- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

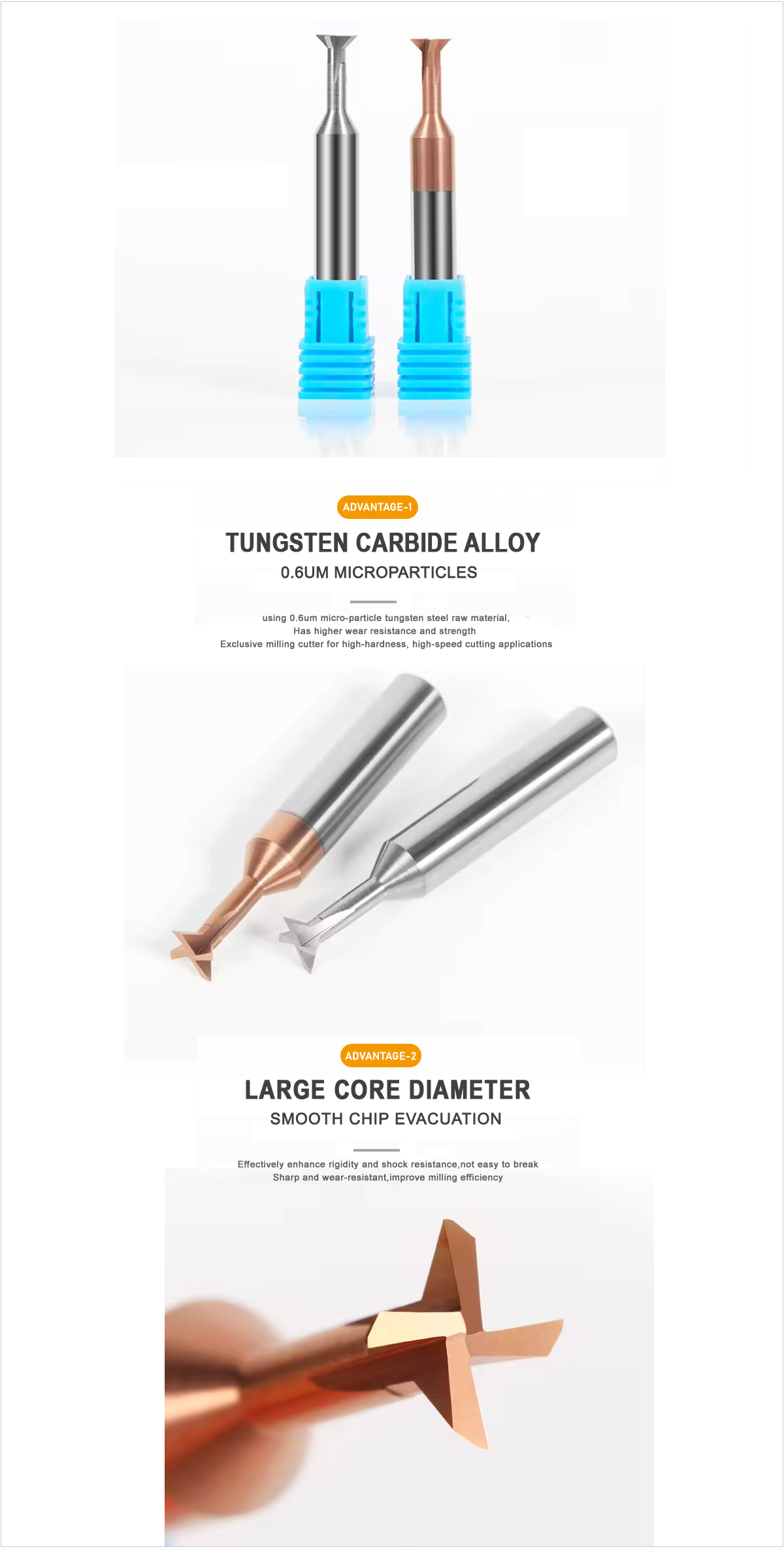

Yakagadzirirwa CNC Isiri-yakajairwa Solid Carbide Dovetail Kugadzira Endmill T-slot Milling Cutter

CNC Zvishandiso Steel Aluminium Dovetail Groove Cutter T Slot

4-kumucheto dovetail milling cutter

Customized Non-standard Dovetail End Milling Cutter

Nyanzvi muKugadzira Kwetsika Isiri-yakajairwa T-mhando Dovetail Cnc Tungsten Steel

| Zita | Dovetail Groove Trough T Slot T-Slot T-Milling Cutter |

| Material | Cemented carbide |

| Coating | AITIN/customized |

| Angle | 30°/45°/60°/90° |

| Hurefu hwese | 50-60mm kana customized |

| Inokodzera | Simbi isina simbi, Carbon Steel, Mold steel, Cast Iron,aluminium |

| Application | Side milling slotting, T-shaped slotting, deep slotting, kugaya ndege |

| Zvose zvinotsanangurwa. inogona kugadzirwa | |

Zvatinakira:

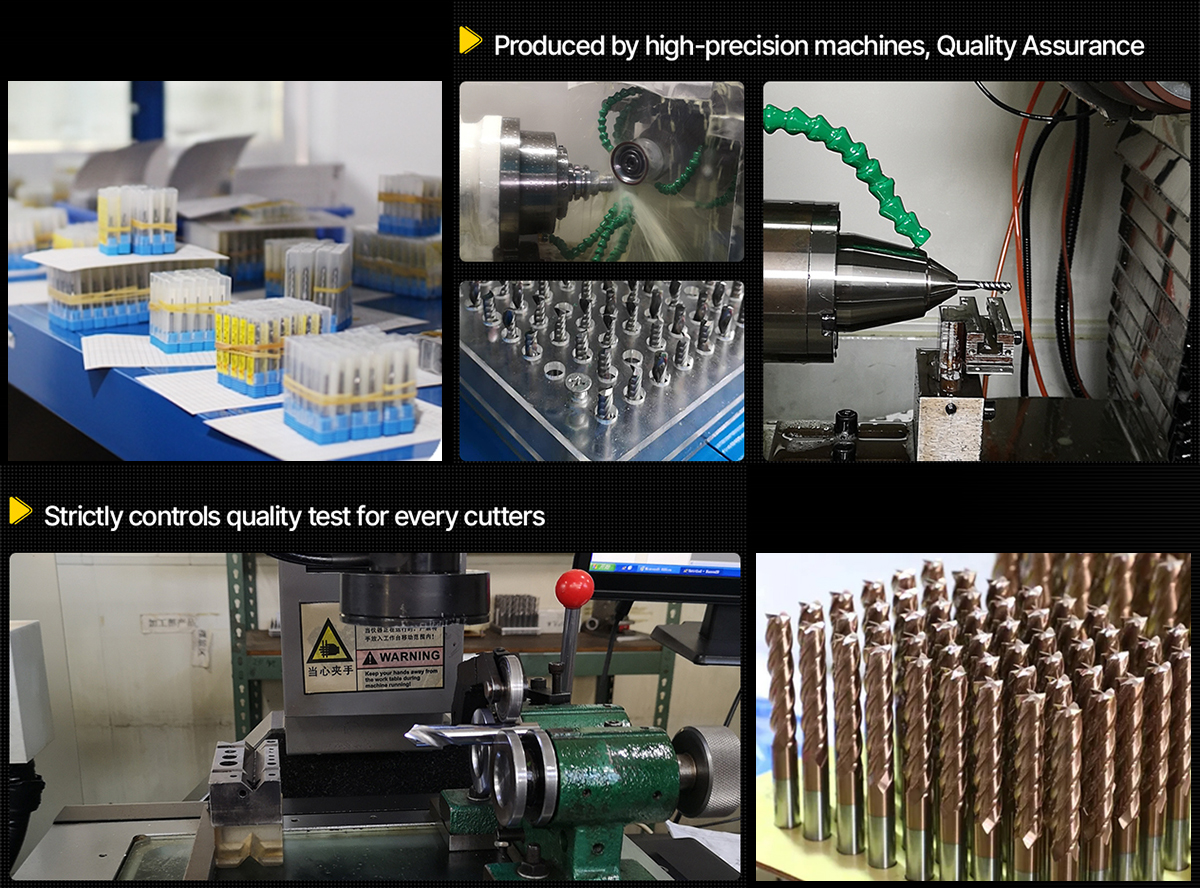

Chikwata chehunyanzvi chekugadzira: Iva neanopfuura makore gumi ruzivo rwekugadzira pane carbide yakaiswa.

Kurumidza kuburitsa kunoenderana nepamusoro kugadzirwa kugona.

Strict quality control system: Ita shuwa chigadzirwa chedu mune yakanaka uye yakagadzikana mhando.

Zvakapfuma ruzivo pane zvakagadziridzwa zvigadzirwa.

Tsigiro yehunyanzvi: Batsira iwe kuwana mhinduro yakanaka.

T-slot Dovetail End Mills

Aya akakosha ekucheka anogadzirwa neazvino-e-art michina uye matekiniki, anogonesa vatengi vedu kuve yakanaka T slotting ruzivo. Inoda chigadziro chakaomarara kubata uye kumhanya nemazvo kudzivirira kutyoka. Chigadzirwa chine coating ndeyekugadzirisa simbi uye isina chinhu yealuminium.

Professional Carbide End mill Manufacture

Saizi (yakajairwa uye isiri-yakajairwa)

Standard:

yedu yakajairwa carbide milling cutters inovhara dhayamita kubva pa2mm kusvika 12mm kusangana nepasirese kugadzirwa manejimendi uye mhando zviyero.

Zvisiri-Standard:

Fekitori yedu inogona kugadzira izvo zvisiri-yakajairwa zvigadzirwa zvinoenderana nehunyanzvi hwekudhirowa kana masampuli.

Saizi yenguva dzose:

| Tsanangudzo | ||||||

| Mill Diameter D1/(mm) | Angle | Mill Height H/(mm) | Kunzvenga Diameter d/(mm) | Hurefu hwehuro h/(mm) | Shank Diameter D2/(mm) | Overall Length L/(mm) |

| 2 | 60 | 0.32 | 0.9 | 4 | 4 | 50 |

| 3 | 60 | 0.47 | 1.4 | 6 | 4 | 50 |

| 4 | 60 | 0.62 | 1.9 | 8 | 4 | 50 |

| 5 | 60 | 0.79 | 2.3 | 10 | 6 | 50 |

| 6 | 60 | 0.94 | 2.8 | 10 | 6 | 50 |

| 8 | 60 | 1.29 | 3.6 | 12 | 8 | 60 |

| 10 | 60 | 1.61 | 4.5 | 15 | 10 | 60 |

| 12 | 60 | 1.94 | 5.4 | 18 | 12 | 60 |

| 2 | 45 | 0.55 | 0.9 | 4 | 4 | 50 |

| 3 | 45 | 0.8 | 1.4 | 6 | 4 | 50 |

| 4 | 45 | 1.05 | 1.9 | 8 | 4 | 50 |

| 5 | 45 | 1.35 | 2.3 | 10 | 6 | 50 |

| 6 | 45 | 1.6 | 2.8 | 10 | 6 | 50 |

| 8 | 45 | 2.2 | 3.6 | 12 | 8 | 60 |

| 10 | 45 | 2.75 | 4.5 | 15 | 10 | 60 |

| 12 | 45 | 3.3 | 5.4 | 18 | 12 | 60 |

| 2 | 30 | 0.96 | 0.9 | 4 | 4 | 50 |

| 3 | 30 | 1.4 | 1.4 | 6 | 4 | 50 |

| 4 | 30 | 1.84 | 1.9 | 8 | 4 | 50 |

| 5 | 30 | 2.37 | 2.3 | 10 | 6 | 50 |

| 6 | 30 | 2.81 | 2.8 | 10 | 6 | 50 |

| 8 | 30 | 3.86 | 3.6 | 12 | 8 | 60 |

| 10 | 30 | 4.82 | 4.5 | 15 | 10 | 60 |

| 12 | 30 | 5.79 | 5.4 | 18 | 12 | 60 |

Iyo kambani ine yakazara blade yekugadzira michina yekugadzira michina mutsara kubva paupfu kugadzirwa kwezvinhu, kugadzira mold, kudzvanya, kudzvanya sinter, kugaya, kupeta uye kupeta mushure mekurapa. Inotarisa pakutsvagisa uye kuvandudzwa kwezvinhu zvepasi, groove chimiro, kunyatso kuumbwa uye kuvharika kwepamusoro kwecarbide NC inoisa, uye inogara ichivandudza machining kunyatsoita, hupenyu hwebasa uye zvimwe zvekucheka zvivakwa zvecarbide NC inoisa. Mushure memakore anopfuura gumi ekutsvagisa kwesainzi uye hunyanzvi, kambani yakabata akati wandei yakazvimirira tekinoroji, ine yakazvimiririra R&D uye dhizaini kugona, uye inogona kupa yakagadziridzwa kugadzirwa kune wega mutengi.