- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

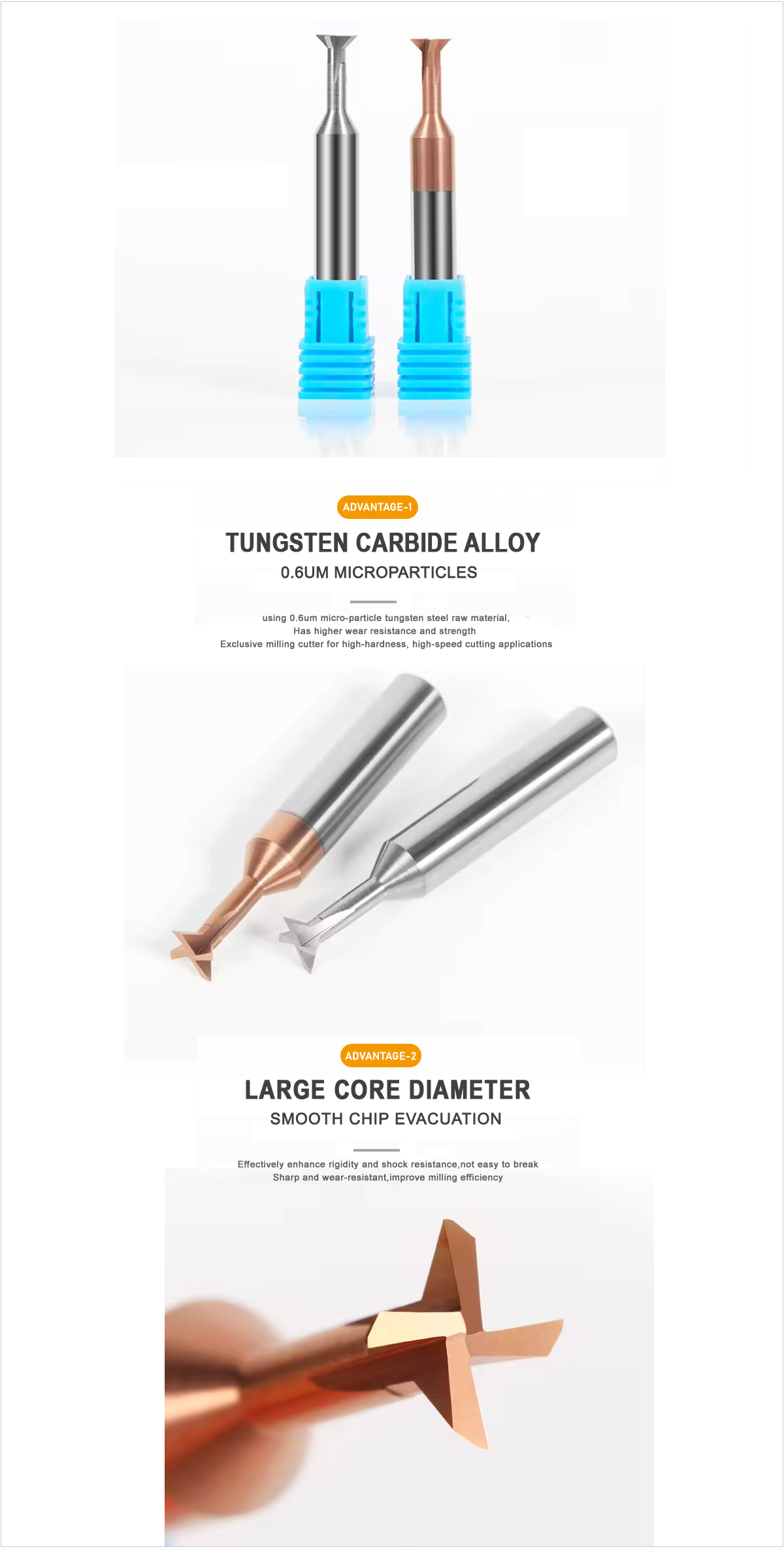

Customized CNC Non-standard Solid Carbide Dovetail Fausia Endmill T-slot Milling Cutter

CNC Meafaigaluega Uamea Alumini Dovetail Groove Cutter T Slot

4 pito fa'alupe fa'a'oti vili

Fa'aaufa'atasi E le fa'ata'ita'ia Fa'au'u Fa'au'u Mili tipi

Fa'apitoa i le gaosiga o le T-ituaiga fa'aleaganu'u Tungsten u'amea Cnc Dovetail

| Igoa | Fa'alava Fa'asu'u Fa'asolo T Slot T-Slot T-Milling Cutter |

| Mea | carbide sima |

| Ufiufi | AITiN/customized |

| Angle | 30°/45°/60°/90° |

| Aotelega umi | 50-60mm poʻo faʻapitoa |

| Talafeagai Mo | Uamea uamea, Uamea Carbon, Uamea fa'ameamea, Uamea lafo,alumini |

| Fa'atatauga | Su'ega vili pito, fa'a-T, fa'asolo loloto, vili va'alele |

| Fa'amatalaga uma. e mafai ona fa'atulagaina | |

O matou tulaga lelei:

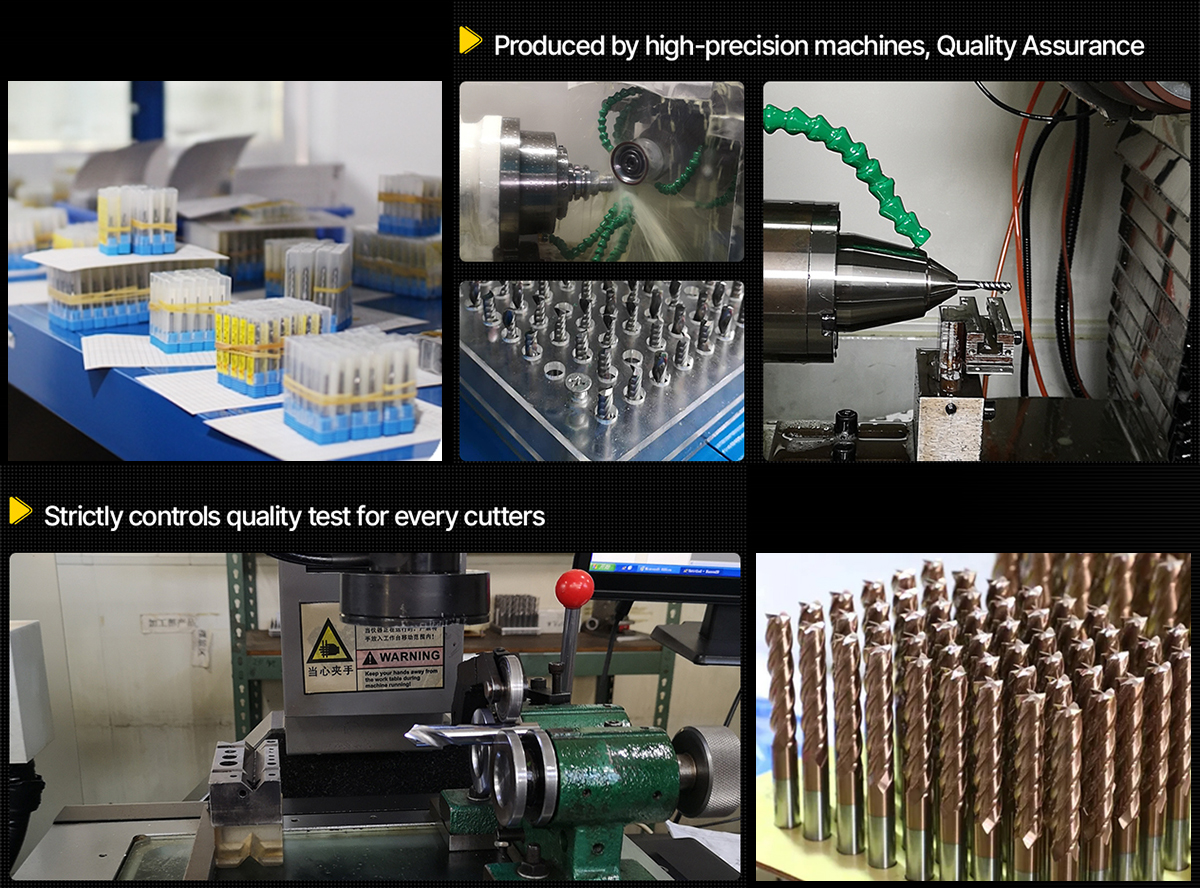

Au faʻapolofesa mo le gaosiga: Ia sili atu ma le 10 tausaga le poto masani mo le gaosiga i luga o le carbide faila.

Faʻasalalau vave e faʻavae i luga ole gaosiga maualuga gafatia.

Fa'atonuga lelei faiga: Fa'amautinoa a tatou oloa i tulaga lelei ma mautu.

Maua poto masani i oloa fa'apitoa.

Lagolago fa'apitoa: Fesoasoani ia te oe e maua le fofo sili.

T-slot Dovetail End Mills

O nei tipi faʻapitoa e gaosia e masini faʻaonaponei faʻaonaponei ma metotia, e mafai ai e a matou tagata faʻatau ona maua le poto masani T slotting. E mana'omia le uuina ma le sa'o lelei o meafaigaluega e alofia ai le gau. O oloa faʻatasi ma le faʻapipiʻiina e mo le gaosiga o uʻamea ma avanoa mo le alumini.

Fa'apolofesa Carbide End Mill Gaosi

Tele (tulaga masani & le masani)

Tulaga masani:

a matou tipi carbide faʻataʻitaʻiina e ufiufi ai le lautele mai le 2mm i le 12mm faʻafeiloaʻi le pulega o gaosiga faʻavaomalo ma tulaga lelei.

E le masani:

E mafai e la matou fale gaosi oloa ona gaosia oloa e le masani ai e pei o le ata tekonolosi poʻo faʻataʻitaʻiga.

Tele masani:

| Fa'amatalaga | ||||||

| Ole mita ole Mill D1/(mm) | Angle | Maualuluga Mill H/(mm) | Aloese Diamita d/(mm) | Umi ole ua h/(mm) | Laumepa Laupapa D2/(mm) | Aotelega Umi L/(mm) |

| 2 | 60 | 0.32 | 0.9 | 4 | 4 | 50 |

| 3 | 60 | 0.47 | 1.4 | 6 | 4 | 50 |

| 4 | 60 | 0.62 | 1.9 | 8 | 4 | 50 |

| 5 | 60 | 0.79 | 2.3 | 10 | 6 | 50 |

| 6 | 60 | 0.94 | 2.8 | 10 | 6 | 50 |

| 8 | 60 | 1.29 | 3.6 | 12 | 8 | 60 |

| 10 | 60 | 1.61 | 4.5 | 15 | 10 | 60 |

| 12 | 60 | 1.94 | 5.4 | 18 | 12 | 60 |

| 2 | 45 | 0.55 | 0.9 | 4 | 4 | 50 |

| 3 | 45 | 0.8 | 1.4 | 6 | 4 | 50 |

| 4 | 45 | 1.05 | 1.9 | 8 | 4 | 50 |

| 5 | 45 | 1.35 | 2.3 | 10 | 6 | 50 |

| 6 | 45 | 1.6 | 2.8 | 10 | 6 | 50 |

| 8 | 45 | 2.2 | 3.6 | 12 | 8 | 60 |

| 10 | 45 | 2.75 | 4.5 | 15 | 10 | 60 |

| 12 | 45 | 3.3 | 5.4 | 18 | 12 | 60 |

| 2 | 30 | 0.96 | 0.9 | 4 | 4 | 50 |

| 3 | 30 | 1.4 | 1.4 | 6 | 4 | 50 |

| 4 | 30 | 1.84 | 1.9 | 8 | 4 | 50 |

| 5 | 30 | 2.37 | 2.3 | 10 | 6 | 50 |

| 6 | 30 | 2.81 | 2.8 | 10 | 6 | 50 |

| 8 | 30 | 3.86 | 3.6 | 12 | 8 | 60 |

| 10 | 30 | 4.82 | 4.5 | 15 | 10 | 60 |

| 12 | 30 | 5.79 | 5.4 | 18 | 12 | 60 |

O loʻo i ai i le kamupani se laʻau atoa gaosiga o meafaigaluega gaosiga laina mai le paʻu o mea mataʻu sauniuniga, faʻapipiʻi, oomiina, sintering mamafa, olo, faʻapipiʻi ma faʻapipiʻi pe a maeʻa togafitiga. O loʻo taulaʻi i le suʻesuʻega ma le faʻafouina o mea faʻavae, fausaga faʻapipiʻi, faʻapipiʻi saʻo ma le faʻapipiʻiina o luga ole carbide NC faʻapipiʻi, ma faʻaleleia pea le faʻaogaina o masini, ola tautua ma isi mea tipiina o faʻapipiʻi NC carbide. A maeʻa le sili atu ma le sefulu tausaga o suʻesuʻega faʻasaienisi ma faʻafouga, ua faʻatautaia e le kamupani le tele o tekinolosi faʻapitoa tutoʻatasi, ei ai le R & D tutoʻatasi ma le gafatia o mamanu, ma e mafai ona tuʻuina atu faʻasalalauga faʻapitoa mo tagata faʻatau taʻitasi.