- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

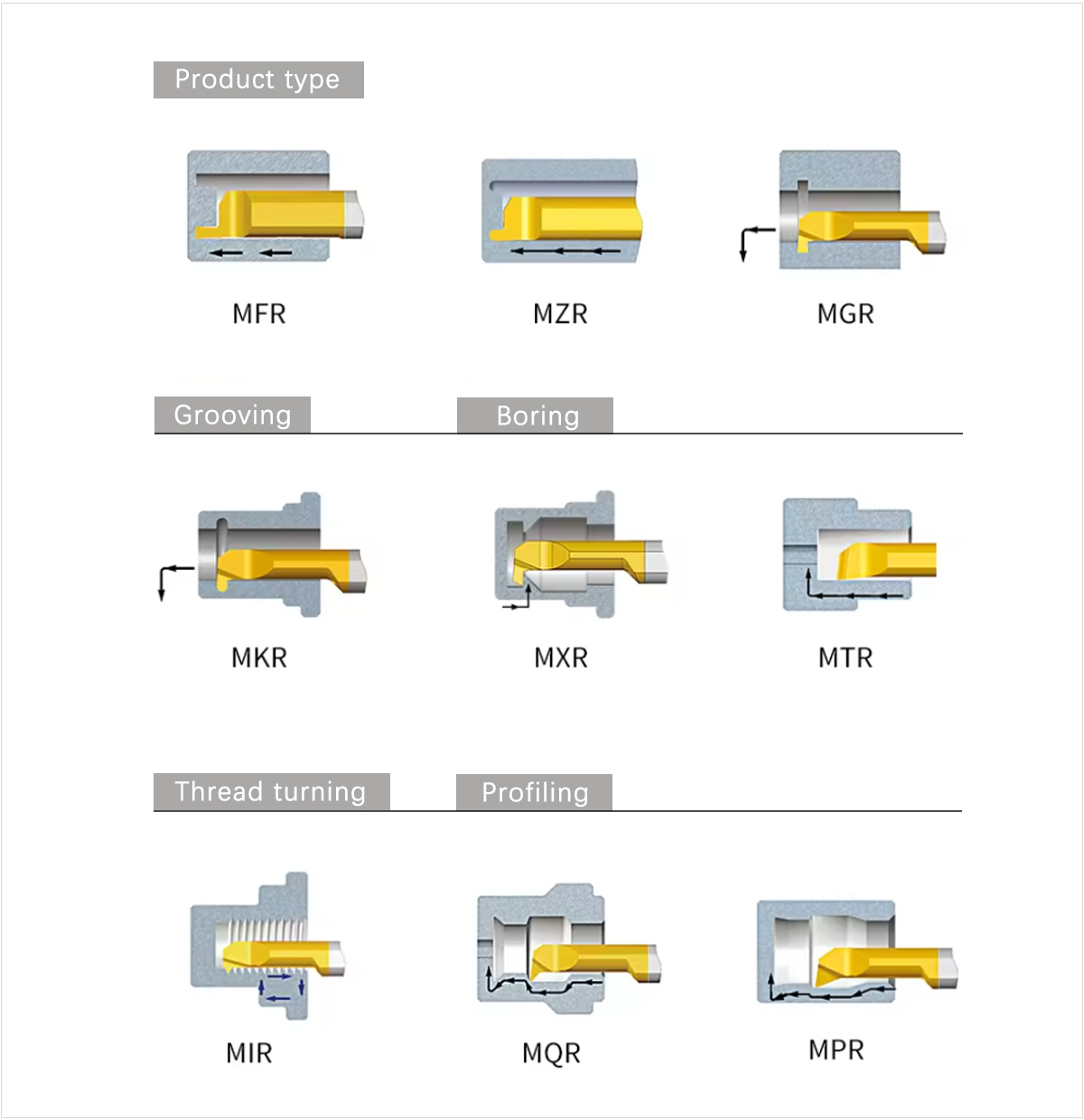

bophara bo nyane bo shebaneng le grooving bore cutter lathe standard boring bar tungsten carbide boring tools

tungsten carbide Face Grooving End Mill

CNC Boring ka hare ka Lisebelisoa tse Nyenyane tsa Diameter

sekotla se senyane se shebaneng le grooving bore cutter

sesebelisoa sa grooving ka hare ho lesoba le lenyenyane le fetolang sesebelisoa sa micro bore

| Tlhaloso | |||

| Ntho | Mill Diameter(mm) | LOC(mm) | Bolelele(mm) |

| MFR | 4 | B0.75 | 15 |

| MFR | 4 | B1 | 15 |

| MFR | 4 | B1.5 | 22 |

| MFR | 5 | B1 | 22 |

| MFR | 5 | B1.5 | 22 |

| MFR | 5 | B2 | 22 |

| MFR | 6 | B1 | 22 |

| MFR | 6 | B1.5 | 22 |

| MFR | 6 | B2 | 22 |

| MFR | 6 | B3 | 22 |

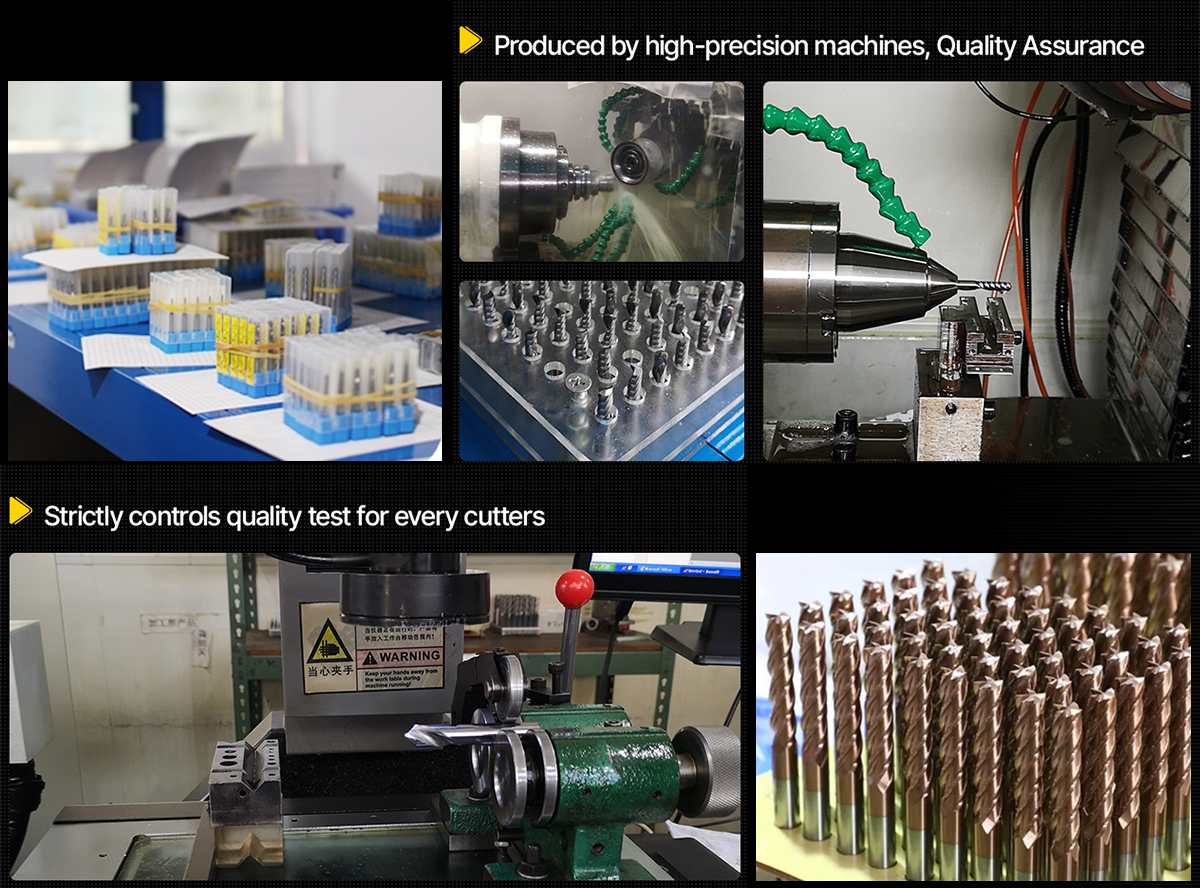

Melemo le litšobotsi tsa sehlahisoa:

1.Ts'ebetso eohle e amohela sesebelisoa sa mochini oa li-axis tse hlano bakeng sa ho sila ka nepo.Ho nepahala ho phahameng ha ther-angle ea ntlha ea sesebelisoa, le

moeli oa ho itšeha o boreleli tlas'a microscope makhetlo a 500.

2.Moqapi o sekametseng oa ho itšeha o etsa hore sehlahisoa se sebetsitsoeng se be boreleli le se bataletseng, se kentsoeng ka ntle ho grinder ea li-axis tse hlano ho netefatsa hore lisebelisoa li tsitsitse.

3.The Inner Hole End groove cutter ke sesebelisoa se sebelisoang machining, seo mosebetsi oa sona o ka sehloohong e leng ho phunya kapa ho sebetsana le lesoba le ka hare.

qetellong sefahleho. Ho na le mefuta e fapaneng ea eona, e tloaelehileng ke thipa ea groove e otlolohileng, thipa ea oblique groove, groove e tebileng.

thipa, thipa ea radius joalo-joalo. The otlolohileng grooved cutter ke mofuta o sebelisoang haholo.

Carbide ea setsebi Leloala la ho qetela Moetso:

Boholo (bo tloaelehileng le bo sa tloaelehang)

Tloaelo:

li-cutters tsa rona tse tloaelehileng tsa ho sila tsa carbide li koahela bophara bo fapaneng ho tloha ho 4mm ho isa ho 6mm ho kopana le machaba

taolo ya tlhahiso le maemo a boleng

E sa Tloaelehang:

Feme ea rona e ka etsa lihlahisoa tse sa tloaelehang ho latela setšoantšo sa theknoloji kapa lisampole.

Khamphani e na le mohala o felletseng oa tlhahiso ea lisebelisoa tsa lehare ho tloha ho tokiso ea lihlahisoa tse tala, ho etsa hlobo, ho hatella, ho sila ka khatello, ho sila, ho roala le ho roala ka mor'a kalafo. E shebane le lipatlisiso le boqapi ba lisebelisoa tsa motheo, sebopeho sa groove, ho etsoa ka nepo le ho roala ka holim'a li-carbide NC, 'me e lula e ntlafatsa ts'ebetso ea machining, bophelo ba ts'ebeletso le lisebelisoa tse ling tsa ho itšeha tsa carbide NC inserts. Ka mor'a lilemo tse fetang leshome tsa lipatlisiso tsa saense le mekhoa e mecha, k'hamphani e tseba mekhoa e mengata ea motheo e ikemetseng, e na le R&D e ikemetseng le bokhoni ba ho qapa, 'me e ka fana ka tlhahiso e ikhethileng bakeng sa moreki e mong le e mong.