Kuumbwa kwekuongorora kwecemented carbide kuisa

Sezvinei zvese zvakagadzirwa nevanhu, kugadzirwa kwesimbi inorema yekucheka blade kunofanirwa kutanga kugadzirisa dambudziko rezvigadzirwa, ndiko kuti, kuona kuumbwa uye fomula yezvigadzirwa zveblade. Mazhinji emablades anhasi akagadzirwa necemented carbide, iyo inonyanya kuumbwa netungsten carbide (WC) uye cobalt (Co). WC chimedu chakaoma mublade, uye Co inogona kushandiswa sebhainda kugadzira blade.

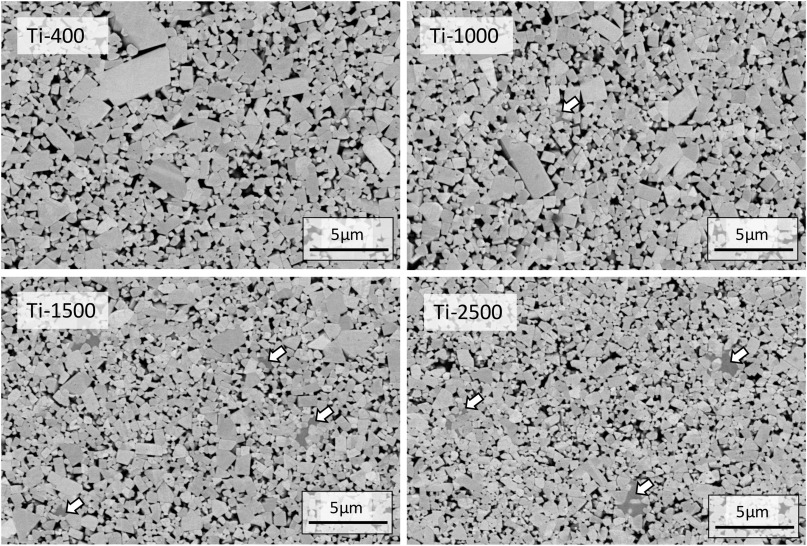

Nzira iri nyore yekushandura zvimiro zvecemented carbide ndeye kushandura saizi yezviyo zveWC zvimedu zvinoshandiswa. Huru hukuru hukuru (3-5 μ m) Kuomarara kwesimende carbide zvinhu zvakagadzirirwa neWC zvimedu zvine C% zvakaderera uye zviri nyore kupfeka; Diki diki saizi (< 1 μ m) WC zvimedu zvinogona kugadzira yakaoma alloy zvinhu nekuomarara kwepamusoro, zvirinani kupfeka kuramba, asiwo brittleness yakakura. Paunenge uchigadzira zvigadzirwa zvesimbi zvine kuoma kwakanyanya, kushandiswa kwezviyo zvakatsetseka semented carbide inoisa inogona kuwana yakanaka machining mhedzisiro. Nekune rimwe divi, coarse grain cemented carbide tool ine kuita zvirinani mukucheka kwepakati kana kumwe kugadzira kunoda kusimba kwechishandiso.

Imwe nzira yekudzora hunhu hwekuisa simende carbide ndeye kushandura chikamu cheWC kuita Co zvemukati. Kuenzaniswa neWC, kuoma kweCo kwakadzikira, asi kuoma kuri nani. Naizvozvo, kudzikisa zvirimo muCo kunozokonzera yakakwira kuomarara blade. Ehe, izvi zvakare zvinomutsa dambudziko rekuyera kwakazara - yakakwirira kuomarara mablades ane nani kupfeka kuramba, asi brittleness yavo zvakare yakakura. Zvinoenderana neiyo chaiyo yekugadzirisa mhando, kusarudza yakakodzera WC saizi yezviyo uye Co zvemukati reshiyo inoda ruzivo rwesainzi uye ruzivo rwakapfuma rwekugadzirisa.

Nekushandisa gradient zvinhu tekinoroji, kuwirirana pakati pesimba uye kuoma kweblade kunogona kudzivirirwa kusvika pamwero wakati. Iyi tekinoroji, iyo yakashandiswa zvakanyanya nevagadziri vezvishandiso zvikuru pasi rose, inosanganisira kushandiswa kweyero yepamusoro yeCo content muchikamu chekunze cheblade pane chemukati. Kunyanya zvakanyanya, iyo yekunze dhizaini (ukobvu 15-25 μ m) Wedzera Co zvemukati kupa basa rakafanana ne "buffer zone", kuitira kuti blade igone kumira kune imwe mhedzisiro pasina kuputika. Izvi zvinogonesa chishandiso chemuviri weblade kuwana akasiyana siyana zvivakwa zvinogona kuwanikwa chete nekushandisa simende carbide ine simba rakakwirira.

Kamwe chete saizi yechikamu, kuumbwa uye mamwe ehunyanzvi ma parameter ezvigadzirwa zvakatemwa, iyo chaiyo yekugadzira maitiro ekucheka anoisa anogona kutangwa. Chekutanga, isa hupfu hwetungsten hunoenderana, hupfu hwekabhoni uye hupfu hwecobalt muguyo rinenge saizi yakaenzana nemuchina wekugeza, geya hupfu kusvika pakukura kunodiwa, uye sanganisa marudzi ese ezvishandiso zvakaenzana. Panguva yekugaya, doro nemvura zvinowedzerwa kugadzirira gobvu dema slurry. Zvadaro slurry inoiswa mudutu rekuomesa, uye mvura iri muslurry inoputika kuti iwane lumpy poda uye inochengetwa.

Muchiitiko chinotevera chekugadzirira, iyo prototype yeblade inogona kuwanikwa. Kutanga, poda yakagadzirwa inosanganiswa ne polyethylene glycol (PEG). Se plasticizer, PEG inogona kubatanidza hupfu pamwe chete sehupfu. Nyaya yacho inobva yatsindirwa kuita blade mudhiya. Zvinoenderana neakasiyana nzira dzekutsikirira blade, single axis press inogona kushandiswa kudzvanya, kana multi axis press inogona kushandiswa kudzvanya chimiro cheblade kubva kumakona akasiyana.

Mushure mekuwana iyo yakatsikirirwa isina chinhu, inoiswa muchoto chikuru chekupisa uye yakanyungudutswa pakupisa kwakanyanya. Mukuita sintering, PEG inonyungudutswa uye inobudiswa kubva mumusanganiswa webillet, ichisiya semi-yakapedzwa simende ye carbide blade. Kana PEG yanyungudutswa, blade inodzika kusvika kune * saizi yayo yekupedzisira. Iyi nhanho yekuita inoda kwakaringana kuverenga kwemasvomhu, nekuti kudonha kweblade kwakasiyana zvichienderana neakasiyana maumbirwo ezvinyorwa uye reshiyo, uye kushivirira kwedimensional kwechigadzirwa chakapedzwa kunodiwa kudzorwa mukati memamicrons akati wandei.

Kutumira nguva: 2023-01-15