Tlhahlobo ea sebopeho sa li-carbide tse kentsoeng ka samente

Joalo ka lihlahisoa tsohle tse entsoeng ke batho, ho etsoa ha mahare a tšepe a tšepe a tlameha ho qala ho rarolla bothata ba lisebelisoa tse tala, ke hore, ho tseba sebopeho le foromo ea lisebelisoa tsa lehare. Boholo ba li-blades tsa kajeno li entsoe ka carbide e entsoeng ka samente, eo haholo-holo e entsoeng ka tungsten carbide (WC) le cobalt (Co). WC ke karoloana e thata ka har'a lehare, 'me Co e ka sebelisoa e le setlamo ho bopa lehare.

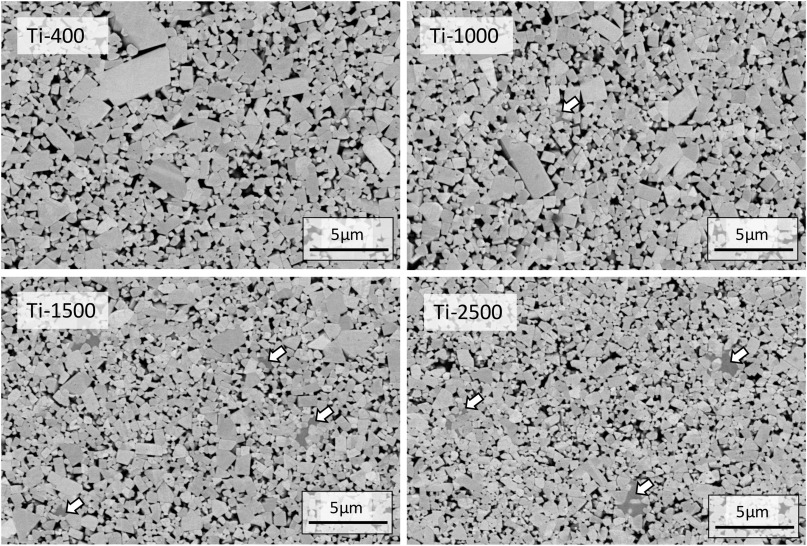

Tsela e bonolo ea ho fetola thepa ea carbide e entsoeng ka samente ke ho fetola boholo ba lijo-thollo tsa likaroloana tsa WC tse sebelisitsoeng. Boholo ba likaroloana tse kholo (3-5 μ m) Ho thatafala ha thepa ea carbide e entsoeng ka samente e lokiselitsoeng ke likaroloana tsa WC e nang le C% e tlaase ebile e bonolo ho apara; Likaroloana tsa WC tse nyane (< 1 μ m) li ka hlahisa lisebelisoa tse thata tsa alloy tse nang le boima bo phahameng, ho hanyetsa ho apara hantle, empa hape le brittleness e kholoanyane. Ha ho etsoa lisebelisoa tsa tšepe tse nang le boima bo phahameng haholo, tšebeliso ea lijo-thollo tse ntle tse kentsoeng ka carbide e ka finyella liphello tse ntle tsa mochine. Ka lehlakoreng le leng, sesebelisoa sa carbide se nang le lijo-thollo tse mahoashe se na le ts'ebetso e ntlafetseng ea ho itšeha nako le nako kapa mochini o mong o hlokang ho tiea ho hoholo ha sesebelisoa.

Tsela e 'ngoe ea ho laola litšobotsi tsa li-carbide tse kentsoeng ke ho fetola karolo ea WC ho Co content. Ha ho bapisoa le WC, ho thatafala ha Co ho tlase haholo, empa ho thatafala ho molemo. Ka hona, ho fokotsa litaba tsa Co ho tla fella ka lehare le phahameng le thata. Ha e le hantle, sena se boetse se hlahisa bothata ba ho leka-lekanya ho feletseng - li-blades tse thata tse phahameng li na le khanyetso e ntle ea ho apara, empa brittleness ea bona le eona e kholoanyane. Ho latela mofuta o ikhethileng oa ho sebetsa, ho khetha boholo bo nepahetseng ba lijo-thollo tsa WC le karolelano ea litaba tsa Co ho hloka tsebo e nepahetseng ea mahlale le boiphihlelo bo bongata ba ho sebetsa.

Ka ho sebelisa theknoloji ea thepa ea gradient, ho sekisetsa pakeng tsa matla le ho tiea ha lehare ho ka qojoa ho isa bohōleng bo itseng. Theknoloji ena, e 'nileng ea sebelisoa haholo ke baetsi ba lisebelisoa tse kholo tsa lefats'e, e kenyelletsa tšebeliso ea tekanyo e phahameng ea Co content lera le ka ntle la lehare ho feta lehare le ka hare. Ka ho khetheha, karolo e ka ntle ea lehare (botenya ba 15-25 μ m) Eketsa Co content ho fana ka ts'ebetso e ts'oanang le "buffer zone", e le hore lehare le ka mamella tšusumetso e itseng ntle le ho phunyeha. Sena se nolofalletsa 'mele oa sesebelisoa oa lehare ho fumana thepa e fapaneng e ntle e ka finyelloang feela ka ho sebelisa carbide e entsoeng ka samente e nang le matla a phahameng.

Hang ha boholo ba likaroloana, sebopeho le likarolo tse ling tsa tekheniki tsa lisebelisoa tse tala li khethiloe, mokhoa oa sebele oa ho etsa lihlahisoa oa ho itšeha o ka qala. Ntlha ea pele, kenya phofo ea tungsten e ts'oanang, phofo ea carbon le phofo ea cobalt ka har'a leloala le batlang le lekana le mochine oa ho hlatsoa, sila phofo ho isa tekanyong e hlokahalang, 'me u kopanye mefuta eohle ea thepa ka ho lekana. Nakong ea ts'ebetso ea ho sila, joala le metsi li kenngoa ho lokisa slurry e teteaneng e ntšo. Ebe slurry e kenngoa ka har'a se omisang leholiotsoana, 'me mokelikeli o ka har'a slurry o fetoha mouoane ho fumana phofo ea lumpy le ho bolokoa.

Ts'ebetsong e latelang ea ho itokisa, mohlala oa lehare o ka fumanoa. Ntlha ea pele, phofo e lokiselitsoeng e kopantsoe le polyethylene glycol (PEG). Joaloka polasetiki, PEG e ka kopanya phofo ka nakoana joalo ka hlama. Thepa e ntan'o hatelloa hore e be sebopeho sa lehare ka har'a thapo. Ho latela mekhoa e fapaneng ea ho hatisa lehare, mochini o hatisang o le mong o ka sebelisoa bakeng sa ho tobetsa, kapa mochini oa khatiso oa multi axis o ka sebelisoa ho hatella sebopeho sa lehare ho tsoa likhutlong tse fapaneng.

Ka mor'a ho fumana sekheo se hatisitsoeng, se kenngoa ka sebōping se seholo sa sintering 'me se chesoa ka mocheso o phahameng. Ts'ebetsong ea sintering, PEG e qhibilihisoa ebe e ntšoa ka har'a motsoako oa billet, e siea lehare la carbide le entsoeng ka halofo le felileng. Ha PEG e qhibilihisoa, lehare le honyela ho fihlela * boholo ba lona ba ho qetela. Mohato ona oa ts'ebetso o hloka lipalo tse nepahetseng tsa lipalo, hobane ho fokotseha ha lehare ho fapane ho ea ka lihlopha tse fapaneng tsa thepa le likarohano, 'me mamello ea tekanyo ea sehlahisoa se phethiloeng e hlokeha ho laoloa ka har'a li-microns tse' maloa.

Poso: 2023-01-15