- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

HJDK650 Tungsten carbide leylisyada xarunta

Tababarka xarunta carbide Tungsten

HJDK650 Tungsten carbide leylisyada xarunta

Ku habboon qodista birta, birta aan lahayn, birta shubka ah, walxo aan birta ahayn.

Adag HRA92.8

Waxyaabaha: tungsten carbide

HJDK650 Taxanaha-xarunta

Odhaah suugaaneed:

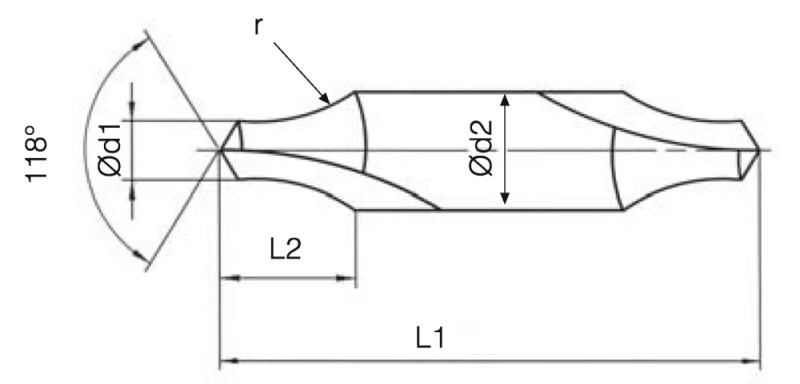

Daloolinta xarunta HJDK650 waxay xaqiiqsanaysaa isku darka wanaagsan ee u dhexeeya socodka chip-ka ee qaybta qodista iyo tan qaybta countersink. Fuulooyinkoodu waxay si buuxda u dabooli karaan jajabyada waxayna si fiican u shaqeeyaan si ay u saaraan chips.Center waxay leeyihiin geesaha goynta ee labada daraf, waxayna leeyihiin biibiile wareeg ah. xoogga, waxaan yareynay dhererka dhererka. Intaa waxaa dheer si loo magdhabo daciifnimada barta isku xirka ee u dhaxaysa laylinta iyo countersink, barta isku xidha waxay leedahay R kaas oo raadiyaha ku dhex jira taper-ka dambe ee layliga. Waxay kaloo leeyihiin saf ballaaran.

Astaamaha:

Ku habboon qodista birta, birta, birta, wax aan birta ahayn.

Stub chisel, karti is-xakameyn heer sare ah.

Barta shucaaca, iska caabbinta goynta yar.

Farsamaynta bishimaha, heerka quudinta sare, waxtarka sare.

Cabbirka caadiga ah:HJDK650 Taxane Qalliinka Xarunta Budada Fiican

| Dalbashada koodka | Dhexroorka | Xagasha | Dhererka hargabka | O.A.L. | Shank Dia. |

| HJDK650-0102 | 1 | 60° | 1.5 | 35 | 4 |

| HJDK650-0202 | 2 | 60° | 2.5 | 50 | 5 |

| HJDK650-0252 | 2.5 | 60° | 3 1 | 60 | 6.3 |

| HJDK650-03152 | 3.15 | 60° | 3.9 | 70 | 8 |

| HJDK650-0402 | 4 | 60° | 5 | 80 | 10 |

| HJDK650-0502 | 5 | 60° | 6.3 | 80 | 12 |

| HJDK650-0632 | 6.3 | 60° | 80 | 80 | 16 |

Qalab ka kooban:

1.Guryaha Jirka:

A) Adag ka weyn ama la mid ah 92.8 HRA;

B) Cufnaanta ka weyn ama la mid ah 14.2 g/cm³;

C) TRS ka weyn ama la mid ah 4200 N/mm²;

D) Xor ka ah xaaladda marxaladda ETA;

E) Wax wasakhayn ah oo alaabta kale;

F) Porosity = A00 / B00 / C00 ;

G) Cabbirka badarka lebbisan oo joogto ah. Ma jiro cabbir hadhuudh ah oo ka weyn kara inta la cayimay.

H) Chromium kaarbiid ka hortag koritaanka hadhuudhka oo keliya.

2.Dhammaan qalabka wax soo saarka, dahaarka waxaa loo isticmaalaa gudaha Germany, Switzerland, qalabka habaynta;

Qiyaasta hawlgalka:

| Halbeegga hawlgalka qoditaanka xarunta: | ||||||||||

| Shayga Workpeice | Xawaaraha goynta | Heerka quudinta (mm/rev) | ||||||||

| (m/min) | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D20 | ||

| Low carbon steel, long chip (<125HB) | 130 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.15 | 0.17 | 0.2 | 0.24 | 0.26 | 0.3 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.26 | 0.3 | 0.32 | 0.35 | 0.4 | 0.45 | ||

| Bir kaarboon hooseeya, jeexan gaaban, fudud bir gooyay ( | 120 | 0.1 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.24 | 0.3 | 0.32 | 0.34 | 0.4 | 0.45 | ||

| Birta kaarboonka sarraysa iyo dhexdhexaad kaarboon bir ah ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Alloy, steel, & steel steel ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Alloy, steel steel (35-48HRC) | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| PH iyo ferritic, biraha martensitic ( | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Gray iron(<32HRC) | 140 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Birta birta ah ee dhibnaanteeda dhexdhexaadinta dhexdhexaadka ah | 130 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 105 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Birta birta dabaysha sare ee aan la jiidi karin, | 120 | 0.1 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.28 | |

| 90 | 0.16 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.29 | ||

| 60 | 0.22 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.35 | ||

| Aluminium aluminium la farsameeyey (Si | 150 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Aluminium daawaha tuura (Si | 150 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 120 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Aluminium daawaha tuura (Si>12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| 12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

Naxaasta,

Fiiro gaar ah:

Hubi in qaybta shaqadu iyo mishiinkuba ay xasiloon yihiin isticmaalna haye sax ah, isticmaal hawo-mareenada, chucks collet tayo sare leh.

Hubi in wadarta dhammaatay ee la tilmaamay (TIR) ay ka yar tahay 0.02mm.

Xaaladda goynta lagu taliyey waxay ku habboon tahay in lagu dabaqo biyaha la milmi karo.

Shirkaddu waxay leedahay line-soo-saarka habka wax soo saarka daab dhamaystiran oo ka soo diyaarinta alaabta ceeriin budada, samaynta caaryada, riixaya, sintering cadaadis, shiidi, daahan iyo daahan daahan ka dib daaweynta. Waxay diiradda saaraysaa cilmi-baarista iyo hal-abuurka ee alaabta saldhigga ah, qaab-dhismeedka jeexdin, samaynta saxda ah iyo daahan dusha sare ee gelinta carbide NC, waxayna si joogto ah u wanaajisaa hufnaanta mashiinnada, nolosha adeegga iyo guryaha kale ee goynta carbide NC. Ka dib in ka badan toban sano oo cilmi-baaris cilmiyeed iyo hal-abuurnimo, shirkaddu waxay kasbatay tiro tignoolajiyada aasaasiga ah ee madax-bannaan, waxay leedahay R&D madax-bannaan iyo awoodaha naqshadeynta, waxayna siin kartaa wax-soo-saar gaar ah macmiil kasta.