Tungsten carbide, eo hape e tsejoang e le cemented carbide, ke thepa e batlang e le ea bohlokoa haholo lits'ebetsong tse ngata tsa tlhahiso. Mekhoa e mengata ea machining ea tšepe e sebelisa lisebelisoa tsa tungsten carbide e le malebela a lisebelisoa, kaha carbide e entsoeng ka samente e na le thepa e thata haholo le e thibelang mocheso e loketseng ho cheka, ho bora, ho bōpa le ho etsa lisebelisoa tsa tšepe. Li-mill tse ngata tsa sejoale-joale tsa sefahleho, lisebelisoa tsa lathe le li-mill tsa ho qetela li sebelisa lisebelisoa tsena tsa ho itšeha.

Lisebelisoa tsa Tungsten Carbide li etsoa joang?

Mabenkele a ho etsa thepa le a machining a itšetlehileng ka li-tungsten carbide tse kentsoeng bakeng sa lisebelisoa tsa lebelo le holimo hangata a feta liketeng tsa likepe selemo se seng le se seng. Basebelisi ba mochini ba sebetsa ka lisebelisoa tse ngata letsatsi le leng le le leng, ba itšetlehile ka motsoako oa bona o rarahaneng oa k'hemistri le geometry ho fana ka likarolo tse hlokahalang bakeng sa tlhahiso e nepahetseng, e lebelo le phahameng. Ho utloisisa hore na ho kenngoa ha carbide ho etsoa joang le hore na mekhoa ea ho kenya letsoho e ama bokhoni ba bona joang ho ka thusa basebetsi ba mechine le bahlahisi ho utloisisa lisebelisoa tsa bona le mekhoa ea bona ka kakaretso.

Lisebelisoa tsa tungsten carbide li na le carbide e entsoeng ka samente, e entsoeng ka motsoako oa cobalt le tungsten carbide. Likaroloana tse thata tsa Tungsten carbide ka har'a ho kenya li fana ka kenyelletso ka litšoaneleho tsa eona tsa ho thatafala, 'me cobalt e sebetsa e le ntho e tlamang, e tšoereng thepa e tiileng hammoho. Boholo ba lithollo tsa tungsten tse sebelisoang li ama boima ba ho kenya; lithollo tse khōloanyane (3-5 li-micron) li etsa hore ho be le lisebelisoa tse kentsoeng tse bonolo, tse aparang ka potlako, ha lithollo tse nyenyane (tse ka tlaase ho 1 micron) li etsa hore ho be le li-inserts tse thata ka ho fetisisa, tse kenngoeng ka thata. Ha ho kenngoa ka thata, ho tla ba le brittle haholoanyane. Ha ho etsoa litšepe tse thata ka tsela e ikhethang, ho sebelisoa lintho tse thata ho feta tse nang le lithollo tse nyane, athe tse bonolo li sebelisoa hangata mekhoeng ea ho etsa machining e nang le likheo tse khaotsoeng, tse hlokang hore ho se ke ha e-ba le lisebelisuoa tse senyehileng le tse thata. Karo-karolelano ea cobalt ho tungsten carbide e boetse e susumetsa maemo a thata a ho kenya carbide; cobalt e bonolo haholoanyane, kahoo ha cobalt e kenngoa ka ho eketsehileng, e tla ba bonolo haholoanyane.

Moenjiniere oa Tungsten carbide kenya o entse qeto ea hore na ke boemo bofe ba boima bo lokelang ho finyelloa; ts'ebetso ea tlhahiso e qala ka thepa e tala ea phofo. Tungsten e phofshoana, cobalt le k'habone lia siloa ebe li kopanngoa le joala le metsi, 'me li etsa seretse se teteaneng. Ntho ena e kenngoa ka har'a se omisang metsi, e leng mouoane, e siea phofo e tsoakiloeng ka ho feletseng. Li-carbide tse kenyang li kenngoa ka mokhoa oa sintering moo li kopantsoeng le polymer ho etsa pente, li hatelloa ka har'a likotoana tse nang le sebōpeho sa ho kenya ebe li kenngoa ka sebōping se chesang se chesang hore se chesoe. Polymer e qhibilihisoa ka ntle ho ho kenngoa nakong ea mohato ona, 'me ho kenngoa ho fokotseha.

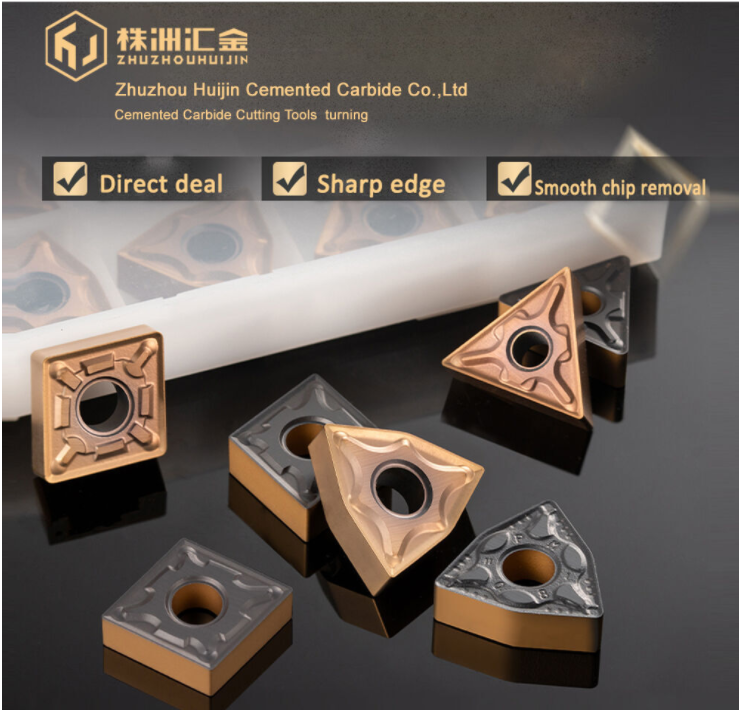

Lisebelisoa tsa ho seha tsa Tungsten carbide ke lihokelo tse ka nkeloang sebaka bakeng sa lisebelisoa tsa ho seha tseo hangata li nang le mothati oa sebele. Lisebelisoa tsa lisebelisoa tsa ho itšeha li kenyelletsa boring, kaho, cutoff le karohano, ho cheka, grooving, hobbing, milling, mining, sawing, kuta le ho itšeha, ho tlanya, ho thaepa, ho reteleha, le ho phethoha ha brake rotor.

Poso: 2023-10-26