- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

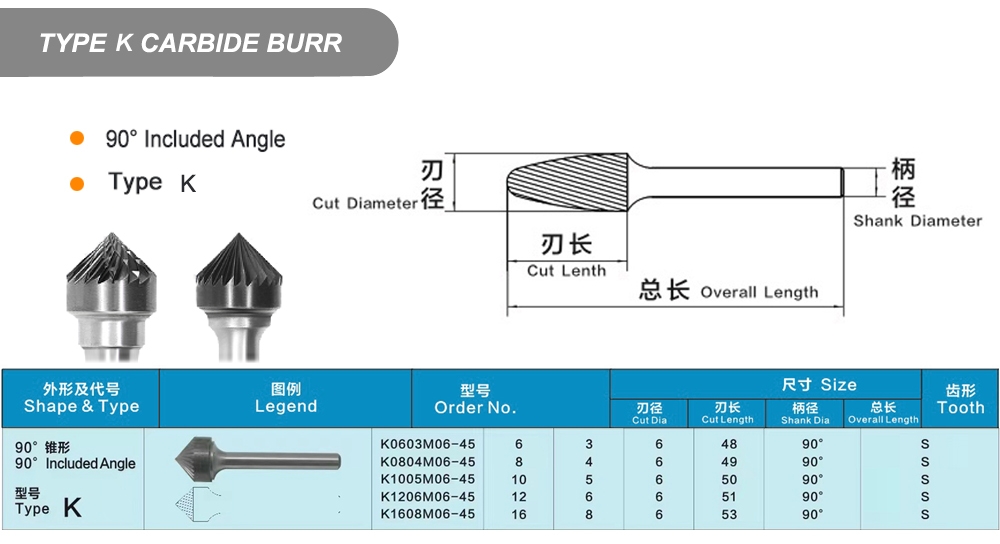

K nooca Carbide Rotary Burr

K nooca faylasha rotary

K nooca Carbide Rotary Burr

hal gooyn & laba-gooyn

Waxyaabaha: Carbiid sibidh ah

alxanka: alxanka qalin

Sharaxaada Alaabta

Carbide daawaha Rotary file waa fitter iyo caaryada shaqada ee lagama maarmaanka ah qalab horumarsan, ay sifo waa beddelka suunka xamili giraangiraha shiidi yar yar iyo wasakhda non-booska, nolosha adeegga waxay la mid tahay dhowr boqol oo suunka xamili giraangiraha shiidi yar yar, waxtarka processing. kor u qaadaya 5 jeer, ka hooseeya darajo machning abrasive ee engegnaanta HRC70 bir kasta iyo mitirka nonmetallic ah, shiidi kara roughness dusha sare laga yaabaa in ay gaaraan Ral.6, ku habboon qabashada, isticmaali si ay u noqoto mid fudud, ammaan ah oo la isku halayn karo, si weyn u yaraynaysaa shaqada buuga adag, yaraynaysaa kharashka wax soo saarka.

Qalabka: 100% alaabta ceeriin.

Dulqaad: xakamaynta xadka dulqaadka adag, kaas oo gaari kara +/- 0.01mm;

Fasalada: kala duwan ee doorashada: YG6, YG8, YG8C, YG11C, YG15C iyo wixii la mid ah.

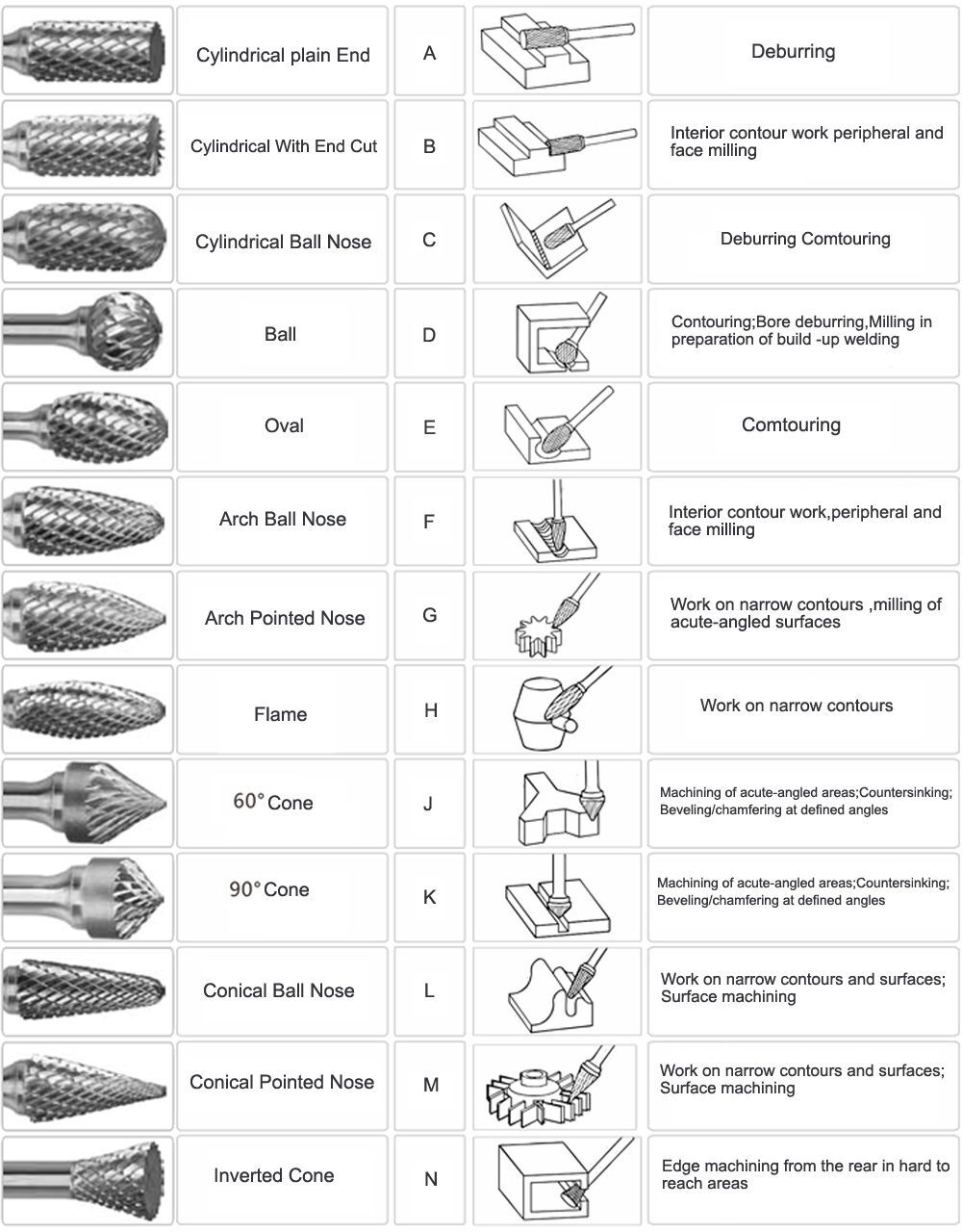

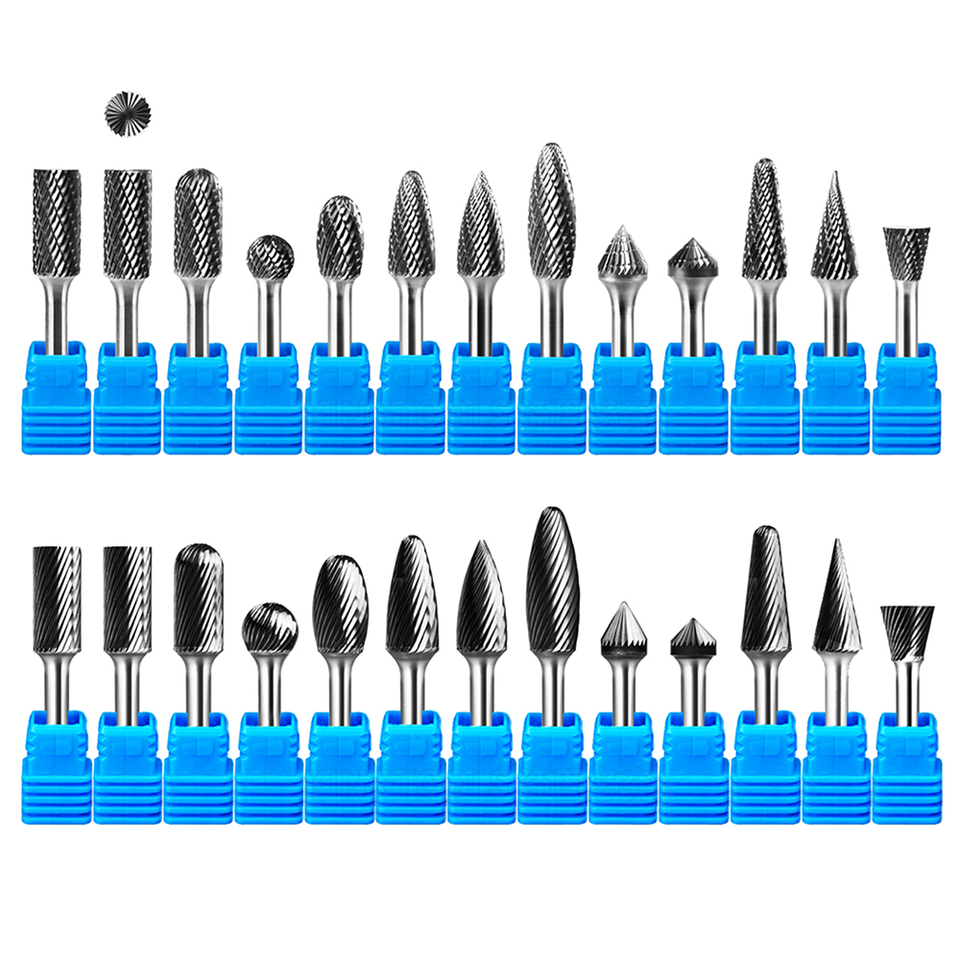

Noocyada: standard, conical, parabolic, ballistic

Waxqabadka jirka: adkaanta sare iyo saamaynta saamaynta, farsamo aad u wanaagsan iyo xasilloonida kiimikada.

nooca/xajmiga alaabta

codsiga alaabta

Faylka rotary carbide cemented waxaa si weyn loogu isticmaalaa mishiinada, baabuurta, markabka, warshadaha kiimikada, xardho farshaxan iyo qaybaha kale ee warshadaha, oo leh saameyn cajiib ah. Isticmaalkeeda ugu weyn waa:

-- Makiin wanaagsan oo godad caaryada birta ah oo kala duwan.

--Nadiifi tooshka, burka iyo alxanka tuurista, alxanka iyo alxanka

--Qalabaynta, soo koobida iyo farsamaynta jeexdin ee qaybo farsamo oo kala duwan, nadiifinta tuubooyinka, iyo dhamaystirka sagxadaha godka gudaha ee qaybaha farsamada

-- Daalidda orodiyaha impeller.

Xakamaynta tayada

1.Dhammaan alaabta ceeriin waxaa lagu tijaabiyaa cufnaanta, adkaanta iyo TRS ka hor inta aan la isticmaalin

2.Wax kasta oo badeecad ah ayaa maraa habka iyo kormeerka ugu dambeeya

3.Qof kasta oo badeecad ah waa la raadin karaa

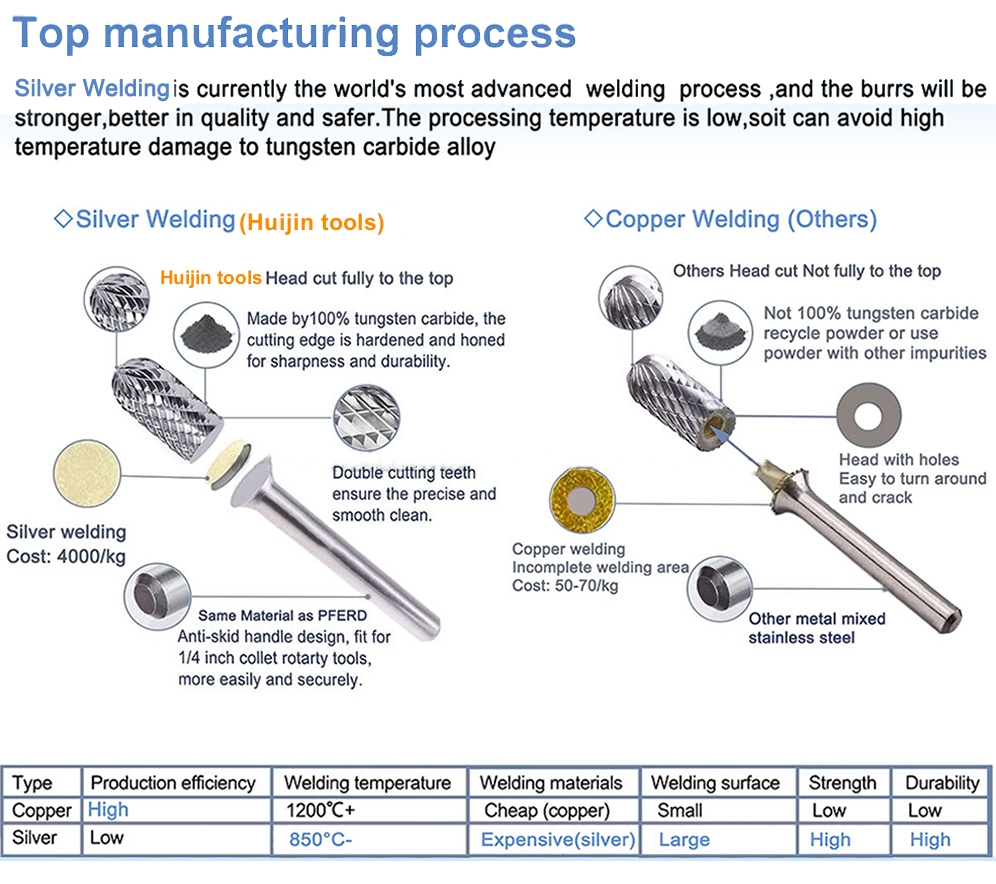

Habka wax-soo-saarka iyo dhamaystirka carbide sibidhka

Birta W\C budada:Budada tungsten nadiif ah oo sarreeya ayaa loo isticmaalaa sida alaab cayriin ah.

Isku darka diyaarinta:Kubbada duubista ayaa ka dhigaysa maaddooyinka budada isku mid ah.Aagga dusha sare ee budada waa la kordhiyey oo dusha sare ee qaybta ayaa kordhay. Kordhin kara oo kor u qaadi kara sintering.

Qalajinta buufinta slurry:Diyaarinta isku dhafka waxaa loo isticmaalaa jawi xiran. Ilaalinta nadaafadda sare ee nitrogen, hoos u dhigista wax ku oolka ah ee diyaarinta. In habka, isku dar ah ayaa laga yaabaa in ay kordhiso ogsijiinta, iyo can.Hubi nadiifinta walxaha iyo ka hortagga walxaha wasakhda ah.

Isku-buufinta:Isticmaalka habka habka cadaadiska taagan, wax ku ool ah du. Caburinta saxda ah ee cilladaha, cufnaanta sare.iyo xitaa.

Degumming iyo ka-hortagga-gubidda ka-hortagga kormeerka-hoosaadka

Vakuum sintering cadaadis hoose:Xakamaynta heerkulbeegga cadaadiska ugu sarreeya wuxuu gaari karaa 100 kg. Nadiifinta godka haraaga ee daahyada ayaa la yareeyaa.Intaa dheer, waa heer sare oo is haysta. Suurtagalnimada isbeddelka tayada ayaa dhacaya.

Qalajinta Semi-dhammeeyay, alaabada madhan carbide

Mashiin sax ah oo xirfad leh

Waxaa jira noocyo badan oo habab-mashiineed oo loogu talagalay mashiinka saxda ah ee carbide. Sida EDM, goynta silig gaabis ah, warshadaynta CNC, farsamaynta lathe CNC, iwm.

CompMid kastaa waa soo-saare xirfad leh oo carbide sibidhka ah oo isku-dhafan wax-soo-saarka iyo mashiinnada saxda ah. Shirkaddu waxay leedahay qalab wax-soo-saar heersare ah oo ay ka mid yihiin leexinta iyo wax-shiidka xarunta mashiinnada isku-dhafka ah, xarun-mashiinnada shan-dhidibka ah, xarunta mashiinnada toosan ee afar-dhidibka ah, Mashiinnada caajiska jiifka ah ee CNC, qodista godka qoto dheer, caajiska iyo honing, foornada vacuum sintering, silig goynta, iwm. Samaynta awoodda taageerada. Waxay leedahay awood aad u xoog badan oo sax ah oo sax ah ee carbide sibidhka, waxaana lagu qalabeeyaa qalabyo kala duwan oo horumarsan, kuwaas oo ku habboon farsamaynta saxsanaanta kala duwan, qalab gaar ah, qaabka gudaha eccentric, suxulada, iyo qaybo joomatari oo adag.

Qalabaynta iyo falanqaynta horumarsan

Huijin waxay ku qalabaysan tahay falanqayn heer sare ah iyo qalab tijaabo ah, sida: falanqeeye carbon sulfur, Tijaabada TRS, mikroskoob metallographic, tijaabiyaha jujuubka, tijaabiyaha magnetic cobalt, tijaabiyaha qallafsanaanta Rockwell, Tijaabada adkaanta Vickers, tijaabiyaha dhibicda, mikrometer, wareega wareega, scanner ultrasonic, iwm ., Nidaam kasta si wax ku ool ah ayaa loola socon karaa si loo hubiyo heerka u qalma ee alaabta.

Kormeerka alaabta ceeriin: isticmaal falanqeeye kaarboon-sulfur si loo go'aamiyo ka kooban kiimikada budada carbide tungsten waa u qalma.

Ka dib markaad isku dhejisid, isticmaal qalabka si aad u tijaabiso walxaha: tijaabi TRS, microstructure, kobalt content, adkaanta walxaha, usha carbide sibidhka iyo tijaabada dhibicda si loo hubiyo in aysan jirin cillad dhexdhexaad ah oo gudaha ah oo gudaha ah, caaryada carbide cemented maran, ku dar ultrasonic scanner si looga fogaado cammuudda godka banaan.

Kormeerka alaabta gacanta ka dib sintering: Kormeerka muuqaalka ah ee cilladaha alaabta ee shaqaale xirfad leh, oo ay ku jiraan carburization iyo carburization, godadka ciidda dusha sare, dildilaaca yaryar.

Jeegaynta cabbirka ka dib markaad isku dhejiso: Ku eeg cabbirada mikrometer, iyo ulaha carbide, ku dar baaritaanka wareega.

Hababka gaarsiinta/Baakaynta

-Shirkadaha Express: DHL, FedEx, TNT, UPS, iwm.

-Shirkadaha diyaaradaha.

-Dhxinta badda

A. Xirmooyinka caadiga ah

Sanduuqyada caaga ah ee gudaha xumbo ku leh iyo kartoon dibadda ah.

-Sanado waraaqo ah oo gudaha xumbo ku leh iyo kartoon dibadda ah.

Sanduuqyada gudaha/waxyaabaha baakadeynta gudaha iyo sanduuqa alwaaxa dibadda ah ( alaabta culus)

Shirkaddu waxay leedahay line-soo-saarka habka wax soo saarka daab dhamaystiran oo ka soo diyaarinta alaabta ceeriin budada, samaynta caaryada, riixaya, sintering cadaadis, shiidi, daahan iyo daahan daahan ka dib daaweynta. Waxay diiradda saaraysaa cilmi-baarista iyo hal-abuurka ee alaabta saldhigga ah, qaab-dhismeedka jeexdin, samaynta saxda ah iyo daahan dusha sare ee gelinta carbide NC, waxayna si joogto ah u wanaajisaa hufnaanta mashiinnada, nolosha adeegga iyo guryaha kale ee goynta carbide NC. Ka dib in ka badan toban sano oo cilmi-baaris cilmiyeed iyo hal-abuurnimo, shirkaddu waxay kasbatay tiro tignoolajiyada aasaasiga ah ee madax-bannaan, waxay leedahay R&D madax-bannaan iyo awoodaha naqshadeynta, waxayna siin kartaa wax-soo-saar gaar ah macmiil kasta.