- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

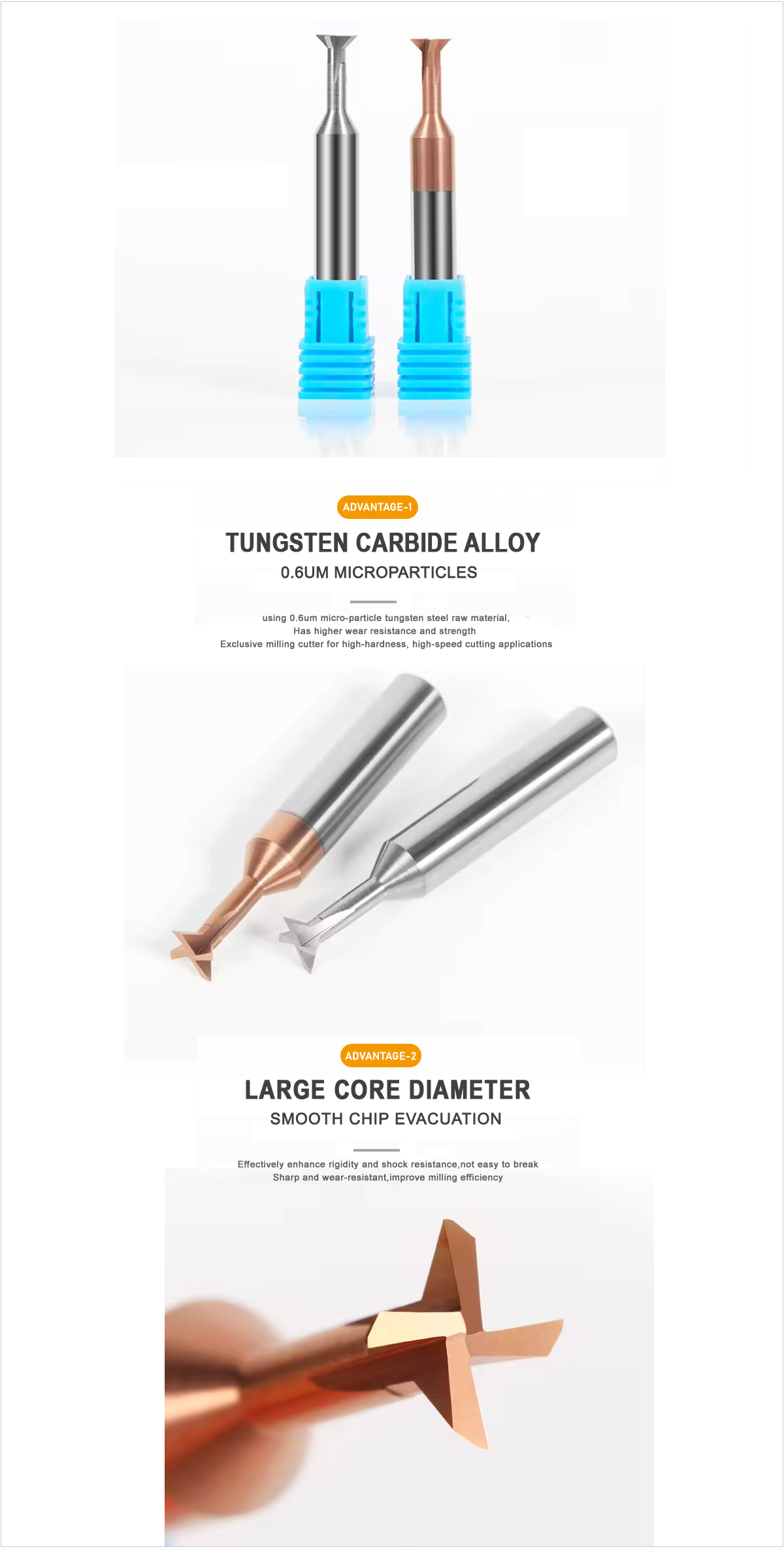

Customized CNC Non-standard Solid Carbide Dovetail Forming Endmill T-slot Milling Cutter

CNC Tools Steel Aluminum Dovetail Groove Cutter T Slot

4-edge dovetail milling cutter

Customized Non-standard Dovetail End Milling Cutter

Specializes in The Production of Custom Non-standard T-type Dovetail Cnc Tungsten Steel

| Name | Dovetail Groove Trough T Slot T-Slot T-Milling Cutter |

| Material | Cemented carbide |

| Coating | AITiN/customized |

| Angle | 30°/45°/60°/90° |

| Overall length | 50-60mm or customized |

| Suitable For | Stainless steel, Carbon Steel, Mould steel, Cast Iron,aluminum |

| Application | Side milling slotting, T-shaped slotting, deep slotting, plane milling |

| All the specs. can be customized | |

Our advantages:

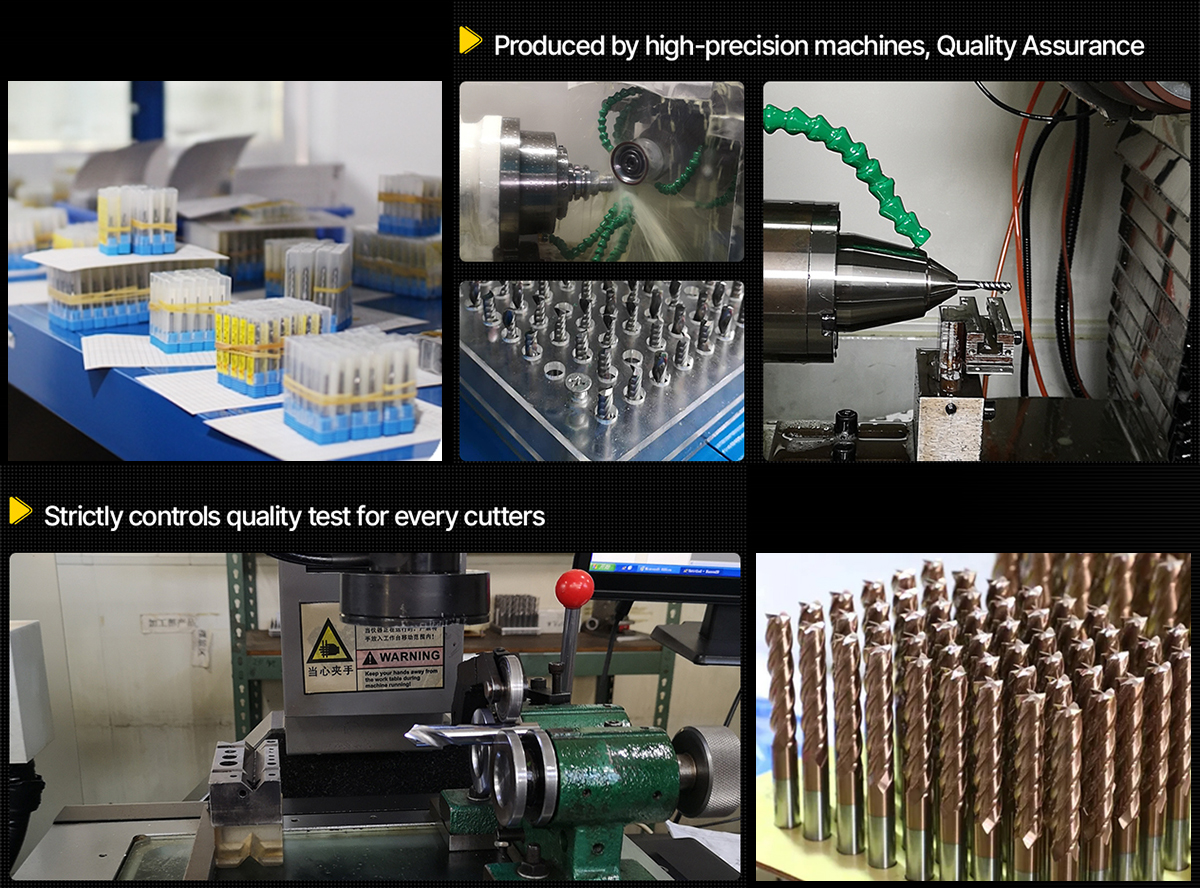

Professional team for production: Have more than 10 years experience for production on carbide filed.

Fast delivery based on high production capability.

Strict quality control system: Ensure our product in good and stable quality.

Rich experience on customized products.

Technical support: Help you get the best solution.

T-slot Dovetail End Mills

This special cutters is manufactured by state-of-art machines and techniques, enable our clients have good T slotting experience. It require rigid tool holding and run properly to avoid breakage. Product with coating is for steel processing and blank ones for aluminum.

Professional Carbide End mill Manufacture

Size (standard & non-standard)

Standard:

our standard carbide milling cutters cover the diameter range from 2mm to 12mm meeting the international manufacturing management and quality standards

Non-Standard:

Our factory can manufacture the non-standard products as per the technology drawing or samples.

Regular size:

| Specification | ||||||

| Mill Diameter D1/(mm) | Angle | Mill Height H/(mm) | Avoidance Diameter d/(mm) | Neck Length h/(mm) | Shank Diameter D2/(mm) | Overall Length L/(mm) |

| 2 | 60 | 0.32 | 0.9 | 4 | 4 | 50 |

| 3 | 60 | 0.47 | 1.4 | 6 | 4 | 50 |

| 4 | 60 | 0.62 | 1.9 | 8 | 4 | 50 |

| 5 | 60 | 0.79 | 2.3 | 10 | 6 | 50 |

| 6 | 60 | 0.94 | 2.8 | 10 | 6 | 50 |

| 8 | 60 | 1.29 | 3.6 | 12 | 8 | 60 |

| 10 | 60 | 1.61 | 4.5 | 15 | 10 | 60 |

| 12 | 60 | 1.94 | 5.4 | 18 | 12 | 60 |

| 2 | 45 | 0.55 | 0.9 | 4 | 4 | 50 |

| 3 | 45 | 0.8 | 1.4 | 6 | 4 | 50 |

| 4 | 45 | 1.05 | 1.9 | 8 | 4 | 50 |

| 5 | 45 | 1.35 | 2.3 | 10 | 6 | 50 |

| 6 | 45 | 1.6 | 2.8 | 10 | 6 | 50 |

| 8 | 45 | 2.2 | 3.6 | 12 | 8 | 60 |

| 10 | 45 | 2.75 | 4.5 | 15 | 10 | 60 |

| 12 | 45 | 3.3 | 5.4 | 18 | 12 | 60 |

| 2 | 30 | 0.96 | 0.9 | 4 | 4 | 50 |

| 3 | 30 | 1.4 | 1.4 | 6 | 4 | 50 |

| 4 | 30 | 1.84 | 1.9 | 8 | 4 | 50 |

| 5 | 30 | 2.37 | 2.3 | 10 | 6 | 50 |

| 6 | 30 | 2.81 | 2.8 | 10 | 6 | 50 |

| 8 | 30 | 3.86 | 3.6 | 12 | 8 | 60 |

| 10 | 30 | 4.82 | 4.5 | 15 | 10 | 60 |

| 12 | 30 | 5.79 | 5.4 | 18 | 12 | 60 |

The company has a complete blade manufacturing process equipment production line from powder raw material preparation, mold making, pressing, pressure sintering, grinding, coating and coating post-treatment. It focuses on the research and innovation of the base material, groove structure, precision forming and surface coating of carbide NC inserts, and constantly improves the machining efficiency, service life and other cutting properties of carbide NC inserts. After more than ten years of scientific research and innovation, the company has mastered a number of independent core technologies, has independent R&D and design capabilities, and can provide customized production for each customer.