu Kwa Jumla | Kipenyo cha Shank |

| (D) | (l) | (L) | (D) | |

| HJDK550-005S | 0.5 | 6 | 26 | 0.5 |

| HJDK550-006S | 0.6 | 6 | 26 | 0.6 |

| HJDK550-007S | 0.7 | 6 | 26 | 0.7 |

| HJDK550-008S | 0.8 | 6 | 26 | 0.8 |

| HJDK550-009S | 0.9 | 6 | 26 | 0.9 |

| HJDK550-0100S | 1 | 6 | 26 | 1 |

| HJDK550-011S | 1.1 | 7 | 28 | 1.1 |

| HJDK550-012S | 1.2 | 8 | 30 | 1.2 |

| HJDK550-013S | 1.3 | 8 | 30 | 1.3 |

| HJDK550-014S | 1.4 | 9 | 32 | 1.4 |

| HJDK550-015S | 1.5 | 9 | 32 | 1.5 |

| HJDK550-016S | 1.6 | 10 | 34 | 1.6 |

| HJDK550-017S | 1.7 | 10 | 34 | 1.7 |

| HJDK550-018S | 1.8 | 11 | 36 | 1.8 |

| HJDK550-019S | 1.9 | 11 | 36 | 1.9 |

| HJDK550-020S | 2 | 12 | 38 | 2 |

| HJDK550-021S | 2.1 | 12 | 38 | 3 |

| HJDK550-022S | 2.2 | 13 | 40 | 3 |

| HJDK550-023S | 2.3 | 13 | 40 | 3 |

| HJDK550-024S | 2.4 | 14 | 43 | 3 |

| HJDK550-025S | 2.5 | 14 | 43 | 3 |

| HJDK550-026S | 2.6 | 14 | 43 | 3 |

| HJDK550-027S | 2.7 | 16 | 46 | 3 |

| HJDK550-028S | 2.8 | 16 | 46 | 3 |

| HJDK550-029S | 2.9 | 16 | 46 | 3 |

| HJDK550-030S | 3 | 16 | 46 | 3 |

| HJDK550-031S | 3.1 | 18 | 49 | 4 |

| HJDK550-032S | 3.2 | 18 | 49 | 4 |

| HJDK550-033S | 3.3 | 18 | 49 | 4 |

| HJDK550-034S | 3.4 | 20 | 52 | 4 |

| HJDK550-035S | 3.5 | 20 | 52 | 4 |

| HJDK550-036S | 3.6 | 20 | 52 | 4 |

| HJDK550-037S | 3.7 | 20 | 52 | 4 |

| HJDK550-038S | 3.8 | 20 | 52 | 4 |

| HJDK550-039S | 3.9 | 22 | 55 | 4 |

| HJDK550-040S | 4 | 22 | 55 | 4 |

| HJDK550-041S | 4.1 | 22 | 55 | 5 |

| HJDK550-042S | 4.2 | 22 | 55 | 5 |

| HJDK550-043S | 4.3 | 22 | 55 | 5 |

| HJDK550-044S | 4.4 | 24 | 55 | 5 |

| HJDK550-045S | 4.5 | 24 | 55 | 5 |

| HJDK550-046S | 4.6 | 24 | 58 | 5 |

| HJDK550-047S | 4.7 | 24 | 58 | 5 |

| HJDK550-048S | 4.8 | 24 | 58 | 5 |

| HJDK550-049S | 4.9 | 26 | 58 | 5 |

| HJDK550 -050S | 5 | 26 | 58 | 5 |

| HJDK550-051S | 5.1 | 26 | 62 | 5.1 |

| HJDK550-052S | 5.2 | 26 | 62 | 5.2 |

| HJDK550-053S | 5.3 | 28 | 62 | 5.3 |

| HJDK550-054S | 5.4 | 28 | 62 | 5.4 |

| HJDK550-055S | 5.5 | 28 | 66 | 5.5 |

| HJDK550-056S | 5.6 | 28 | 66 | 5.6 |

| HJDK550-057S | 5.7 | 28 | 66 | 5.7 |

| HJDK550-058S | 5.8 | 28 | 66 | 5.8 |

| HJDK550-059S | 5.9 | 28 | 66 | 5.9 |

| HJDK550-060S | 6 | 31 | 66 | 6 |

| HJDK550-061S | 6.1 | 31 | 70 | 7 |

| HJDK550-062S | 6.2 | 31 | 70 | 7 |

| HJDK550-063S | 6.3 | 31 | 70 | 7 |

| HJDK550 -064S | 6.4 | 31 | 70 | 7 |

| HJDK550 -065S | 6.5 | 31 | 70 | 7 |

| HJDK550-066S | 6.6 | 31 | 70 | 7 |

| HJDK550-067S | 6.7 | 31 | 70 | 7 |

| HJDK550-068S | 6.8 | 34 | 74 | 7 |

| HJDK550-069S | 6.9 | 34 | 74 | 7 |

| HJDK550-070S | 7 | 34 | 74 | 7 |

| HJDK550-071S | 7.1 | 34 | 74 | 8 |

| HJDK550-072S | 7.2 | 34 | 74 | 8 |

| HJDK550-073S | 7.3 | 34 | 74 | 8 |

| HJDK550-074S | 7.4 | 34 | 74 | 8 |

| HJDK550-075S | 7.5 | 34 | 74 | 8 |

| HJDK550-076S | 7.6 | 37 | 79 | 8 |

| HJDK550-077S | 7.7 | 37 | 79 | 8 |

| HJDK550-078S | 7.8 | 37 | 79 | 8 |

| HJDK550-079S | 7.9 | 37 | 79 | 8 |

| HJDK550-080S | 8 | 37 | 79 | 8 |

| HJDK550-081S | 8.1 | 37 | 79 | 9 |

| HJDK550 -082S | 8.2 | 37 | 79 | 9 |

| HJDK550 -083S | 8.3 | 37 | 79 | 9 |

| HJDK550 -084S | 8.4 | 37 | 79 | 9 |

| HJDK550-085S | 8.5 | 37 | 79 | 9 |

| HJDK550-086S | 8.6 | 40 | 84 | 9 |

| HJDK550-087S | 8.7 | 40 | 84 | 9 |

| HJDK550-088S | 8.8 | 40 | 84 | 9 |

| HJDK550-089S | 8.9 | 40 | 84 | 9 |

| HJDK550-090S | 9 | 40 | 84 | 9 |

| HJDK550-091S | 9.1 | 40 | 84 | 10 |

| HJDK550-092S | 9.2 | 40 | 84 | 10 |

| HJDK550-093S | 9.3 | 40 | 84 | 10 |

| HJDK550-094S | 9.4 | 40 | 84 | 10 |

Mazoezi ya Carbide ya HJDK550

| Kuagiza msimbo | Nje Kipenyo | Urefu Flute | Urefu Kwa Jumla | Kipenyo cha Shank |

| (D) | (l) | (L) | (D) | |

| HJDK550-095S | 9.5 | 40 | 84 | 10 |

| HJDK550-096S | 9.6 | 43 | 89 | 10 |

| HJDK550-097S | 9.7 | 43 | 89 | 10 |

| HJDK550-098S | 9.8 | 43 | 89 | 10 |

| HJDK550-099S | 9.9 | 43 | 89 | 10 |

| HJDK550-100S | 10 | 43 | 89 | 10 |

| HJDK550-101S | 10.1 | 43 | 89 | 11 |

| HJDK550-102S | 10.2 | 43 | 89 | 11 |

| HJDK550-103S | 10.3 | 43 | 89 | 11 |

| HJDK550-104S | 10.4 | 43 | 89 | 11 |

| HJDK550-105S | 10.5 | 43 | 89 | 11 |

| HJDK550-106S | 10.6 | 43 | 89 | 11 |

| HJDK550-107S | 10.7 | 43 | 89 | 11 |

| HJDK550-108S | 10.8 | 43 | 89 | 11 |

| HJDK550-109S | 10.9 | 43 | 89 | 11 |

| HJDK550-110S | 11 | 47 | 95 | 11 |

| HJDK550-111S | 11.1 | 47 | 95 | 12 |

| HJDK550-112S | 11.2 | 47 | 95 | 12 |

| HJDK550-113S | 11.3 | 47 | 95 | 12 |

| HJDK550-114S | 11.4 | 47 | 95 | 12 |

| HJDK550-115S | 11.5 | 47 | 95 | 12 |

| HJDK550-116S | 11.6 | 47 | 95 | 12 |

| HJDK550-117S | 11.7 | 47 | 95 | 12 |

| HJDK550-118S | 11.8 | 47 | 95 | 12 |

| HJDK550-119S | 11.9 | 47 | 95 | 12 |

| HJDK550-120S | 12 | 51 | 102 | 12 |

| HJDK550-121S | 12.1 | 51 | 102 | 13 |

| HJDK550-122S | 12.2 | 51 | 102 | 13 |

| HJDK550-123S | 12.3 | 51 | 102 | 13 |

| HJDK550-124S | 12.4 | 51 | 102 | 13 |

| HJDK550-125S | 12.5 | 51 | 102 | 13 |

| HJDK550-126S | 12.6 | 51 | 102 | 13 |

| HJDK550-127S | 12.7 | 51 | 102 | 13 |

| HJDK550-128S | 12.8 | 51 | 102 | 13 |

| HJDK550-129S | 12.9 | 51 | 102 | 13 |

| HJDK550-130S | 13 | 51 | 102 | 13 |

Uchimbaji wa Kawaida wa HJDK550:

| Kuagiza msimbo | Nje Kipenyo | Urefu Flute |

| (D) | (l) | |

| HJDK550-0030 | 0.3 | 5.5 |

| HJDK550-0035 | 0.35 | 5.5 |

| HJDK550-0040 | 0.4 | 7 |

| HJDK550-0045 | 0.45 | 7 |

| HJDK550-0050 | 0.5 | 8.5 |

| HJDK550-0055 | 0.55 | 8.5 |

| HJDK550-0060 | 0.6 | 9.5 |

| HJDK550-0065 | 0.65 | 9.5 |

| HJDK550-0070 | 0.7 | 9.5 |

| HJDK550-0075 | 0.75 | 9.5 |

| HJDK550-0080 | 0.8 | 9.5 |

| HJDK550-0085 | 0.85 | 9.5 |

| HJDK550-0090 | 0.9 | 9.5 |

| HJDK550-0095 | 0.95 | 9.5 |

| HJDK550-0100 | 1 | 10.5 |

| HJDK550-0105 | 1.05 | 10.5 |

| HJDK550-0110 | 1.1 | 10.5 |

| HJDK550-0115 | 1.15 | 10.5 |

| HJDK550-0120 | 1.2 | 10.5 |

| HJDK550-0125 | 1.25 | 10.5 |

| HJDK550-0130 | 1.3 | 12 |

| HJDK550-0135 | 1.35 | 12 |

| HJDK550-0140 | 1.4 | 12 |

| HJDK550-0145 | 1.45 | 12 |

| HJDK550-0150 | 1.5 | 12 |

| HJDK550-0155 | 1.55 | 12 |

| HJDK550-0160 | 1.6 | 12 |

| HJDK550-0165 | 1.65 | 12 |

| HJDK550-0170 | 1.7 | 12 |

| HJDK550-0175 | 1.75 | 12 |

| HJDK550-0180 | 1.8 | 12 |

| HJDK550-0185 | 1.85 | 12 |

| HJDK550-0190 | 1.9 | 12 |

| HJDK550-0195 | 1.95 | 12 |

| HJDK550-0200 | 2 | 12 |

| HJDK550-0205 | 2.05 | 12 |

| HJDK550-0210 | 2.1 | 12 |

| HJDK550-0215 | 2.15 | 12 |

| HJDK550-0220 | 2.2 | 12 |

| HJDK550-0225 | 2.25 | 12 |

| HJDK550-0230 | 2.3 | 12 |

| HJDK550-0235 | 2.35 | 12 |

| HJDK550-0240 | 2.4 | 12 |

| HJDK550-0245 | 2.45 | 12 |

| HJDK550-0250 | 2.5 | 12 |

| HJDK550-0255 | 2.55 | 12 |

| HJDK550-0260 | 2.6 | 12 |

| HJDK550-0265 | 2.65 | 12 |

| HJDK550-0270 | 2.7 | 12 |

| HJDK550-0275 | 2.75 | 12 |

| HJDK550-0280 | 2.8 | 12 |

| HJDK550-0285 | 2.85 | 12 |

| HJDK550-0290 | 2.9 | 12 |

| HJDK550-0295 | 2.95 | 12 |

| HJDK550-0300 | 3 | 12 |

| HJDK550-0305 | 3.05 | 12 |

| HJDK550-0310 | 3.1 | 12 |

| HJDK550-0315 | 3.15 | 12 |

| HJDK550-03175 | 3.175 | 12 |

Tunaweza kuzalisha 3D, 5D, 8D drills kulingana na mahitaji ya mteja au mazoezi yasiyo ya kawaida kama yalivyobinafsishwa. Tunaweza pia kutoa vinu vya mwisho visivyo vya kawaida kama vilivyobinafsishwa.

Muundo wa nyenzo za zana:

1. Sifa za Kimwili:

A) Ugumu zaidi kuliko au sawa na 92.8 HRA;

B) Msongamano mkubwa kuliko au sawa na 14.2 g/cm³;

C) TRS kubwa kuliko au sawa na 4200 N/mm²;

D) Bila hali ya awamu ya ETA;

E) Hakuna uchafuzi wa nyenzo zingine;

F) Porosity = A00 / B00 / C00 ;

G) Ukubwa wa nafaka sawa na thabiti. Hakuna saizi ya nafaka inayoweza kuwa kubwa kuliko ilivyobainishwa.

H) Kizuizi cha ukuaji wa nafaka ya Chromium CARBIDE pekee.

2. Zana zote za uzalishaji, mipako hutumiwa nchini Ujerumani, Uswisi, vifaa vya kusindika;

Mipako:

Mipako ya Nano AlTiN

Sifa na Kazi

1, Maudhui ya juu ya alumini hutoa ugumu bora wa moto na upinzani wa oxidation.

2, Mbinu maalum huongeza muundo wa mipako, uthabiti ulioboreshwa kwa kiasi kikubwa, kupunguza idadi ya matone ya uso.

| Kigezo cha uendeshaji uchezeshaji upoeji wa nje: | |||||||||||

| Nyenzo za kazi | Kupunguza kasi | Kiwango cha milisho(mm/rev) | |||||||||

| (m/dakika) | |||||||||||

| Ubaridi wa nje | D3 | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D18 | D20 | |

| kuchimba visima | |||||||||||

| Chuma cha kaboni chini, chipu ndefu | 100 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<125HB) | 80 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Chuma cha kaboni chini, mfupi , | 100 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| chuma kukatwa kwa urahisi | 75 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<125HB) | 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Chuma cha kaboni ya high | 90 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| na chuma kaa wa wastani | 70 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<25HRC) | 45 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Aloi chuma, zana chuma | 90 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<35HRC) | 70 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 45 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Aloi chuma, chuma zana | 80 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| (35-48HRC) | 60 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| 40 | 0.14 | 0.17 | 0.22 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| PH na ferritic, chuma martensitic | 70 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| (<35HRC) | 50 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| 30 | 0.14 | 0.17 | 0.23 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| Austenitic chuma cha pua | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.14 | |

| (130-200HB) | 0.08 | 0.1 | 0.12 | 0.13 | 0.15 | 0.17 | 0.18 | 0.2 | 0.22 | 0.24 | |

| 0.1 | 0.12 | 0.14 | 0.18 | 0.2 | 0.22 | 0.24 | 0.24 | 0.26 | 0.28 | ||

| Nguvu ya juu austenitic | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 | |

| na chuma chuma cha pua kughushi | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 | |

| (<25HRC) | 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | |

| Duplex chuma cha pua | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 | |

| (<30HRC) | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 | |

| 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | ||

| Chuma kijivu | 100 | 0.13 | 0.15 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 |

| (<32HRC) | 80 | 0.17 | 0.02 | 0.26 | 0.32 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | 0.48 |

| 60 | 0.21 | 0.26 | 0.32 | 0.4 | 0.42 | 0.46 | 0.5 | 0.52 | 0.54 | 0.56 | |

| Aloi chuma cha wastani | 100 | 0.11 | 0.13 | 0.15 | 0.17 | 0.22 | 0.22 | 0.24 | 0.26 | 0.3 | 0.34 |

| ugumu wa usindikaji, | 80 | 0.15 | 0.18 | 0.23 | 0.26 | 0.28 | 0.34 | 0.35 | 0.4 | 0.4 | 0.43 |

| nodular chuma chuma | 60 | 0.18 | 0.22 | 0.27 | 0.38 | 0.38 | 0.42 | 0.44 | 0.48 | 0.46 | 0.5 |

| (<28HRC) | |||||||||||

| Aloi ya juu ya chuma isiyoweza kuguswa, | 90 | 0.06 | 0.08 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.23 | 0.23 |

| nodular chuma chuma | 70 | 0.09 | 0.1 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.28 | 0.29 |

| (<28HRC) | 60 | 0.11 | 0.13 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.34 | 0.35 |

| Aloi ya alumini ya kutengenezwa | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si<12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Tuma aloi ya alumini | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si<12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Tuma aloi ya alumini | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (Si>12%) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

| Shaba, aloi ya shaba | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 | |

| (<200HB) | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 | |

| 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | ||

Tahadhari:

Hakikisha peice ya kazi na mashine ni thabiti na unatumia kishikilia usahihi, tumia chucks za majimaji, chucks za ubora wa juu.

Hakikisha kuwa jumla ya mwisho iliyoonyeshwa (TIR) ni chini ya 0.02mm.

Hali iliyopendekezwa ya kukata inafaa kwa kutumia maji mumunyifu.

Ikiwa saizi ya chombo haipo kwenye meza. Tafadhali rejea chumbani ya meza kwa uteuzi wa ukubwa wa kipenyo cha blade ya vigezo vya kukata, kurekebisha vigezo vya kukata kulingana na hali halisi ya kazi wakati wa usindikaji.

Kampuni ina laini kamili ya utengenezaji wa vifaa vya utengenezaji wa vifaa kutoka kwa utayarishaji wa malighafi ya unga, kutengeneza ukungu, kukandamiza, kuweka shinikizo, kusaga, kupaka na kupaka baada ya matibabu. Inazingatia utafiti na uvumbuzi wa nyenzo za msingi, muundo wa groove, uundaji wa usahihi na mipako ya uso ya kuingizwa kwa carbudi NC, na inaboresha mara kwa mara ufanisi wa machining, maisha ya huduma na mali nyingine za kukata za kuingiza carbudi NC. Baada ya zaidi ya miaka kumi ya utafiti wa kisayansi na uvumbuzi, kampuni ina mastered idadi ya teknolojia ya msingi huru, ina kujitegemea R & D na kubuni uwezo, na inaweza kutoa customized uzalishaji kwa kila mteja.