- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

HJDK600 Inner Cooling Twist Drills bakeng sa Morero o Akaretsang

Inner Cooling Twist Drills for General Purpose - 副本 - 副本

HJDK600 Inner Cooling Twist Drills bakeng sa Morero o Akaretsang

E loketse bakeng sa ho cheka tšepe, tšepe e sa hloekang, tšepe e entsoeng ka tšepe, thepa e se nang ferrous.

Nano Coating AlTiN

lintho tse bonahalang: tungsten carbide

Tlhaloso ea sebele:

HJDK600 Inner Cooling Twist Drills bakeng sa Morero o Akaretsang

Li-drill tsa Carbide li fana ka litheko tse potlakang tsa ho itšeha, bophelo bo bolelele ba lisebelisoa, boemo bo betere le ho nepahala ha maemo le pheletso e ntlafalitsoeng ea bokaholimo. Slot le pocket milling hangata li baka mathata a ho ntša li-chip, haholo litsing tsa machining tse otlolohileng. Ho khaola li-chips hape ho ka baka ho hloleha ha leloala. Mohatsela o pholileng ka ho qetela o ntša li-chips sebakeng sa ho itšeha. Sena se felisa bothata kapa ho rema li-chips hape.

Likaroloana:

E loketse bakeng sa ho cheka tšepe, tšepe e sa hloekang, tšepe e entsoeng ka tšepe, thepa e se nang ferrous.

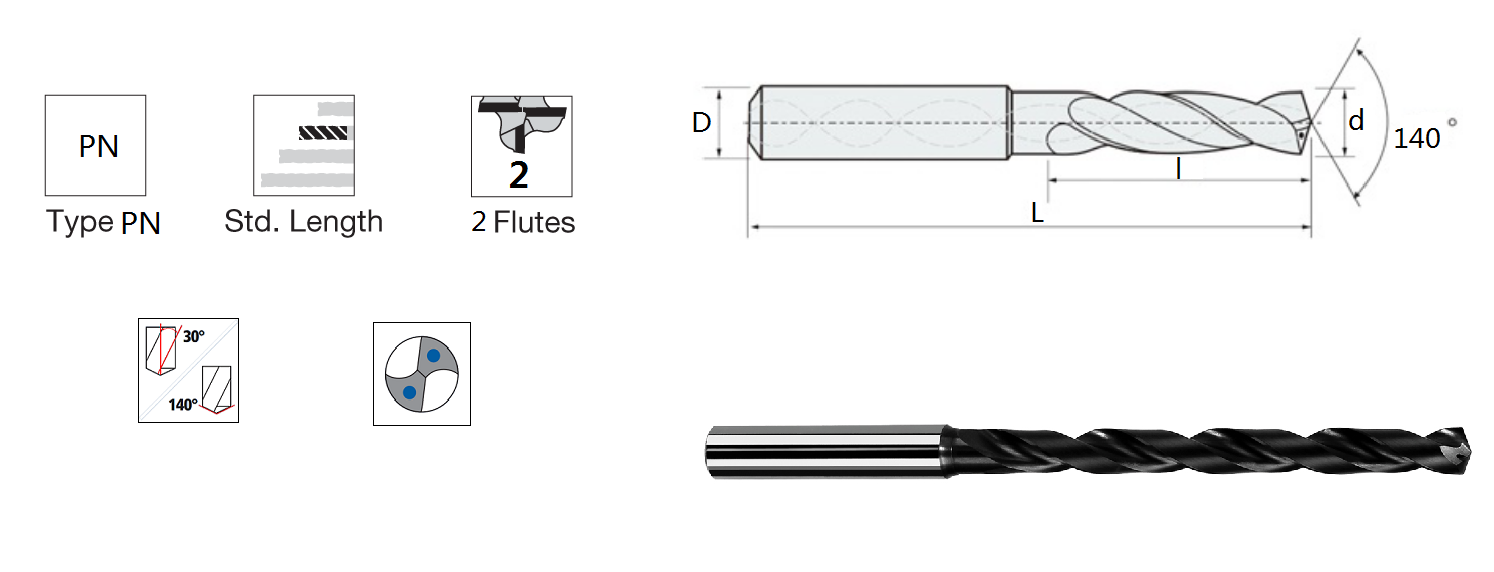

Stub chisel, bokhoni bo botle ba ho itšepa.

Radial point, khanyetso e nyane ea ho itšeha.

Lip chamfer, sekhahla sa phepelo e phahameng, ts'ebetso e phahameng.

Boholo bo tloaelehileng:

| Ho odara khouto | Kantle Bophara (D) | Bolelele ba Flute (l) | Kakaretso Bolelele (L) | Shank Diameter (D) |

| HJDK600-0500D | 5.00 | 28 | 66 | 6 |

| HJDK600-0510D | 5.10 | 28 | 66 | 6 |

| HJDK600-0520D | 5.20 | 28 | 66 | 6 |

| HJDK600-0550D | 5.50 | 28 | 66 | 6 |

| HJDK600-0555D | 5.55 | 28 | 66 | 6 |

| HJDK600-0580D | 5.80 | 28 | 66 | 6 |

| HJDK600-0600D | 6.00 | 28 | 66 | 6 |

| HJDK600-0610D | 6.10 | 34 | 79 | 8 |

| HJDK600-0620D | 6.20 | 34 | 79 | 8 |

| HJDK600-0630D | 6.30 | 34 | 79 | 8 |

| HJDK600-0650D | 6.50 | 34 | 79 | 8 |

| HJDK600-0660D | 6.60 | 34 | 79 | 8 |

| HJDK600-0680D | 6.80 | 34 | 79 | 8 |

| HJDK600-0690D | 6.90 | 34 | 79 | 8 |

| HJDK600-0700D | 7.00 | 34 | 79 | 8 |

| HJDK600-0710D | 7.10 | 41 | 79 | 8 |

| HJDK600-0740D | 7.40 | 41 | 79 | 8 |

| HJDK600-0750D | 7.50 | 41 | 79 | 8 |

| HJDK600-0780D | 7.80 | 41 | 79 | 8 |

| HJDK600-0800D | 8.00 | 41 | 79 | 8 |

| HJDK600-0810D | 8.10 | 47 | 89 | 10 |

| HJDK600-0840D | 8.40 | 47 | 89 | 10 |

| HJDK600-0850D | 8.50 | 47 | 89 | 10 |

| HJDK600-0860D | 8.60 | 47 | 89 | 10 |

| HJDK600-0870D | 8.70 | 47 | 89 | 10 |

| HJDK600-0880D | 8.80 | 47 | 89 | 10 |

| HJDK600-0900D | 9.00 | 47 | 89 | 10 |

| HJDK600-0930D | 9.30 | 47 | 89 | 10 |

| HJDK600-0950D | 9.50 | 47 | 89 | 10 |

| HJDK600-0960D | 9.60 | 47 | 89 | 10 |

| HJDK600-0980D | 9.80 | 47 | 89 | 10 |

| HJDK600-1000D | 10.00 | 47 | 89 | 10 |

| HJDK600-1025D | 10.25 | 55 | 102 | 12 |

| HJDK600-1040D | 10.40 | 55 | 102 | 12 |

| HJDK600-1050D | 10.50 | 55 | 102 | 12 |

| HJDK600-1060D | 10.60 | 55 | 102 | 12 |

| HJDK600-1080D | 10.80 | 55 | 102 | 12 |

| HJDK600-1100D | 11.00 | 55 | 102 | 12 |

| HJDK600-1120D | 11.20 | 55 | 102 | 12 |

| HJDK600-1150D | 11.50 | 55 | 102 | 12 |

| HJDK600-1180D | 11.80 | 55 | 102 | 12 |

| HJDK600-1200D | 12.00 | 55 | 102 | 12 |

| HJDK600-1225D | 12.25 | 60 | 107 | 14 |

| HJDK600-1250D | 12.50 | 60 | 107 | 14 |

| HJDK600-1270D | 12.70 | 60 | 107 | 14 |

| HJDK600-1275D | 12.75 | 60 | 107 | 14 |

| HJDK600-1280D | 12.80 | 60 | 107 | 14 |

| HJDK600-1300D | 13.00 | 60 | 107 | 14 |

| HJDK600-1310D | 13.10 | 60 | 107 | 14 |

| HJDK600-1350D | 13.50 | 60 | 107 | 14 |

| HJDK600-1380D | 13.80 | 60 | 107 | 14 |

| HJDK600-1400D | 14.00 | 60 | 107 | 14 |

| HJDK600-1425D | 14.25 | 65 | 115 | 16 |

| HJDK600-1450D | 14.50 | 65 | 115 | 16 |

| HJDK600-1475D | 14.75 | 65 | 115 | 16 |

| HJDK600-1480D | 14.80 | 65 | 115 | 16 |

| HJDK600-1500D | 15.00 | 65 | 115 | 16 |

| HJDK600-1510D | 15.10 | 65 | 115 | 16 |

| HJDK600-1550D | 15.50 | 65 | 115 | 16 |

| HJDK600-1580D | 15.80 | 65 | 115 | 16 |

| HJDK600-1600D | 16.00 | 65 | 115 | 16 |

Re ka hlahisa li-drill tsa 3D, 5D, 8D ho latela litlhoko tsa barekikapa li-drill tse sa tloaelehang joalo ka ha li etselitsoe.Re ka boela ra hlahisa litsila tse sa tloahelehang joalo ka ha li hlophisitsoe.

Sebopeho sa lisebelisoa:

1. Thepa ea 'Mele:

a. Ho thata ho feta kapa ho lekana le 92.8 HRA;

b. Boima bo boholo ho feta kapa bo lekana le 14.2g/cm³;

c. TRS e kholo ho feta kapa e lekana le 4200 N/mm²;

d. E lokolohile ka boemo ba ETA;

e. Ha ho silafatsoa ke lisebelisoa tse ling;

f. Porosity = A00/ B00 / C00 ;

g. Boholo ba lijo-thollo bo tšoanang le bo lumellanang. Ha ho boholo ba lijo-thollo bo ka bang kholo ho feta bo boletsoeng.

h. Chromium carbide grain growth inhibitor feela.

2. Lisebelisoa tsohle tsa tlhahiso, liphahlo li sebelisoa Jeremane, Switzerland, lisebelisoa tsa ho sebetsa;

3. It's proposed cutting less than 60HRC.

Ho roala:

Nano Coating AlTiN

Litšobotsi le Mosebetsi

1, Likahare tse phahameng tsa aluminium li fana ka boima bo matla bo chesang le ho hanyetsa oxidation.

2, Mokhoa o khethehileng o ntlafatsa sebopeho sa ho roala, botsitso bo ntlafalitsoeng haholo, bo fokotsa palo ea marotholi a holim'a metsi.

Tšebetso parameter:

| Mosebetsi oa workpeice | Ho poma | Sekhahla sa Fepa(mm/rev) | |||||||||

| lebelo | |||||||||||

| (m/mots) | |||||||||||

| Ka hare | D3 | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D18 | D20 | |

| phodiso | |||||||||||

| phunya | |||||||||||

| Tšepe ea k'habone, chip e telele | 14 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<125HB) | 100 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 60 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Tšepe ea khabone e tlase, e khuts'oane, | 140 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| tšepe e sehiloeng habonolo | 100 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<125HB) | 60 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Tšepe e phahameng ea carbon le bohareng | 120 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| carbon tšepe | 80 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<25HRC) | 60 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Tšepe ea motsoako, tšepe ea sesebelisoa | 110 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<35HRC) | 80 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Alloy steel,tool steel(35-48HRC) | 90 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| 60 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 | |

| 40 | 0.14 | 0.17 | 0.22 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| PH le ferritic, | 80 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| litšepe tsa martensitic | 50 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| (<35HRC) | 30 | 0.14 | 0.17 | 0.23 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 |

| Tšepe ea Austenitic stainless | 50 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.14 |

| (130-200HB) | 40 | 0.08 | 0.1 | 0.12 | 0.13 | 0.15 | 0.17 | 0.18 | 0.2 | 0.22 | 0.24 |

| 20 | 0.1 | 0.12 | 0.14 | 0.18 | 0.2 | 0.22 | 0.24 | 0.24 | 0.26 | 0.28 | |

| Matla a holimo austenitic le | 55 | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 |

| tšepe e sa hloekang e entsoeng | 40 | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 |

| (<25HRC) | 30 | 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 |

| Duplex tšepe e sa hloekang | 55 | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 |

| (<30HRC) | 40 | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 |

| 20 | 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | |

| Tshipi aena | 140 | 0.13 | 0.15 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 |

| (<32HRC) | 120 | 0.17 | 0.02 | 0.26 | 0.32 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | 0.48 |

| 60 | 0.21 | 0.26 | 0.32 | 0.4 | 0.42 | 0.46 | 0.5 | 0.52 | 0.54 | 0.56 | |

| Alloy aene ea bohare | 140 | 0.11 | 0.13 | 0.15 | 0.17 | 0.22 | 0.22 | 0.24 | 0.26 | 0.3 | 0.34 |

| bothata ba ho sebetsa, | 120 | 0.15 | 0.18 | 0.23 | 0.26 | 0.28 | 0.34 | 0.35 | 0.4 | 0.4 | 0.43 |

| nodular cast aine | 60 | 0.18 | 0.22 | 0.27 | 0.38 | 0.38 | 0.42 | 0.44 | 0.48 | 0.46 | 0.5 |

| (<28HRC) | |||||||||||

| Tšepe e sa khoneheng, | 100 | 0.06 | 0.08 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.23 | 0.23 |

| nodular cast aine | 90 | 0.09 | 0.1 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.28 | 0.29 |

| (<28HRC) | 60 | 0.11 | 0.13 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.34 | 0.35 |

| Aluminium alloy e entsoeng | 315 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 |

| (Si<12%) | 230 | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 |

| 90 | 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | |

| Etsa aluminium alloy | 315 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 |

| (Si<12%) | 230 | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 |

| 90 | 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | |

| Etsa aluminium alloy | 270 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 |

| (Si>12%) | 180 | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 |

| 90 | 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | |

| Motsoako oa koporo, oa koporo | 180 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 |

| (<200HB) | 135 | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 |

| 90 | 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | |

Tlhokomeliso:

Etsa bonnete ba hore peice ea mosebetsi le mochini li tsitsitse 'me li sebelisa sets'oants'o se nepahetseng, sebelisa li-chucks tsa hydraulic, li-collet chucks tsa boleng bo holimo.

Etsa bonnete ba hore kakaretso e bonts'itsoeng ea ho qeta (TIR) e ka tlase ho 0.02mm.

Boemo bo khothalletsoang ba ho itšeha bo loketse ho sebelisa metsi a qhibilihang.

Haeba boholo ba sesebelisoa bo le sieo tafoleng. Ka kopo sheba oteropo ea tafole ho khetho ea boholo ba lehare la bophara ba mekhahlelo ea ho itšeha, fetola litekanyo tsa ho itšeha ho latela maemo a sebele a ho sebetsa nakong ea ts'ebetso.

Khamphani e na le mohala o felletseng oa tlhahiso ea lisebelisoa tsa lehare ho tloha ho tokiso ea lihlahisoa tse tala, ho etsa hlobo, ho hatella, ho sila ka khatello, ho sila, ho roala le ho roala ka mor'a kalafo. E shebane le lipatlisiso le boqapi ba lisebelisoa tsa motheo, sebopeho sa groove, ho etsoa ka nepo le ho roala ka holim'a li-carbide NC, 'me e lula e ntlafatsa ts'ebetso ea machining, bophelo ba ts'ebeletso le lisebelisoa tse ling tsa ho itšeha tsa carbide NC inserts. Ka mor'a lilemo tse fetang leshome tsa lipatlisiso tsa saense le mekhoa e mecha, k'hamphani e tseba mekhoa e mengata ea motheo e ikemetseng, e na le R&D e ikemetseng le bokhoni ba ho qapa, 'me e ka fana ka tlhahiso e ikhethileng bakeng sa moreki e mong le e mong.