- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

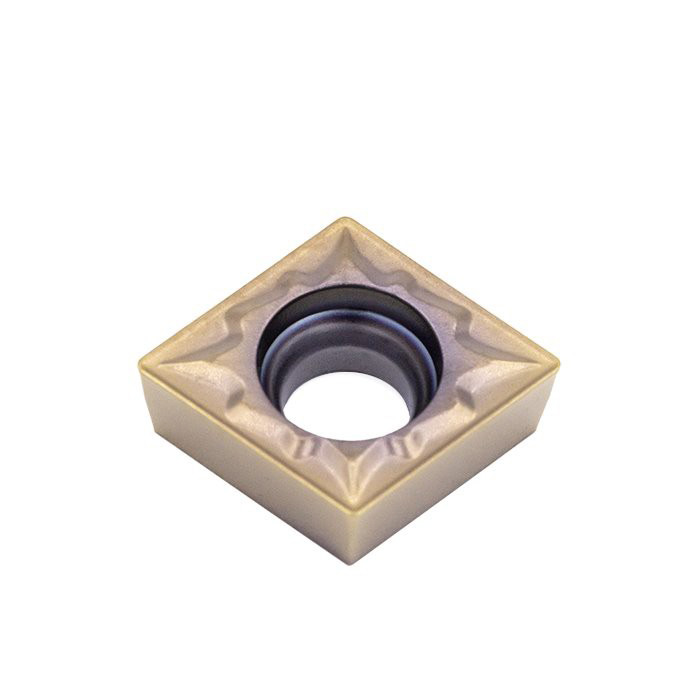

CCMT Insets

CCMT Insets

Lebitso la sehlahisoa: CCMT Insets

Letoto: CCMT

Li-Chip-Breaker: JW/MM

Lintlha tsa Sehlahisoa:

CCMT carbide kenya ke daemane ea 80 ° e nang le liphallelo tsa 7 °. Sekoti se bohareng ke sekontiri se le seng sa 40 ° -60 °, le sekheo sa chip se nang le lehlakore le le leng. E na le ts'ireletso e phahameng le ts'epahalo bakeng sa machining ea sefahleho sa ho qetela tlas'a mosebetsi o boima o sitisoe ke ho itšeha, ho sisinyeha le maemo a sa tsitsang, 'me ke sesebelisoa se loketseng bakeng sa machining workpiece surfaces maemong a thata. Ho phaella moo, CCMT e na le melemo ea ho nepahala ho phahameng, ho hanyetsa ho roala, ho hanyetsa kutu, bophelo bo bolelele ba tšebeletso.

Litlhaloso:

| Kopo | Mofuta | Ap (mm) | Fn (mm/rev) | Kereiti | ||||||||||

| CVD | PVD | |||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK4335 | JK1025 | JK1325 | JK1525 | JK1328 | JR1525 | JR1010 | ||||

Kakaretso Semi Finishing | CCMT060204-JW | 0.40-2.10 | 0.05-0.18 | • | O | • | O | O | • | O | O | |||

CCMT060208-JW | 0.80-2.10 | 0.10-0.35 | • | O | • | O | O | • | O | O | ||||

CCMT09T304-JW | 0.40-3.80 | 0.05-0.18 | • | O | • | O | O | • | O | O | ||||

CCMT09T308-JW | 0.80-3.20 | 0.10-0.35 | • | O | • | O | O | • | O | O | ||||

CCMT120404-JW | 0.40-4.30 | 0.05-0.18 | • | O | • | O | O | • | O | O | ||||

CCMT120408-JW | 0.80-4.30 | 0.10-0.35 | • | O | • | O | O | • | O | O | ||||

CCMT120412-JW | 1.20-4.30 | 0.15-0.55 | • | O | • | O | O | • | O | O | ||||

• : Kereiti e khothaletsoang

O: Kereiti ya boikgethelo

| Kopo | Mofuta | Ap (mm) | Fn (mm/rev) | Kereiti | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK4235 | JK4335 | JK1025 | JK1325 | JK1525 | JK1328 | JR1525 | JR1010 | ||||

M Ho qetela | CCMT060204-MM | 0.30-1.60 | 0.05-0.15 | • | O | • | O | ||||||||

CCMT060208-MM | 0.60-1.60 | 0.10-0.30 | • | O | • | O | |||||||||

CCMT09T304-MM | 0.30-2.20 | 0.05-0.15 | • | O | • | O | |||||||||

CCMT09T308-MM | 0.60-2.40 | 0.10-0.30 | • | O | • | O | |||||||||

• : Kereiti e khothaletsoang

O: Kereiti ya boikgethelo

Kopo:

CCMT e sebelisoa ka ho pharaletseng ha ho seha le ho betla, ho fetola khoele, joalo-joalo Ke khetho e ntle e ntle bakeng sa ho etsa roughing.semi-finishing.finishing.general machining of steel. tšepe e sa hloekang le tšepe e entsoeng ka tšepe.

Khamphani e na le mohala o felletseng oa tlhahiso ea lisebelisoa tsa lehare ho tloha ho tokiso ea lihlahisoa tse tala, ho etsa hlobo, ho hatella, ho sila ka khatello, ho sila, ho roala le ho roala ka mor'a kalafo. E shebane le lipatlisiso le boqapi ba lisebelisoa tsa motheo, sebopeho sa groove, ho etsoa ka nepo le ho roala ka holim'a li-carbide NC, 'me e lula e ntlafatsa ts'ebetso ea machining, bophelo ba ts'ebeletso le lisebelisoa tse ling tsa ho itšeha tsa carbide NC inserts. Ka mor'a lilemo tse fetang leshome tsa lipatlisiso tsa saense le mekhoa e mecha, k'hamphani e tseba mekhoa e mengata ea motheo e ikemetseng, e na le R&D e ikemetseng le bokhoni ba ho qapa, 'me e ka fana ka tlhahiso e ikhethileng bakeng sa moreki e mong le e mong.