- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

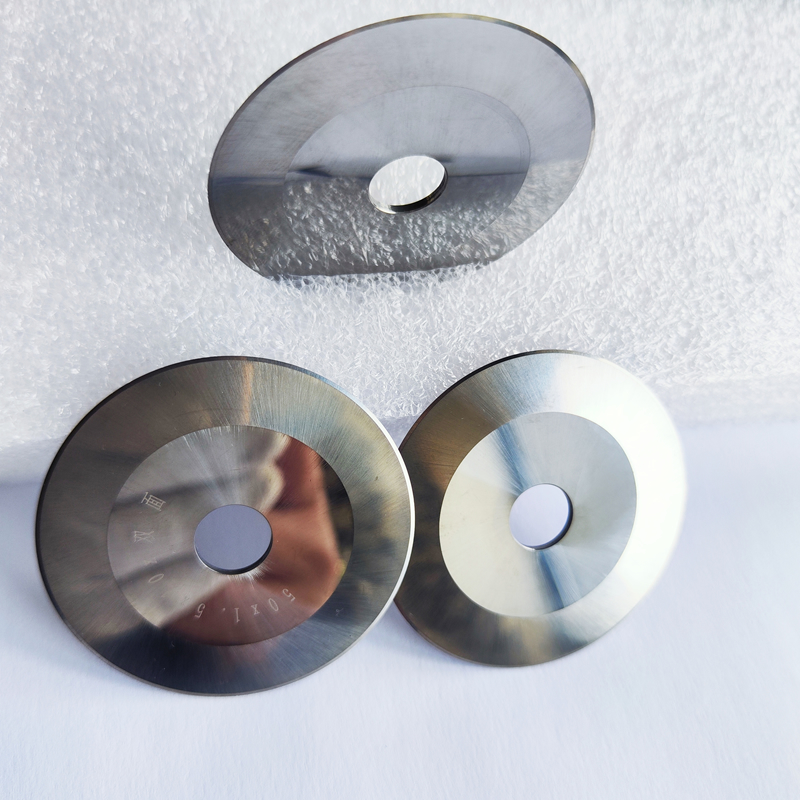

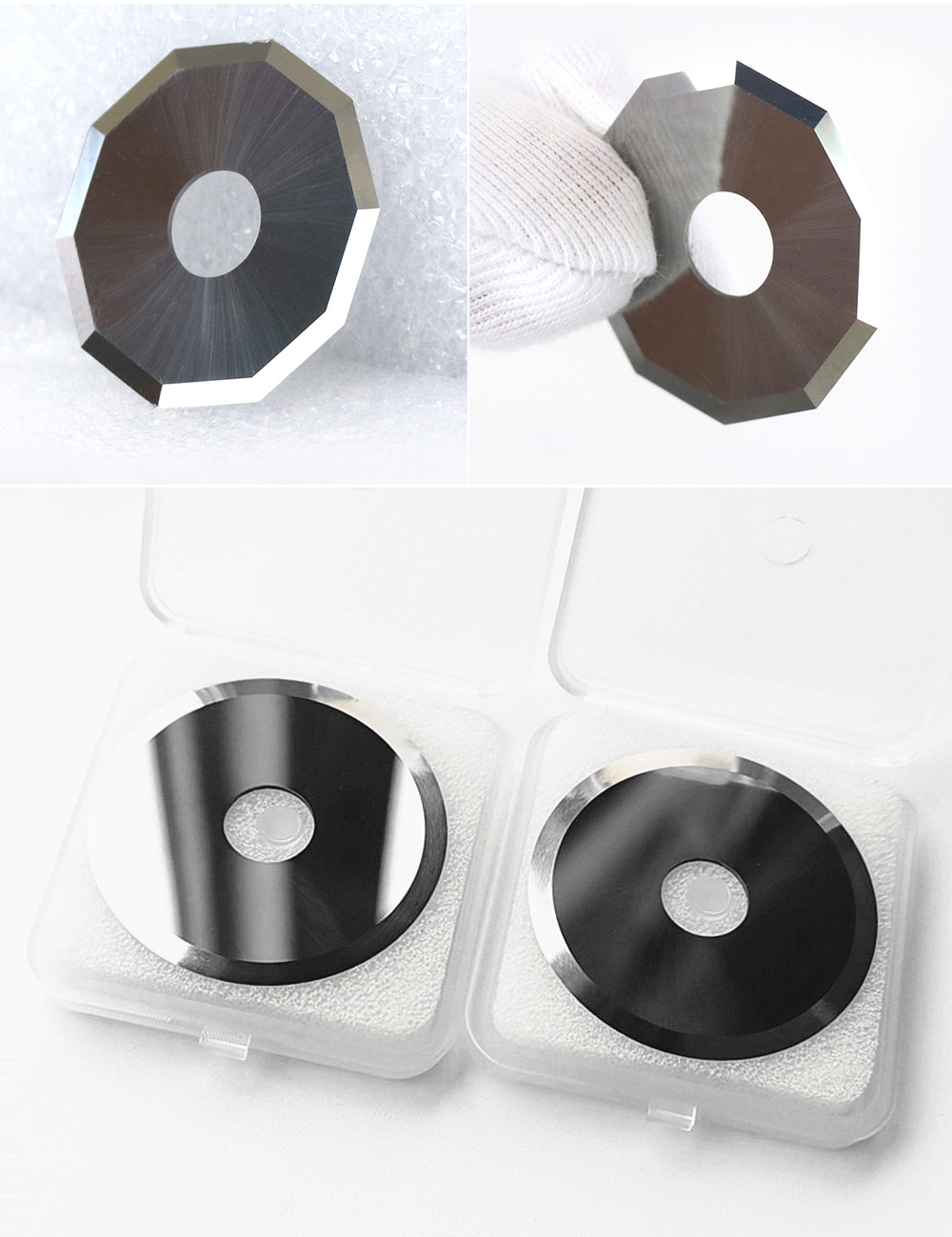

circular ultra fine sub micron grain cemented carbide blades

circular ultra fine sub micron grain cemented carbide blades

Service : OEM and ODM

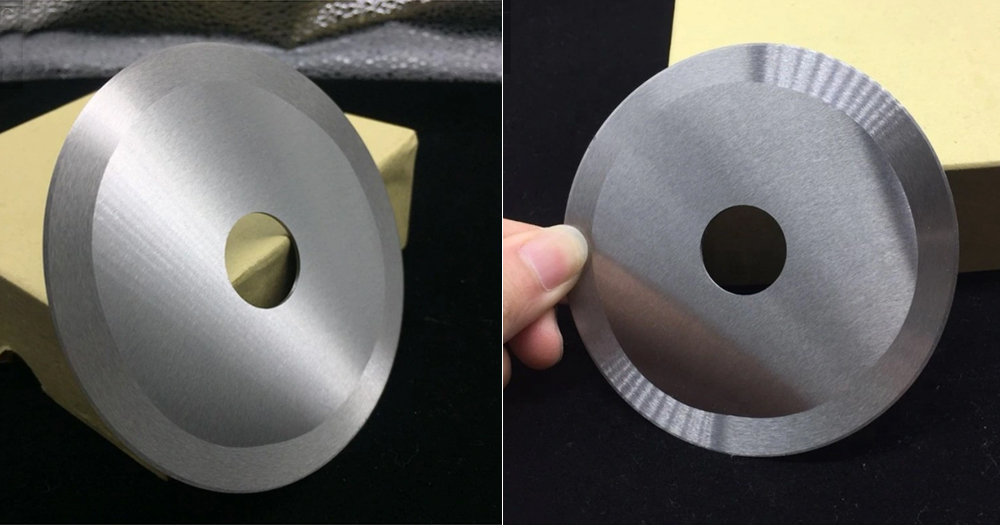

Application: weft cutter of hard yarn for weaving loom machines

Surface: with superior razor sharp edge quality and mirror surface and edge polish

hardness: 92 HRA

Products Description

cemented carbide tungsten steel round blade product advantage:

1.Smooth surface, high-precision grinding of cutting edges

2.Smooth cutting of sharp blades without burrs

3.Chip removal is more smoother

4.High-precision mirror grinding technology, chip removal is smooth, not easy to break the tip, and no chipping

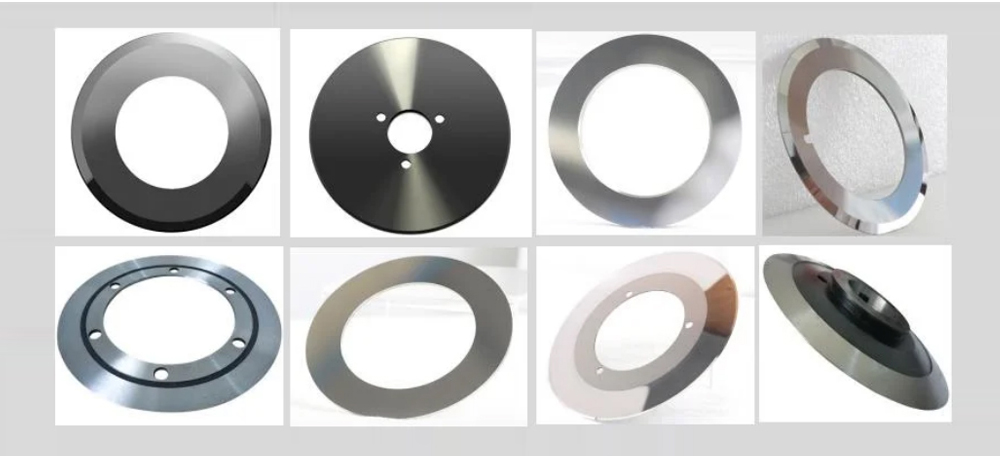

5.Customized Products are available.

We produce not only the standard items, but also the customized terms according to drawing.

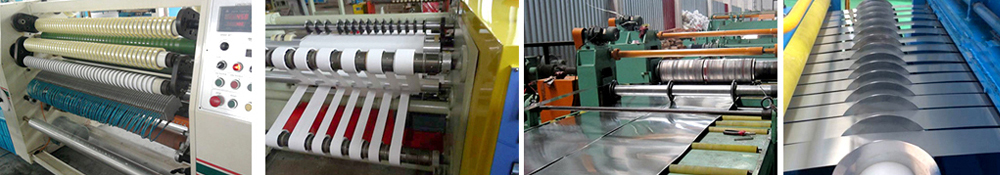

What is our carbide blade application?

The carbide circular blades for Slitting Corrugated Board, carbide rotary blade for rubbers cutting, carbide blade for

battery industry, carbide blades for Tobacco Machines, carbide circuit board cutting knife, carbide blades for metal

cutting, carbide knife for Rewinder machines, carbide blades for chemical fiber cutting, carbide blades for

printing industry, carbide milling cutter for paper industry, and carbide blades for other special range.

Our advantages:

1. Our Cutting Knives and Discs can be supplied with either a standard ground or highly polished cutting

edge depending on the material to be cut and/or the lifetime required of the tool.

2. Our dedicated team of technical project managers are all highly qualified and experienced. We can help to

develop the cutting profile and product best suited to your needs.

3. Our careful selection of materials the life of existing knives can be extended to reduce the downtime of tooling changes.

Let our experience take the guess work out of the job of specifying the most suitable product for your purpose.

Whatever you are cutting, use huijin Carbide Tools for reliable, professional service and high quality products.

Quality control:

1.All raw materials are tested in terms of density, hardness and TRS before use

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

material grade :

| Grade | Grain size (um) | Cobalt content (100%) | Density (g/cm3) | Hardness (HRA) | T.R.S (N/mm2) |

| YG6X | 0.8-1.2 | 6 | 14.8 | 91 | 2000 |

| YG10X | 0.8-1.2 | 10 | 14.42 | 91.8 | 4000 |

| YG12X | 0.8-1.2 | 12 | 14.5 | 89.5 | 2600 |

| Material grade | Tungsten Carbide YG10X, YG13X, OEM | |||

| Thickness | 0.2-6mm or customized | |||

| Flatness | 0.003mm | |||

| Type of edge | single edge, double edge | |||

| HRA | 85-93 | |||

| Straightness | <0.1 | |||

| Surface roughness | Ra0.2 | |||

| Laser engraving | Done as requirement | |||

| Package | 4 pcs/set,Simple packing/Plastic box packing/Blister packing | |||

| Main Size | OD(mm) | ID(mm) | Thickness(mm) | Cutting Edge |

| 300 | 112 | 1.4 | double | |

| 280 | 168 | 1.4 | double | |

| 265 | 112 | 1.3 | double | |

| 260 | 168 | 1.4 | double | |

| 260 | 140 | 1.4 | double | |

| 240 | 132 | 1.2 | double | |

| 230 | 110 | 1.3 | double | |

| 140 | 46 | 0.5 | single | |

| 100 | 16 | 0.3 | single | |

| 85 | 16 | 0.25 | single | |

| 60 | 19 | 0.27 | single | |

| Size | Can be customized according to customer requirements | |||

| Advantages | 1, High quality raw materials. | |||

| 2. Durable & Long service life. | ||||

| 3. High precision. | ||||

| 4. Nice and solid packaging. | ||||

| 5. Excellent weather resistance and waterproof. | ||||

| Application | For paperboard/paper/cardboard/carton/Tobacco machine to cut. | |||

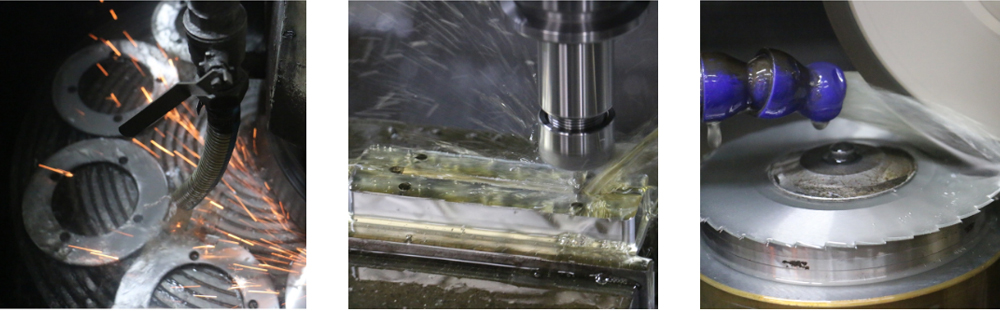

The company has a complete blade manufacturing process equipment production line from powder raw material preparation, mold making, pressing, pressure sintering, grinding, coating and coating post-treatment. It focuses on the research and innovation of the base material, groove structure, precision forming and surface coating of carbide NC inserts, and constantly improves the machining efficiency, service life and other cutting properties of carbide NC inserts. After more than ten years of scientific research and innovation, the company has mastered a number of independent core technologies, has independent R&D and design capabilities, and can provide customized production for each customer.