- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

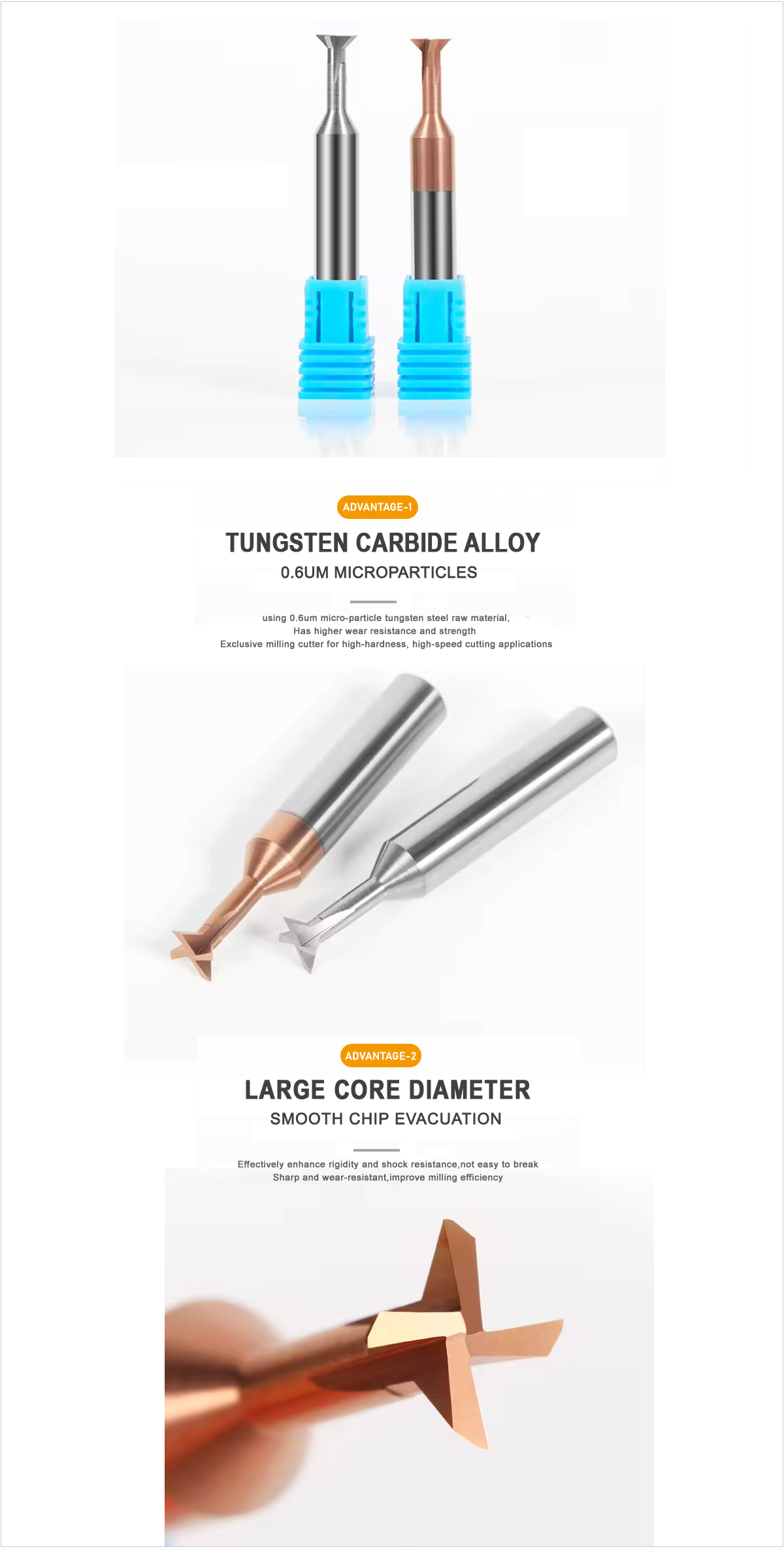

CNC e ikhethileng e sa tloaelehang Solid Carbide Dovetail E theha Endmill T-slot Milling Cutter

CNC Tools tšepe Aluminium Dovetail Groove Cutter T Slot

Sehahi sa 4-edge dovetail milling cutter

Customized Non-standard Dovetail End Milling Cutter

E sebetsa ka ho khetheha Tlhahisong ea Tloaelo e sa Tloaelehang ea mofuta oa T-Dovetail Cnc Tungsten Steel

| Lebitso | Dovetail Groove Trough T Slot T-Slot T-Milling Cutter |

| Lintho tse bonahalang | Carbide e entsoeng ka samente |

| Ho roala | AITIN/customized |

| Lenaka | 30°/45°/60°/90° |

| Bolelele ka kakaretso | 50-60mm kapa customized |

| E loketse bakeng sa | Tšepe e sa hloekang, Tšepe ea Carbon, Mold steel, Cast Iron,aluminium |

| Kopo | Side milling slotting, slotting e bopehileng joaloka T, ho kolopa ho tebileng, ho sila sefofane |

| Lintlha tsohle. e ka etsoa ka mokhoa o ikhethileng | |

Melemo ea rona:

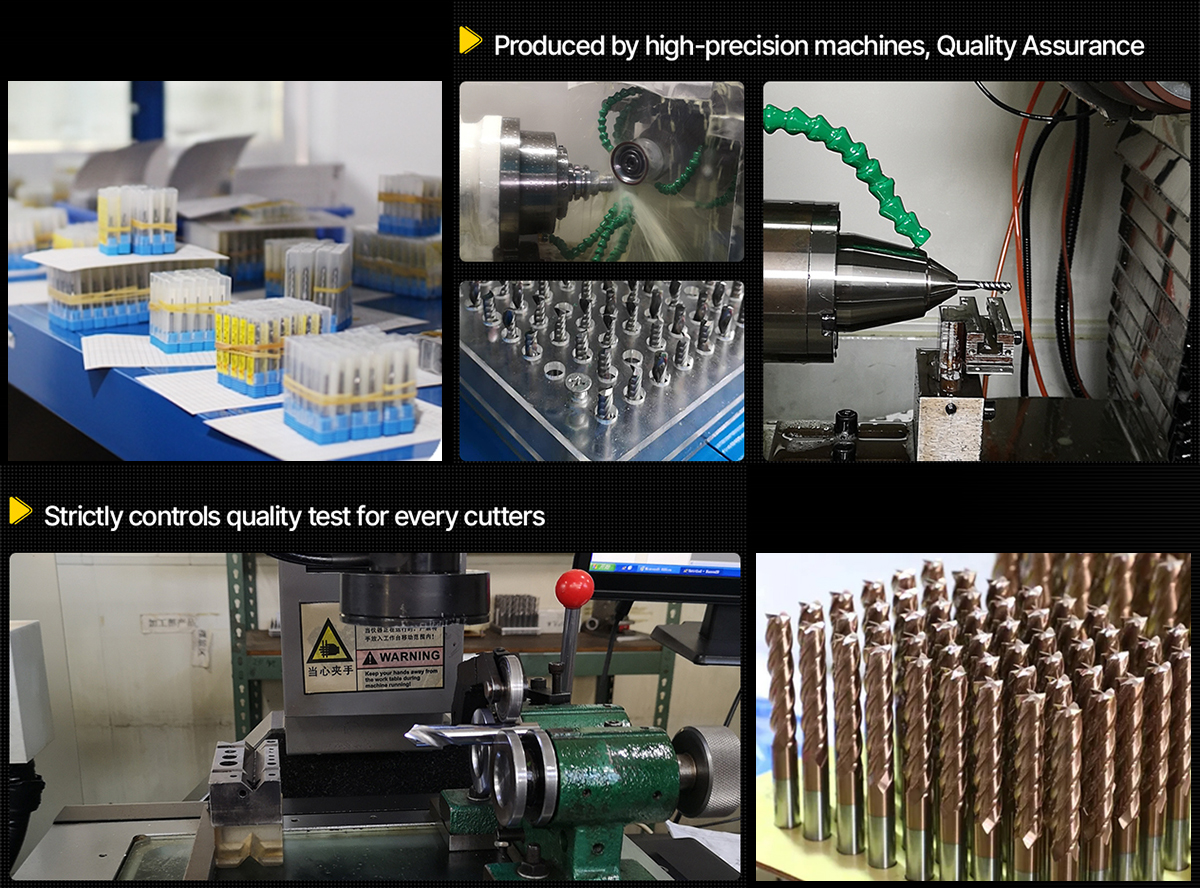

Sehlopha sa litsebi bakeng sa tlhahiso: E-ba le phihlelo ea lilemo tse fetang 10 bakeng sa tlhahiso ea carbide filed.

Ho fana ka potlako ho itšetlehile ka bokhoni bo phahameng ba tlhahiso.

Sistimi e tiileng ea taolo ea boleng: Netefatsa sehlahisoa sa rona ka boleng bo botle le bo tsitsitseng.

Boiphihlelo bo ruileng ka lihlahisoa tse ikhethileng.

Tšehetso ea tekheniki: E u thusa ho fumana tharollo e molemohali.

T-slot Dovetail End Mills

Li-cutters tsena tse khethehileng li entsoe ke mechini le mekhoa ea morao-rao, li nolofalletsa bareki ba rona ho ba le boiphihlelo bo botle ba ho slotting ba T. E hloka ho ts'oara sesebelisoa se thata mme e sebetse hantle ho qoba ho robeha. Sehlahisoa se nang le ho roala ke sa ts'ebetso ea tšepe le tse se nang letho bakeng sa aluminium.

Professional Carbide End Mill Manufacture

Boholo (bo tloaelehileng le bo sa tloaelehang)

Tloaelo:

li-cutters tsa rona tse tloaelehileng tsa ho roala carbide li koahela bophara ba bophara ho tloha ho 2mm ho isa ho 12mm ho kopana le tsamaiso ea machaba ea tlhahiso le litekanyetso tsa boleng.

E sa Tloaelehang:

Feme ea rona e ka etsa lihlahisoa tse sa tloaelehang ho latela setšoantšo sa theknoloji kapa lisampole.

Boholo bo tloaelehileng:

| Tlhaloso | ||||||

| Mill Diameter D1/(mm) | Lenaka | Mill Height H/(mm) | Qoba bophara d/(mm) | Bolelele ba Molala h/(mm) | Shank Diameter D2/(mm) | Kakaretso Bolelele L/(mm) |

| 2 | 60 | 0.32 | 0.9 | 4 | 4 | 50 |

| 3 | 60 | 0.47 | 1.4 | 6 | 4 | 50 |

| 4 | 60 | 0.62 | 1.9 | 8 | 4 | 50 |

| 5 | 60 | 0.79 | 2.3 | 10 | 6 | 50 |

| 6 | 60 | 0.94 | 2.8 | 10 | 6 | 50 |

| 8 | 60 | 1.29 | 3.6 | 12 | 8 | 60 |

| 10 | 60 | 1.61 | 4.5 | 15 | 10 | 60 |

| 12 | 60 | 1.94 | 5.4 | 18 | 12 | 60 |

| 2 | 45 | 0.55 | 0.9 | 4 | 4 | 50 |

| 3 | 45 | 0.8 | 1.4 | 6 | 4 | 50 |

| 4 | 45 | 1.05 | 1.9 | 8 | 4 | 50 |

| 5 | 45 | 1.35 | 2.3 | 10 | 6 | 50 |

| 6 | 45 | 1.6 | 2.8 | 10 | 6 | 50 |

| 8 | 45 | 2.2 | 3.6 | 12 | 8 | 60 |

| 10 | 45 | 2.75 | 4.5 | 15 | 10 | 60 |

| 12 | 45 | 3.3 | 5.4 | 18 | 12 | 60 |

| 2 | 30 | 0.96 | 0.9 | 4 | 4 | 50 |

| 3 | 30 | 1.4 | 1.4 | 6 | 4 | 50 |

| 4 | 30 | 1.84 | 1.9 | 8 | 4 | 50 |

| 5 | 30 | 2.37 | 2.3 | 10 | 6 | 50 |

| 6 | 30 | 2.81 | 2.8 | 10 | 6 | 50 |

| 8 | 30 | 3.86 | 3.6 | 12 | 8 | 60 |

| 10 | 30 | 4.82 | 4.5 | 15 | 10 | 60 |

| 12 | 30 | 5.79 | 5.4 | 18 | 12 | 60 |

Khamphani e na le mohala o felletseng oa tlhahiso ea lisebelisoa tsa lehare ho tloha ho tokiso ea lihlahisoa tse tala, ho etsa hlobo, ho hatella, ho sila ka khatello, ho sila, ho roala le ho roala ka mor'a kalafo. E shebane le lipatlisiso le boqapi ba lisebelisoa tsa motheo, sebopeho sa groove, ho etsoa ka nepo le ho roala ka holim'a li-carbide NC, 'me e lula e ntlafatsa ts'ebetso ea machining, bophelo ba ts'ebeletso le lisebelisoa tse ling tsa ho itšeha tsa carbide NC inserts. Ka mor'a lilemo tse fetang leshome tsa lipatlisiso tsa saense le mekhoa e mecha, k'hamphani e tseba mekhoa e mengata ea motheo e ikemetseng, e na le R&D e ikemetseng le bokhoni ba ho qapa, 'me e ka fana ka tlhahiso e ikhethileng bakeng sa moreki e mong le e mong.