Tungsten carbide, inozivikanwawo secemented carbide, chinhu chakakosha zvinhu izvo zvakakosha kune akawanda maitiro ekugadzira. Mazhinji simbi machining maitiro anoshandisa tungsten carbide inoisa sematipi ezvishandiso, sezvo simende carbide ine yakanakisa kuomarara uye kupisa kupisa zvivakwa zvakanakira kudhiraivha, kufinha, kuumba uye kugadzira simbi yekushanda. Mazhinji emazuva ano anotarisana nezvigayo, lathe maturusi uye ekupedzisira zvigayo anoshandisa aya maturusi ekucheka.

Ko Tungsten Carbide Insets inogadzirwa sei?

Kugadzira uye kugadzira zvitoro zvinotsamira pane tungsten carbide inoisa yekumhanyisa maturusi zvinowanzopfuura nezviuru zvekuisa gore rega rega. Vashandisi vemichina vanoshanda nevakawanda vanoisa zuva rega rega, vachivimba nekusanganiswa kwavo kwakaoma kwekemistry uye geometry kuti vape mipendero yekucheka inodiwa pakurongeka, kukurumidza kugadzirwa. Kunzwisisa kuti kuiswa kwecarbide kunogadzirwa sei uye kuti maitiro ekugadzira ekuisa anopesvedzera kugona kwavo kunogona kubatsira vashandisi vemichina nevagadziri kuti vanzwisise zviri nani maturusi avo uye maitiro ese.

Tungsten carbide inoisa ine simende carbide, iyo inogadzirwa kubva musanganiswa wecobalt uye tungsten carbide. Tungsten carbide's hard particles mukati meiyo inopinza inopa iyo yekuisa nehunhu hwayo hwekuoma, uye cobalt inoshanda sechinhu chinosunga, ichibata zvinhu zvacho zvakasimba pamwechete. Saizi yezviyo tungsten iri kushandiswa inokanganisa kuomarara kwekuisa; zviyo zvakakura (3-5 microns) zvinokonzeresa zvinyoro, zvinokurumidza kupfekwa zvekuisa zvinhu, nepo zviyo zvidiki (zvisingasviki 1 micron) zvichikonzera kuoma zvakanyanya, kupfeka zvinoiswa zvinodzivirira. Iyo yakanyanya kuoma kuisa, iyo inowedzera brittle iyo ichava. Kana uchigadzira simbi dzekuomarara kwakasarudzika, kuiswa kwakaomarara kune zviyo zvidiki kunowanzo shandiswa, nepo kuiswa kwakapfava kunoshandiswa kazhinji mukugadzira machining maitiro ane kucheka kwakavhiringwa, uko kunodaidzira kushoma, kusimba kwekuisa zvinhu. Huyero yecobalt kune tungsten carbide inokanganisawo carbide inserts 'kuoma mazinga; cobalt yakapfava, saka kana yakawanda cobalt yakaiswa, inopfava.

Tungsten carbide insert injinjini yakasarudza kuti ndeipi nhanho yekuomarara inoda kuwanikwa; nzira yekugadzira inotanga neupfu mbishi. Hupfu tungsten, cobalt uye kabhoni zvinogayiwa uye zvinosanganiswa pamwe chete nedoro nemvura, zvichigadzira gobvu slurry. Ichi chinhu chinoiswa muomesi, iyo inofefetedza zvinwiwa, ichisiya hupfu hwakanyatsosanganiswa. Carbide inoisa inozoitwa sintering process umo inosanganiswa nepolymer kugadzira paste, yakatsikirirwa mukuisa-yakaita mafiri uye inoiswa muchoto chinopisa kwazvo kuti chipiswe. Iyo polymer inonyungudutswa kunze kwekuiswa panguva iyi nhanho, uye iyo inoiswa inoderera.

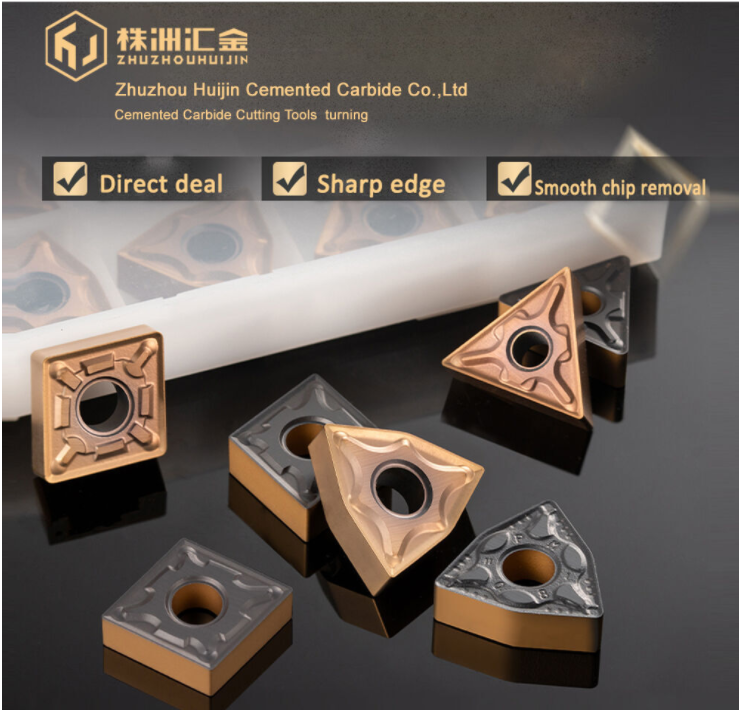

Tungsten carbide yekucheka maturusi anoiswa zvinhu zvinotsiviwa zvekucheka maturusi anowanzo kunge ane iwo chaiwo ekucheka. Kucheka maturusi ekuisa maapplication anosanganisira kufinha, kuvaka, cutoff uye kupatsanura, kuchera, grooving, hobbing, kugaya, migodhi, sawing, kuveura uye kucheka, kubaya, kupinza, kutenderedza, uye brake rotor kutendeuka.

Kutumira nguva: 2023-10-26