- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

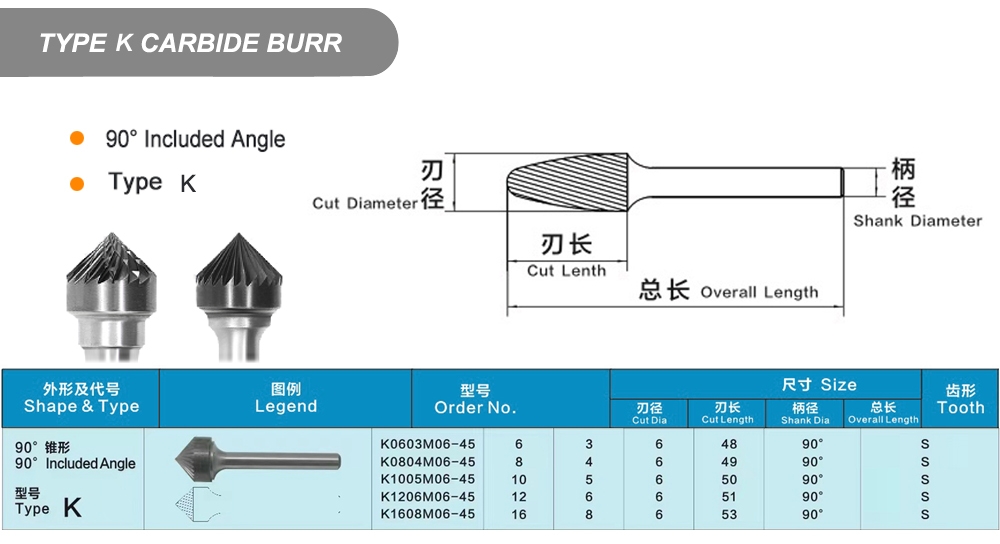

K mhando Carbide Rotary Burr

K mhando mafaera anotenderera

K mhando Carbide Rotary Burr

single cut & double-cut

zvinhu: Cemented carbide

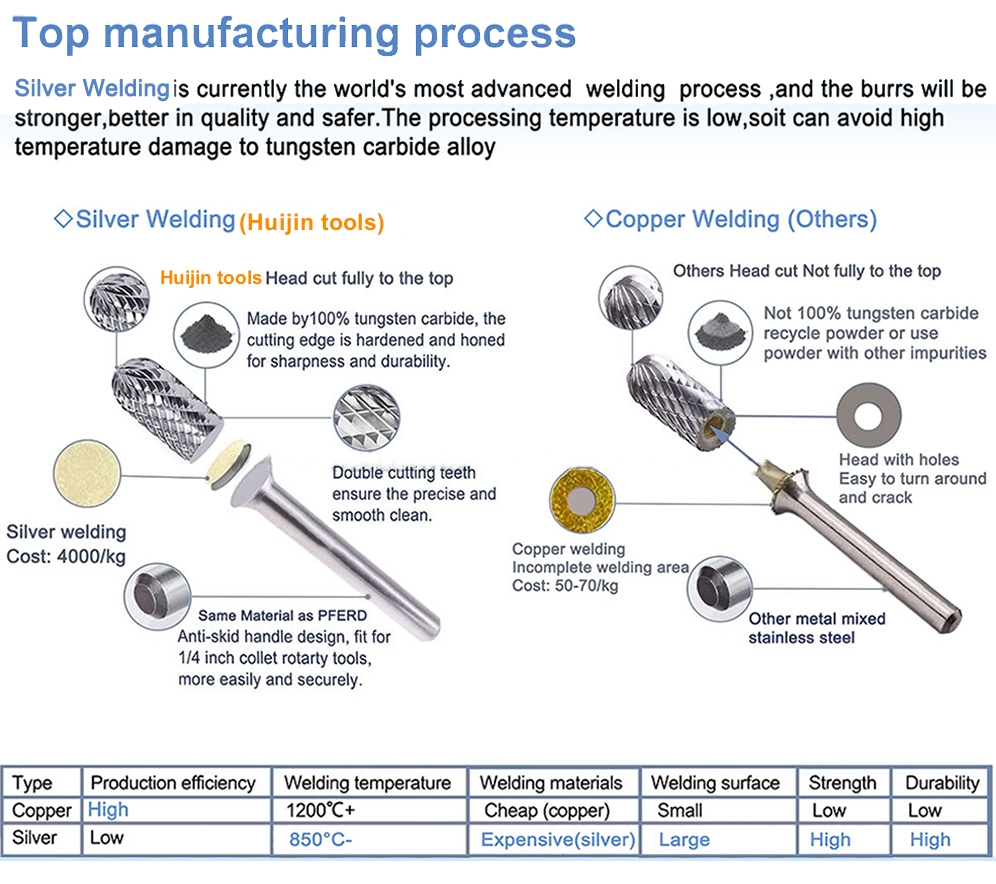

welding: sirivha welding

Product Description

Iyo carbide alloy rotary faira ndiyo inokwana uye mold yebasa yakakosha chishandiso chepamusoro, hunhu hwayo hunotsiva bhandi rinobata diki rekukuya vhiri uye kusvibiswa kusiri kweguruva, hupenyu hwesevhisi hwakaenzana nemazana akati wandei ebhandi kubata vhiri diki rekukuya, kugadzirisa kushanda zvakanaka. inowedzera pamusoro pe5 nguva, pazasi abrasive machning dhigirii yekuomarara HRC70 simbi imwe neimwe uye iyo isiri metallic meterial, kukuya pamusoro roughness inogona kusvika kuRal.6, nyore kubata, kushandisa kuve nyore, yakachengeteka yakavimbika, inoderedza basa rakaoma remanyorero zvakanyanya, kuderedza mutengo we production.

Material: 100% yezvinhu zvakasvibiswa.

Kushivirira: kwakasimba kushivirira chiyero chekudzora, chinogona kusvika +/-0.01mm;

Magiredhi: akasiyana ekusarudza: YG6, YG8, YG8C, YG11C, YG15C zvichingodaro.

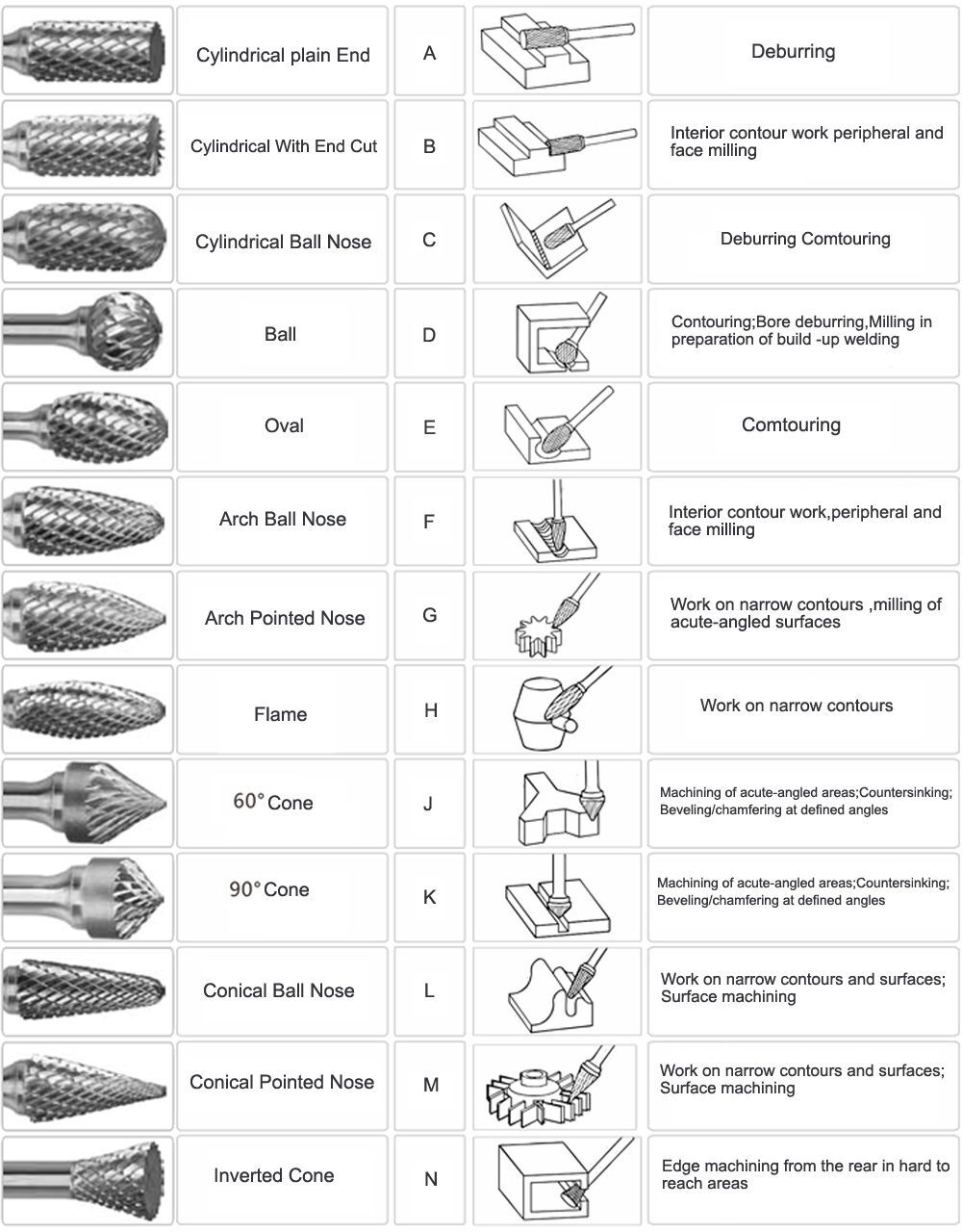

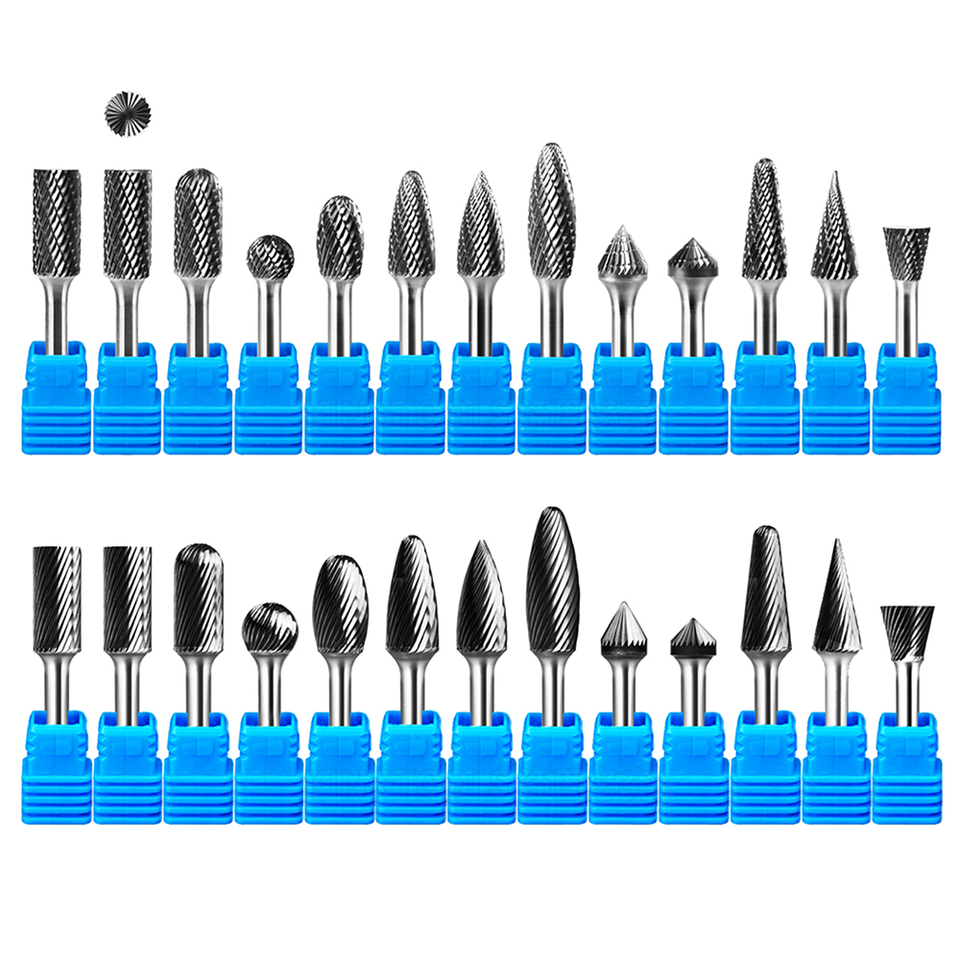

Mhando: mureza, conical, parabolic, ballistic

Kuita kwemuviri: kuomarara kwakanyanya uye kukanganisa kuoma, yakanaka kwazvo mechaniki & kugadzikana kwemakemikari.

chigadzirwa rudzi/saizi

chigadzirwa application

Cemented carbide rotary faira inoshandiswa zvakanyanya mumakina, mota, ngarava, indasitiri yemakemikari, kuveza kuveza uye mamwe maindasitiri zvikamu, zvine mhedzisiro inoshamisa. Mashandisiro ayo makuru ndeaya:

-- Fine machining akasiyana simbi mold cavities.-- Mhando dzese dzesimbi, dzisiri dzesimbi kuveza, uye kuveza zvipo zvehunyanzvi.

--Chenesa mwenje, burr uye weld yekukanda, forging uye weldments

--Chamfering, kutenderera uye groove kugadziridzwa kweakasiyana mekiniki zvikamu, kucheneswa kwepombi, uye kupedzisa kwemukati megomba nzvimbo dzemechanicha zvikamu.

-- Kupenya kwe impeller mumhanyi.

Quality control:

1.Zvose zvakasvibiswa zvinoedzwa maererano nehuwandu, kuoma uye TRS isati yashandiswa

2.Chidimbu chega chega chechigadzirwa chinopinda mu-process uye kuongorora kwekupedzisira

3.Every batch yechigadzirwa inogona kuteverwa

Maitiro ekugadzira uye kupedzisa simende carbide

Metal W\C Upfu:Yakakwira kuchena tungsten poda inoshandiswa seyakabikwa.

Musanganiswa wekugadzirira:The rolling ball mill makes the powder ingredients homogenize.The surface area of the powder is added and the particle surface is added.Inogona kuwedzera uye kukurudzira sintering.

Slurry spray drying:Kugadzirira kwekusanganiswa kunoshandiswa munzvimbo yakavharwa.Kuchena kwakachena nitrogen kudzivirira, kuderera kunobudirira kwekugadzirira.Mukuita, musanganiswa unogona kuwedzera oksijeni, uye unogona.Iva nechokwadi chekuchena kwezvinhu uye kudzivirira zvinhu.Iyo yakasvibiswa.

Compression Moulding:Kushandisa nzira ye static pressure mechanism, inoshanda du.Absolute kudzvinyirirwa kwekuremara, high density.uye kunyange.

Degumming uye pre-kupisa semi-kuongorora kugadzirisa

Vacuum low pressure sintering:thermostatic sintering Maximum sintering pressure inogona kusvika 100 kg. The residual gole clearance mu alloy inoderedzwa.Mukuwedzera, yakanyanya compactand good.Degree, high simba alloy blank.Advanced control,The tembiricha system inogona kunyatso dzikisa hard alloy plate. Iko kugona kwekushanduka kwemhando kunoitika.

Semi-yakapedza kuomesa, carbide isina zvigadzirwa

Professional precision machining

Kune akawanda marudzi emachining nzira dze carbide precision machining. Zvakadai seEDM, kunonoka kucheka waya, CNC milling, CNC lathe processing, nezvimwe.

Complete yeduchero inyanzvi inogadzira simende carbide inobatanidza kugadzirwa uye chaiyo machining. Kambani ine advanced kugadzira uye kugadzira michina senge kutenderedza uye kugaya kombi machining Center, shanu-axis machining Center, ina-axis vertical machining centre, CNC yakatwasuka inofinha uye muchina wekugaya, kuchera gomba rakadzika, kufinha nekukudza, vacuum sintering vira, waya. kucheka, etc. Processing inotsigira simba. Iine simba rakasimba mukugadzirwa kwecemented carbide, uye yakashongedzerwa nemichina yakasiyana-siyana yekugadzira, inokodzera kugadzirwa kwemhando dzakasiyana-siyana dzepamusoro-soro, zvinhu zvakakosha, chimiro chemukati chemukati, magokora, uye zvikamu zvakaoma zvejometri.

Kuongorora kwepamusoro uye midziyo yekuongorora

Huijin inoshongedzerwa nekuongorora kwepamusoro uye midziyo yekuyedza, yakadai se: kabhoni sulfur analyzer, TRS tester, metallographic microscope, coercivity tester, cobalt magnetic tester, Rockwell hardness tester, Vickers hardness tester, drop tester, micrometer, roundness tester, ultrasonic scanner, nezvimwe. ., maitiro ega ega anogona kunyatsotariswa kuti ive nechokwadi chemhando yezvigadzirwa.

Raw material yekuongorora: shandisa kabhoni-sarufa analyzer kuona kemikari ye tungsten carbide poda inokodzera.

Mushure mekunyura, shandisa chiridzwa kuyedza izvo zvinhu: edza iyo TRS, microstructure, cobalt zvemukati, kuoma kwezvinhu, simende carbide tsvimbo uye donhwe bvunzo kuona kuti hapana chepakati chakakanganisika mukati mechinhu, simende carbide mold isina chinhu, wedzera ultrasonic. scanner yekudzivirira jecha Hole mukati isina chinhu.

Manual material yekuongorora mushure mekuita sintering: Kuongororwa kwekuona kwekuremara kwezvinhu nevashandi vane hunyanzvi, kusanganisira carburization uye decarburization, maburi ejecha repamusoro, madiki madiki.

Dimensional cheki mushure mekunyura: Tarisa zviyero ne micrometer, uye ye carbide tsvimbo, wedzera kutenderera bvunzo.

Nzira dzekutumira / Kurongedza

-Express makambani: DHL, FedEx, TNT, UPS, nezvimwe.

-Ndege.

-Ocean shipping

A. Standard kurongedza

-Mabhokisi epurasitiki ane furo mukati uye katoni kunze.

-Mapepa mabhokisi ane furo mukati uye katoni kunze.

-Mabhokisi emukati / kurongedza zvinhu mukati uye plywood bhokisi kunze (yechigadzirwa chinorema)

Iyo kambani ine yakazara blade yekugadzira michina yekugadzira michina mutsara kubva paupfu kugadzirwa kwezvinhu, kugadzira mold, kudzvanya, kudzvanya sinter, kugaya, kupeta uye kupeta mushure mekurapa. Inotarisa pakutsvagisa uye kuvandudzwa kwezvinhu zvepasi, groove chimiro, kunyatso kuumbwa uye kuvharika kwepamusoro kwecarbide NC inoisa, uye inogara ichivandudza machining kunyatsoita, hupenyu hwebasa uye zvimwe zvekucheka zvivakwa zvecarbide NC inoisa. Mushure memakore anopfuura gumi ekutsvagisa kwesainzi uye hunyanzvi, kambani yakabata akati wandei yakazvimirira tekinoroji, ine yakazvimiririra R&D uye dhizaini kugona, uye inogona kupa yakagadziridzwa kugadzirwa kune wega mutengi.