- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

4/6 Flute Tungsten Carbide Reamer E nang le Customized

li-carbide tse tiileng tse otlolohileng

High Quality Solid Carbide Straight Shank Spiral Flute Reamer e tiileng ea carbide reamer

lisebelisoa tsa boleng bo holimo tsa CNC tsa ho itšeha HRC50 H7 2-12mm bophara ba carbide e otlolohileng reamer

Customized High Hardness Straight Shank Reamer Solid Carbide Reamer

Solid Carbide Reamer e nang le Phapang e Phahameng ka ho Fetisisa Bakeng sa Metal Machine

| Lebitso la lihlahisoa | Solid Carbide Reamer E otlolohile |

| Mantsoe a sehlooho | Carbide Straight Reamer |

| Shank Diameter: | 4-12 |

| E loketse bakeng sa | Aluminium, tšepe e entsoeng ka tšepe le tšepe |

| Nepahalo | Bonepe bo Phahameng |

| OEM | Amohela |

| Mantsoe a Sehlahisoa | cnc carbide otlolohile reamer, cnc ho itšeha lisebelisoa carbide reamer, hrc50 4-12mm customized carbide straight reamer |

Molemo oa Sehlahisoa:

E loketse ho sebelisoa ka har'a likoti kapa ka har'a likoti ntle le litšitiso tse kang keyways. (ka likoti li atoloha ka har'a sesebelisoa kaofela)

Ntlafatsa ho nepahala ha lesoba

Reamers e ntlafatsa ho nepahala le boleng ba lesoba ka ho seha le ho qeta ts'ebetso. E ka tlosa li-burrs, libopeho tse sa tloaelehang kapa boholo bo sa nepahaleng ka mekoting, ho etsa hore bokaholimo ba sekoti bo be boreleli le bo nepahetseng ka boholo.

Ntlafatsa ho pota-pota lesoba

Ho sebetsa ka mochini o sebetsang ho ka ntlafatsa ho pota-pota ha lesoba, ho etsa hore sebōpeho sa lesoba le be haufi le selikalikoe se loketseng. Sena ke sa bohlokoa bakeng sa mosebetsi oa kopano o hlokang ho lumellana le likarolo tse ling kapa o hloka ho nepahala ho phahameng.

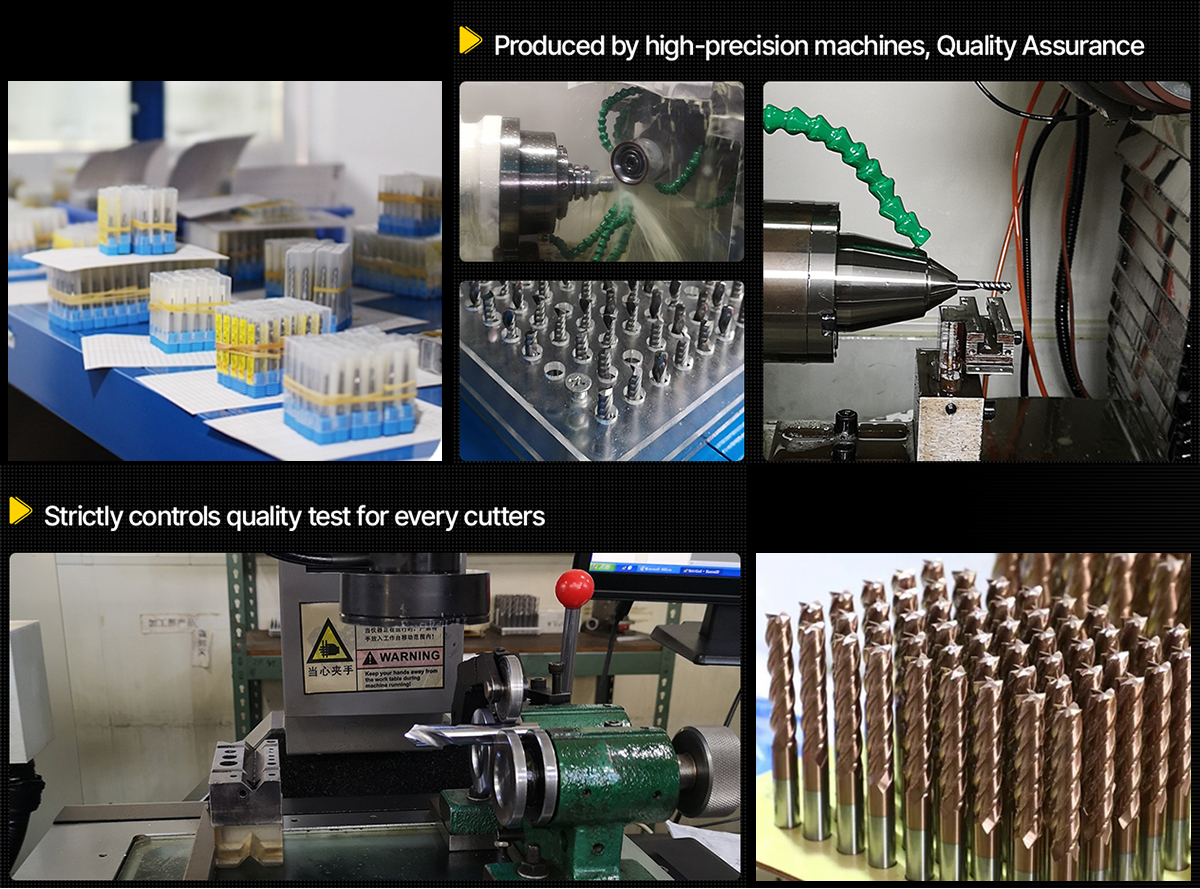

Professional Carbide End mill Manufacture

Boholo (bo tloaelehileng le bo sa tloaelehang)

Tloaelo:

li-cutters tsa rona tse tloaelehileng tsa ho sila tsa carbide li koahela bophara bo fapaneng ho tloha ho 4mm ho ea ho 12mm ho kopana le machaba

taolo ya tlhahiso le maemo a boleng

E sa Tloaelehang:

Feme ea rona e ka etsa lihlahisoa tse sa tloaelehang ho latela setšoantšo sa theknoloji kapa lisampole.

| Tlhaloso | |||||

| Mill Diameter(mm) | LOC(mm) | Shank Diameter(mm) | OAL(mm) | Flute No. | Bophahamo(mm) |

| 2 | 20 | 4 | 50 | 4F | 7 |

| 3 | 25 | 4 | 50 | 4F | 7 |

| 4 | 25 | 4 | 50 | 4F | 7 |

| 4 | 50 | 4 | 100 | 4F | 7 |

| 5 | 30 | 6 | 60 | 6F | 7 |

| 5 | 50 | 6 | 100 | 6F | 7 |

| 6 | 30 | 6 | 60 | 6F | 7 |

| 6 | 50 | 6 | 100 | 6F | 7 |

| 8 | 30 | 8 | 60 | 6F | 7 |

| 8 | 50 | 8 | 100 | 6F | 7 |

| 10 | 37.5 | 10 | 75 | 6F | 7 |

| 10 | 50 | 10 | 100 | 6F | 7 |

| 12 | 37.5 | 12 | 75 | 6F | 7 |

| 12 | 50 | 12 | 100 | 6F | 7 |

Khamphani e na le mohala o felletseng oa tlhahiso ea lisebelisoa tsa lehare ho tloha ho tokiso ea lihlahisoa tse tala, ho etsa hlobo, ho hatella, ho sila ka khatello, ho sila, ho roala le ho roala ka mor'a kalafo. E shebane le lipatlisiso le boqapi ba lisebelisoa tsa motheo, sebopeho sa groove, ho etsoa ka nepo le ho roala ka holim'a li-carbide NC, 'me e lula e ntlafatsa ts'ebetso ea machining, bophelo ba ts'ebeletso le lisebelisoa tse ling tsa ho itšeha tsa carbide NC inserts. Ka mor'a lilemo tse fetang leshome tsa lipatlisiso tsa saense le mekhoa e mecha, k'hamphani e tseba mekhoa e mengata ea motheo e ikemetseng, e na le R&D e ikemetseng le bokhoni ba ho qapa, 'me e ka fana ka tlhahiso e ikhethileng bakeng sa moreki e mong le e mong.