- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

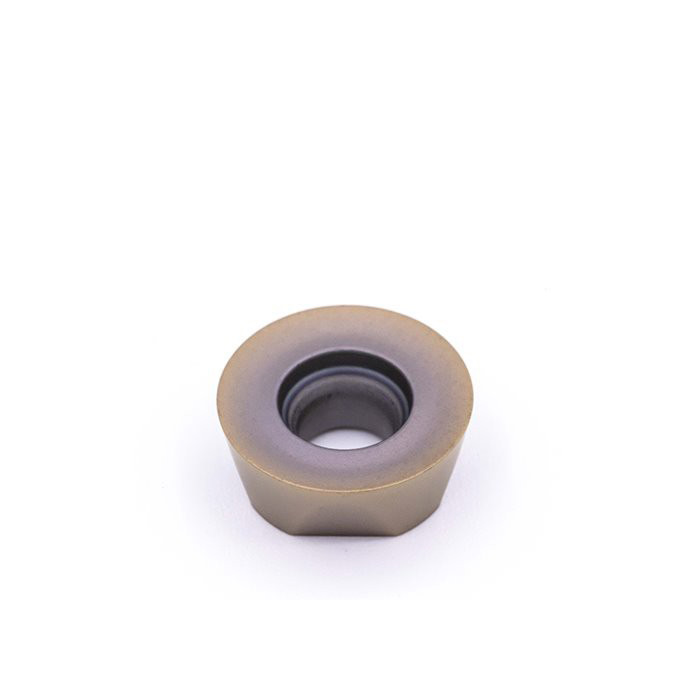

Profile milling inserts

RPMT Insert

Product name: RPMT insert

Series: RPMT

Chip-Breakers: JSM/GM

Product Information:

Profile milling is a common milling operation.

RPMT insert is one kind of profile milling insert with strong cutting edges, best reliability and long endurance.

R - Round shape of turning insert.

P - Insert with clearance under main cutting edge (11°).

M - Tolerances and dimensions of carbide turning insert.

T - Hole through insert and single sided chip breaker.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD | PVD | |||||||||

JK3020 | JK3040 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1520 | JR1525 | JR1028 | JR1330 | |||

RPMT08T2MOE-JSM | 1.00-1.30 | 0.05-0.25 | • | • | O | O | |||||||

RPMT10T3MOE-JSM | 1.50-4.00 | 0.05-0.30 | • | • | O | O | |||||||

RPMT1204MOE-JSM | 1.50-5.00 | 0.05-0.35 | • | • | O | O | |||||||

RPMT1606MOE-JSM | 2.00-6.50 | 0.10-0.40 | • | • | O | O | |||||||

RPMT08T2MO-GM | 1.50-4.00 | 0.10-0.30 | • | • | O | O | |||||||

RPMT10T3MO-GM | 1.80-5.00 | 0.10-0.50 | • | • | O | O | |||||||

RPMT1204MO-GM | 2.00-6.50 | 0.10-0.50 | • | • | O | O | |||||||

RPMT08T2MO | 1.5-4.0 | 0.1-0.3 | • | • | O | O | |||||||

RPMT10T3MO | 1.8-5.0 | 0.1-0.5 | • | • | O | O | |||||||

RPMT1204MO | 2-6.5 | 0.1-0.5 | • | • | O | O | |||||||

• : Recommended Grade

O: Optional Grade

Application:

Round inserts and concepts with radius are milling cutters used for roughing and semi-roughing while ball nose End mills are milling cutters used for finishing and super-finishing.

Recommend for roughing, semi-roughing, semi-finishing and finishing of steel, stainless steel, cast iron and super alloys.

The company has a complete blade manufacturing process equipment production line from powder raw material preparation, mold making, pressing, pressure sintering, grinding, coating and coating post-treatment. It focuses on the research and innovation of the base material, groove structure, precision forming and surface coating of carbide NC inserts, and constantly improves the machining efficiency, service life and other cutting properties of carbide NC inserts. After more than ten years of scientific research and innovation, the company has mastered a number of independent core technologies, has independent R&D and design capabilities, and can provide customized production for each customer.