- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

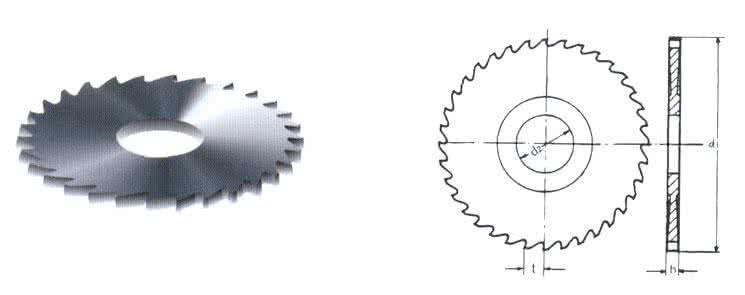

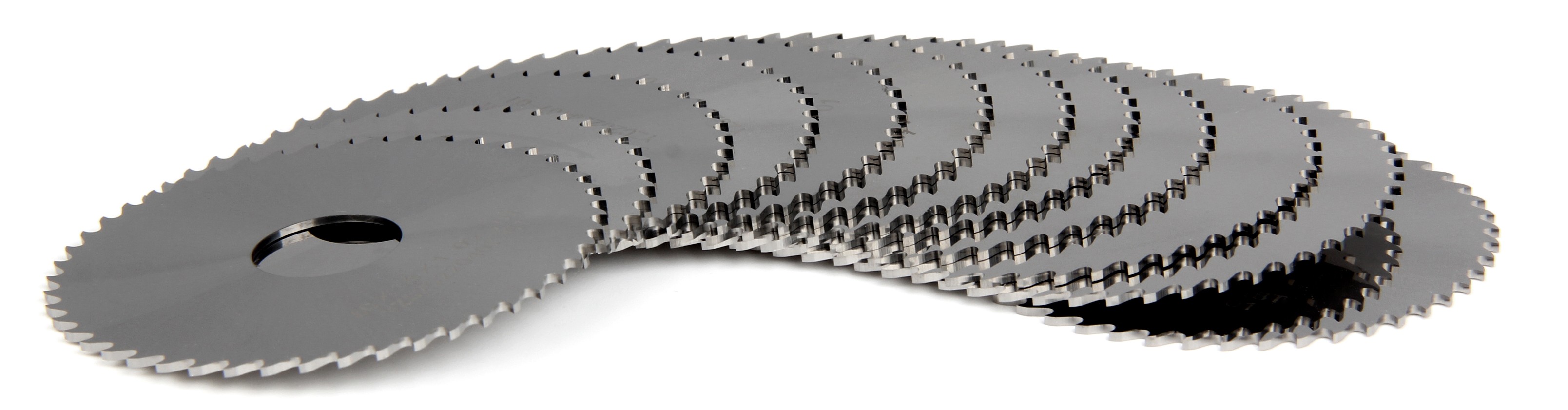

Tungsten carbide round cutting saw blades

Carbide saw blade cutter

Saizi : 75*25.4*T1.0-72T

Inokodzera Metal uye huni Machining

Kuoma: 92.6 HRA

Mazino : 72T

Tungsten carbide round cutting saw blades

Mazhinji ekucheka masaha akagadzirwa nemhando imwechete yesimbi yekumhanya, carbide uye zvimwe zvinhu. Kana ichienzaniswa nesimbi yekumhanyisa, iyo carbide ine kuoma kwepamusoro, simba rekucheka rakasimba, kumhanya kwepamusoro uye chiyero chekudya, uye kugadzirwa kwakanyanya.

Inoshandiswa zvakanyanya mu: magirazi, wachi, muchina, zvemagetsi, mota uye mamwe maindasitiri

Zvakanakira zve Tungsten carbide round cutting saw blades, carbide saw cutters

1. Iine submicron saizi yezviyo, Yakanaka kupfeka-inodzivirira, hupenyu hwesevhisi hurefu.

2. With yakasimba kushivirira pamwero kudzora

3. Nakidzwa zvakanaka kupfeka kuramba & yakakwirira toughnes

4. Yakakosha yeHot Isostatic Press (HIP) maitiro inopa kuvandudzwa kwemhando kune zvakapedzwa zvigadzirwa kuti ive nechokwadi chekuvimbika kwemeta.

5. Isu tinonyatso sarudza giredhi rinodiwa kuti rive rakanyanya kucheka kuita kunoenderana nemakore echiitiko mumunda

| External dhayamita(D) | Hukobvu(H) | Inner diameter(d) | Teet(T) |

| 25 | 0.2--5.0 | 6 8 10 | 10--58 |

| 30 | 0.2--5.0 | 6 8 10 | 10--60 |

| 32 | 0.2--6.0 | 6 8 10 12.7 | 10--60 |

| 35 | 0.2--6.0 | 8 10 12.7 | 10--60 |

| 40 | 0.2--6.0 | 8 10 12.7 | 10--80 |

| 45 | 0.2--8.0 | 10 12.7 16 | 10--80 |

| 50 | 0.2--8.0 | 10 12.7 16 | 10--100 |

| 55 | 0.2--8.0 | 12.7 16 | 24--120 |

| 60 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 63 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 70 | 0.3--8.0 | 16 22 25.4 | 28--120 |

| 75 | 0.5--8.0 | 16 22 25 4 | 30--120 |

| 80 | 0.5--8.0 | 22 25.4 | 30--128 |

| 85 | 0.5--8.0 | 22 25.4 | 30--128 |

| 90 | 0.5--8.0 | 22 25.4 | 30--160 |

| 100 | 0.5--8.0 | 22 25.4 27 | 30--160 |

| 110 | 0.8--8.0 | 22 25.4 27 32 | 30--180 |

| 120 | 1.0--10.0 | 22 25.4 27 32 | 30-240 |

| 125 | 1.0--10.0 | 22 25.4 27 | 30-240 |

| 150 | 1.0--10.0 | 22 25.4 27 32 | 40-240 |

Tool material kuumbwa:

C) TRS yakakura kupfuura kana yakaenzana ne3800 N/mm²;

Iyo kambani ine yakazara blade yekugadzira michina yekugadzira michina mutsara kubva paupfu kugadzirwa kwezvinhu, kugadzira mold, kudzvanya, kudzvanya sinter, kugaya, kupeta uye kupeta mushure mekurapa. Inotarisa pakutsvagisa uye kuvandudzwa kwezvinhu zvepasi, groove chimiro, kunyatso kuumbwa uye kuvharika kwepamusoro kwecarbide NC inoisa, uye inogara ichivandudza machining kunyatsoita, hupenyu hwebasa uye zvimwe zvekucheka zvivakwa zvecarbide NC inoisa. Mushure memakore anopfuura gumi ekutsvagisa kwesainzi uye hunyanzvi, kambani yakabata akati wandei yakazvimirira tekinoroji, ine yakazvimiririra R&D uye dhizaini kugona, uye inogona kupa yakagadziridzwa kugadzirwa kune wega mutengi.