- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

1/4 6mm 6mm Shank Carving Cutting Ho sila Lisebelisoa tsa ho phunya

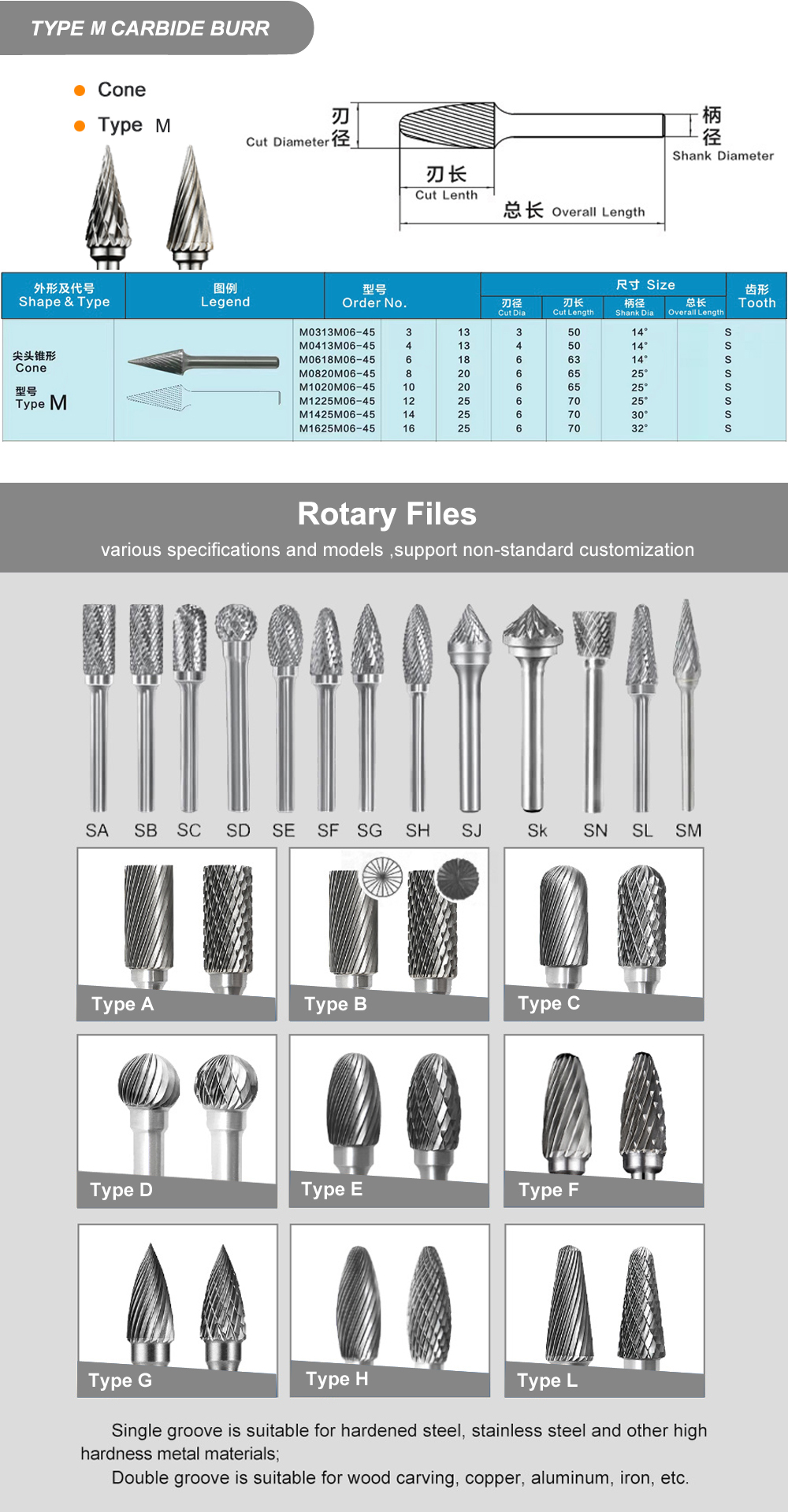

M mofuta oa lifaele tsa rotary

Shank Diameter: 1/4", 1/8" ,1/2" 3 ,6, 8 mm

Chipbreaker: Single/Double/Aluma/Diamond Cut

Mosebetsi: tšepe, tšepe ea tšepe, tšepe ea carbon, tšepe ea motsoako, tšepe e sa hloekang, aluminium ea koporo, joalo-joalo.

Tšebeletso: OEM & ODM

Tlhaloso ea Sehlahisoa

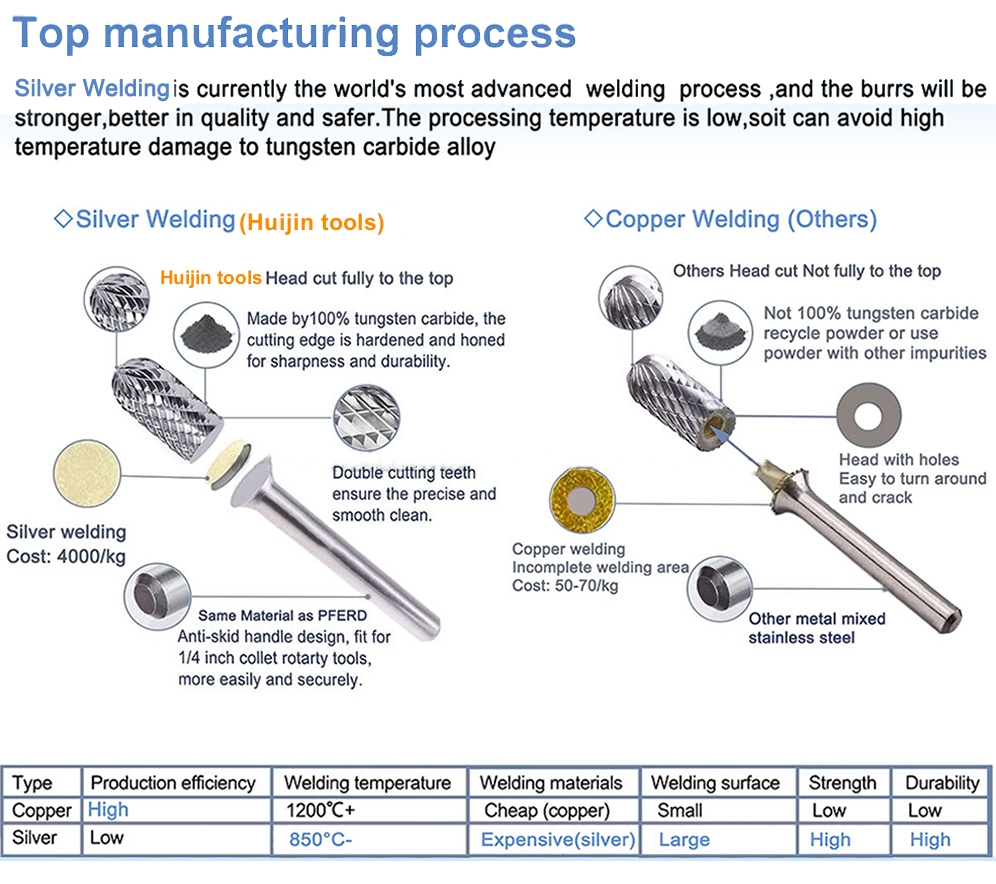

Boitsebiso: 100% ea lisebelisoa tse tala.

Mamello: taolo e tiileng ea ho mamella tekanyo, e ka fihlang +/-0.01mm;

Mephato: tse fapaneng bakeng sa khetho: YG6, YG8, YG8C, YG11C,YG15C joalo-joalo.

Mefuta: standard, conical, parabolic, ballistic

Ts'ebetso ea 'mele: boima bo phahameng le boima ba tšusumetso, botsitso bo botle haholo ba mochini le lik'hemik'hale.

kopo ea sehlahisoa

Faele e entsoeng ka samente ea carbide rotary e sebelisoa haholo mochining, likoloing, likepeng, indastering ea lik'hemik'hale, ho betla mesebetsi ea matsoho le likarolo tse ling tsa indasteri, ka phello e makatsang. Lisebelisoa tsa eona tse kholo ke:

-- Fine machining tse fapa-fapaneng hlobo metal cavities.-- Mefuta eohle ea tšepe, e seng tšepe e betla, le ho betla limpho tsa mesebetsi ea matsoho.

--Hloekisa flash, burr le weld of castings, forgings and weldments

--Chamfering, rounding le groove process ea likarolo tse fapaneng tsa mochini, ho hloekisa liphaephe, le ho phethela bokaholimo ba masoba a kahare a likarolo tsa mochini.

-- Ho benya ha semathi sa impeller.

Taolo ea boleng:

1.Lisebelisoa tsohle tse tala li lekoa ho latela boima, boima le TRS pele li sebelisoa

2.Sehlahisoa se seng le se seng se feta nakong ea ts'ebetso le tlhahlobo ea ho qetela

3.Sehlahisoa se seng le se seng se ka lateloa

Ts'ebetso ea tlhahiso le ho phethoa ha carbide e entsoeng ka samente

Metal W\C Powder:Phofo e phahameng ea tungsten e sebelisoa e le thepa e tala.

Motsoako o itokisang:The rolling ball mill makesthe powder ingredients homogenize.The surface area of the powder is added and the particle surface is increase.Can eketsa le ho khothalletsa sintering.

Ho omisa seretse ka setlolo:Tokisetso ea metsoako e sebelisoa sebakeng se koetsoeng.Tsireletso e phahameng ea naetrojene, phokotso e sebetsang ea ho itokisa.Ka mokhoa ona, motsoako o ka eketsa oksijene, 'me o ka.Ho netefatsa bohloeki ba lintho tse bonahalang le ho thibela lintho tse bonahalang.The ditshila.

Ho etsa compression:Ho sebelisa mokhoa oa mochine oa khatello ea static, e sebetsang hantle ea du.Absolute hatello ea liphoso, boima bo phahameng.esita le.

Ho etsa degumming le pele ho chesa halofo ea tlhahlobo

Vacuum low pressure sintering:Thermostatic sintering Khatello e phahameng ea sintering e ka fihla lik'hilograma tse 100. Ho tlosoa ha lesoba le setseng ka motsoako ho fokotsehile.Ho phaella moo, e kopane haholo ebile e ntle.Degree, alloy alloy e phahameng e se nang letho.Taolo e tsoetseng pele, Sisteme ea mocheso e ka fokotsa ka katleho poleiti e thata ea alloy. Monyetla oa ho fetoha ha boleng ho etsahala.

Ho omisa ka halofo, lihlahisoa tse se nang letho tsa carbide

Mechine e nepahetseng ea litsebi

Ho na le mefuta e mengata ea mekhoa ea machining bakeng sa mochini o nepahetseng oa carbide. Joalo ka EDM, ho seha terata butle, CNC milling, CNC lathe process, joalo-joalo.

komporo ea ronaefe kapa efe ke moetsi ea hloahloa oa carbide e entsoeng ka samente e kopanyang tlhahiso le machining e nepahetseng. Khamphani e na le lisebelisoa tse tsoetseng pele tsa tlhahiso le lisebelisoa tse kang ho fetola le ho sila setsi sa machining, setsi sa machining sa li-axis tse hlano, setsi sa machining sa li-axis tse 'ne, mochini oa CNC o boreleli le mochini o silang, ho phunya lesoba le tebileng, ho bora le ho honing, sebōpi sa vacuum sintering, terata. ho itšeha, joalo-joalo Ho sebetsa matla a ho tšehetsa. E na le matla a matla haholo machining a nepahetseng a carbide e entsoeng ka samente, 'me e na le lisebelisoa tse fapaneng tse tsoetseng pele tsa machining, tse loketseng machining a mefuta e fapaneng ea boleng bo holimo, lisebelisoa tse khethehileng, sebopeho se kahare sa eccentric, litsoe le likarolo tse rarahaneng tsa geometri.

Tlhahlobo e tsoetseng pele le lisebelisoa tsa tlhahlobo

Huijin e na le lisebelisoa tse tsoetseng pele tsa tlhahlobo le tlhahlobo, joalo ka: mohlahlobi oa carbon sulfur, tester ea TRS, microscope ea metallographic, coercivity tester, cobalt magnetic tester, Rockwell hardness tester, Vickers hardness tester, drop tester, micrometer, roundness tester, ultrasonic scanner, joalo-joalo. ., ts'ebetso e 'ngoe le e' ngoe e ka beoa leihlo ka nepo ho netefatsa sekhahla se tšoanelehang sa lihlahisoa.

Tlhahlobo ea thepa e tala: sebelisa carbon-sulfur analyzer ho fumana hore na lik'hemik'hale tsa tungsten carbide powder lia tšoaneleha.

Ka mor'a ho sintering, sebelisa sesebelisoa ho hlahloba thepa: hlahloba TRS, microstructure, cobalt content, ho thatafala ha thepa, molamu oa carbide o entsoeng ka samente le teko ea ho theoha ho netefatsa hore ha ho na sekoli se bohareng ka hare ho thepa, hlobo e entsoeng ka carbide e se nang letho, eketsa ultrasonic. scanner ho qoba lehlabathe Hole ka hare ho sekheo.

Tlhahlobo ea thepa ea matsoho ka mor'a ho sintering: Tlhahlobo ea pono ea mefokolo ea thepa ke basebetsi ba nang le tsebo, ho kenyelletsa le carburization le decarburization, masoba a lehlabathe le ka holim'a metsi, mapetsong a manyenyane.

Chekeha ka mor'a ho cheka: Lekola boholo ka micrometer, 'me bakeng sa lithupa tsa carbide, eketsa tlhahlobo ea ho pota-pota.

Litsela tsa thomello/ Ho paka

-Lik'hamphani tsa Express: DHL, FedEx, TNT, UPS, joalo-joalo.

-Lifofane.

-Sekepe sa leoatle

A. Standard paka

-Mabokose a polasetiki a nang le foam ka hare le lebokose ka ntle.

-Mabokose a pampiri a nang le foam ka hare le lebokose ka ntle.

-Mabokose a ka hare / thepa ea ho paka ka hare le lebokose la plywood ka ntle (bakeng sa sehlahisoa se boima)

Khamphani e na le mohala o felletseng oa tlhahiso ea lisebelisoa tsa lehare ho tloha ho tokiso ea lihlahisoa tse tala, ho etsa hlobo, ho hatella, ho sila ka khatello, ho sila, ho roala le ho roala ka mor'a kalafo. E shebane le lipatlisiso le boqapi ba lisebelisoa tsa motheo, sebopeho sa groove, ho etsoa ka nepo le ho roala ka holim'a li-carbide NC, 'me e lula e ntlafatsa ts'ebetso ea machining, bophelo ba ts'ebeletso le lisebelisoa tse ling tsa ho itšeha tsa carbide NC inserts. Ka mor'a lilemo tse fetang leshome tsa lipatlisiso tsa saense le mekhoa e mecha, k'hamphani e tseba mekhoa e mengata ea motheo e ikemetseng, e na le R&D e ikemetseng le bokhoni ba ho qapa, 'me e ka fana ka tlhahiso e ikhethileng bakeng sa moreki e mong le e mong.