- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

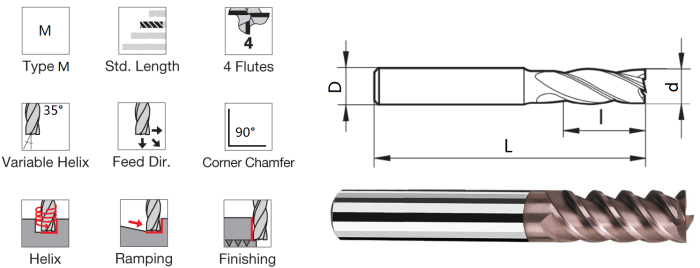

F4 End mill ye general machining yesimbi isina tsvina

HJS600 yakatevedzana - General Machining yeStainless Simbi

HJS600 yakatevedzana - General Machining yeStainless Simbi

Inokodzera general machining eStainless simbi (

Universal Yepamusoro Performance Coating AlCrSiN

F4

Chirevo chechokwadi:

Simbi isina simbi ine Si, Ni uye imwe simbi inomira, saka kuoma kwayo uye kusimba kwakanaka kwazvo. Patinenge tichigadzira stainless steel endmills, tinoshandisa micro tungsten carbide, uye special coating , kuitira kuti zvinhu zvifambe zvakanaka. Iyi nhevedzano yemaendmill anga achigadzira kubva kuIphone 5 ye304 stainless simbi chimiro, uye akawana mibairo yakanaka, uye akahwina kurumbidzwa kukuru kubva kuFOXCNN neMiYa.

Features:

Inokodzera general machining yesimbi isina tsvina (

Special edge design, zvinobudirira kugadzirisa zvimedu.

Kutonhora kwemvura, kutonhora kwemafuta ndiyo nzira dzakanakisa dzekutonhora.

Saizi yenguva dzose:

| Kuodha kodhi | Kunze Diameter | Flute Kureba | Kureba | Shank Diameter |

| (d) | (l) | (L) | (D) | |

| HJS600-4F-D010-L050 | 1.0 | 3.0 | 50 | 4 |

| HJS600-4F-D015-L050 | 1.5 | 4.5 | 50 | 4 |

| HJS600-4F-D020-L050 | 2.0 | 6.0 | 50 | 4 |

| HJS600-4F-D025-L050 | 2.5 | 7.0 | 50 | 4 |

| HJS600-4F-D030-L050 | 3.0 | 8.0 | 50 | 4 |

| HJS600-4F-D035-L050 | 3.5 | 10.0 | 50 | 4 |

| HJS600-4F-D040-L050 | 4.0 | 11.0 | 50 | 4 |

| HJS600-4F-D050-L050 | 5.0 | 13.0 | 50 | 6 |

| HJS600-4F-D060-L050 | 6.0 | 16.0 | 50 | 6 |

| HJS600-4F-D070-L060 | 7.0 | 17.0 | 60 | 8 |

| HJS600-4F-D080-L060 | 8.0 | 20.0 | 60 | 8 |

| HJS600-4F-D090-L075 | 9.0 | 25.0 | 75 | 10 |

| HJS600-4F-D100-L075 | 10.0 | 25.0 | 75 | 10 |

| HJS600-4F-D110-L075 | 11.0 | 28.0 | 75 | 12 |

| HJS600-4F-D120-L075 | 12.0 | 30.0 | 75 | 12 |

| HJS600-4F-D140-L080 | 14.0 | 35.0 | 80 | 14 |

| HJS600-4F-D160-L100 | 16.0 | 45.0 | 100 | 16 |

| HJS600-4F-D180-L100 | 18.0 | 48.0 | 100 | 18 |

| HJS600-4F-D200-L100 | 20.0 | 50.0 | 100 | 20 |

Tool material kuumbwa:

1. Zvinhu Zvenyama:

a. Kuoma kukuru kupfuura kana kuenzana ne92.8 HRA;

b. Density yakakura kudarika kana yakaenzana ne14.2g/cm³;

c. TRS yakakura kupfuura kana yakaenzana ne4200 N/mm²;

d. Yemahara ye ETA chikamu mamiriro;

e. Hapana kusvibiswa nezvimwe zvinhu;

f. Porosity = A00/ B00 / C00 ;

g. Uniform uye kuenderana saizi yezviyo. Hapana saizi yezviyo inogona kuve yakakura kupfuura yakatsanangurwa.

h. Chromium carbide zviyo kukura inhibitor chete.

2. Zvishandiso zvese zvekugadzira, machira anoshandiswa kuGermany, Switzerland, midziyo yekugadzirisa;

Coating:

Universal Yepamusoro Performance Coating AlCrSiN

Hunhu uye Basa

1、Kugadzirwa kunowedzera nekuda kwekumhanya kwakanyanya kwekucheka uye chikafu chekushandisa mumhando dzakasiyana dzezvinhu.

2, Kunyanya dhizaini yechimiro inounza chiyero chakanaka pakati pekuoma, thermo-shock kugadzikana uye kusara kunetseka.

Coating:

1, Universal High Performance Coating AlCrSiN:

2, Kunyanya dhizaini yechimiro inounza chiyero chakanaka pakati pekuoma, thermo-shock kugadzikana uye kusara kunetseka.

Operation parameter:

| HJS600 S4 For Stainless Steels-Side Milling | ||||||||||||||

| MaGrades | Chimiro chishandiso | Workpiece | Kucheka Kudzika | VC m/min | Tool Diameter | 1 | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| S4 | Material | (mm) | (mm) | |||||||||||

| DLTUS600 | Square, | Simbi isina ngura | ap≤1D | 100 | Speed | 25000 | 15900 | 7960 | 5300 | 3980 | 3180 | 2650 | 1990 | 1590 |

| Corner radius | (80-120) | (min-1) | ||||||||||||

| ae≤0.1D | Feed Speed | 700 | 635 | 700 | 680 | 730 | 660 | 600 | 490 | 460 | ||||

| (mm/min) | ||||||||||||||

Chenjerera:

Ita shuwa kuti chidimbu chebasa uye muchina zvakagadzikana uye shandisa chaiyo inobata.

Ndokumbira ugadzirise kumhanya, kudya uye kudzika kudzika zvinoenderana nemamiriro chaiwo ekucheka.

Mamilling conditiongs ndeechigayo chekupedzisira apo kureba kwemudziyo kunodarika 4*D(mill dia). Kana chishandiso chakawedzera kureba, ndapota gadzirisa kumhanya, kudya uye kucheka kudzika.

Iyo kambani ine yakazara blade yekugadzira michina yekugadzira michina mutsara kubva paupfu kugadzirwa kwezvinhu, kugadzira mold, kudzvanya, kudzvanya sinter, kugaya, kupeta uye kupeta mushure mekurapa. Inotarisa pakutsvagisa uye kuvandudzwa kwezvinhu zvepasi, groove chimiro, kunyatso kuumbwa uye kuvharika kwepamusoro kwecarbide NC inoisa, uye inogara ichivandudza machining kunyatsoita, hupenyu hwebasa uye zvimwe zvekucheka zvivakwa zvecarbide NC inoisa. Mushure memakore anopfuura gumi ekutsvagisa kwesainzi uye hunyanzvi, kambani yakabata akati wandei yakazvimirira tekinoroji, ine yakazvimiririra R&D uye dhizaini kugona, uye inogona kupa yakagadziridzwa kugadzirwa kune wega mutengi.