- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

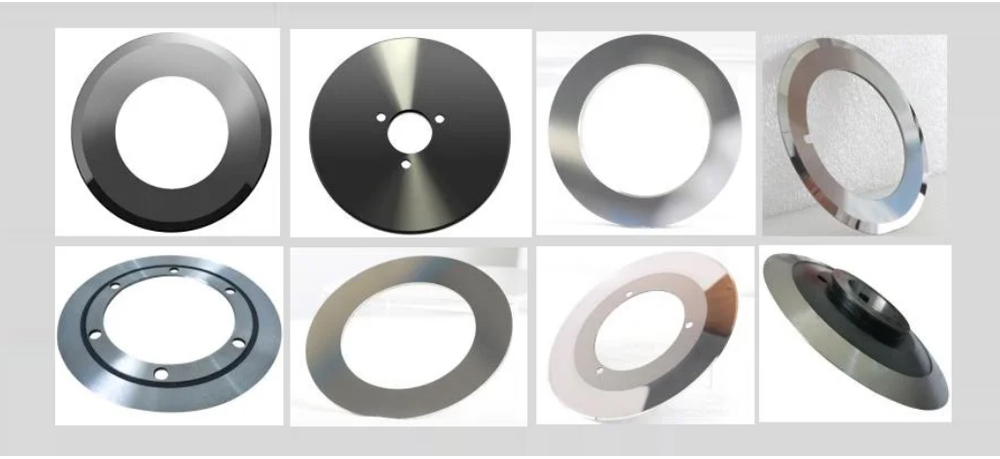

Custom carbide round cutter

Custom carbide round cutter

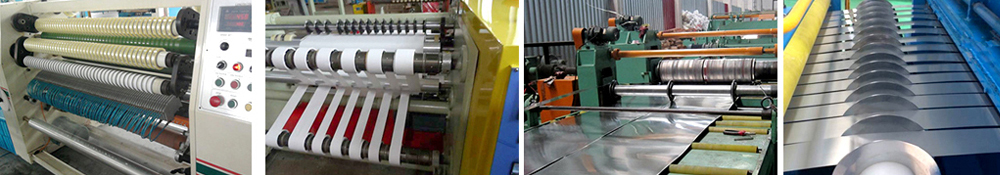

Widely used in: glasses, watches, machinery, electronics, motors, leather and other industries

Working type: Cutting / slotting

Surface: grinding and polishing to mirror

Service : OEM and ODM

Customized NON-Standard inserts OEM service:

1. We provide unmatched experience and customer service with complete confidentiality. We have a proven

track record of over 15+ years in the carbide inserts manufacturing industry.

2. Our OEM services pair your blueprints and designs with manufacturing capabilities to make your product a reality.

3. Any products - any design - any compliance - any industry,small - medium - high quantities are welcome.

4.If you have specialize request, you can provide specifications of what you need in detail, files in CAD or

sample please sent to sales@zzhardmetals.com.

OEM Process:

1. Free design.

2. Free samples test.

3. Determination of cutting data and calculation of machining times.

4. Calculation of machining costs per piece.

5. Projection of tooling costs per piece.

6. Calculation of performance (cutting forces, spindle power, torque moment).

7. Support during final acceptance and commissioning runs.

What you can expect from us:

1.Quick quotation .

2.Easy ordering .

3.Performance guarantee for given product and cutting data .

4.Competitive delivery times .

5.All major product groups within metalworking, e.g. turning, milling, and hole making, are available for

customization, giving you the freedom to specify your own dimensions without having to pay the price of a special tool.

Quality control:

1.All raw materials are tested in terms of density, hardness and TRS before use

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

The company has a complete blade manufacturing process equipment production line from powder raw material preparation, mold making, pressing, pressure sintering, grinding, coating and coating post-treatment. It focuses on the research and innovation of the base material, groove structure, precision forming and surface coating of carbide NC inserts, and constantly improves the machining efficiency, service life and other cutting properties of carbide NC inserts. After more than ten years of scientific research and innovation, the company has mastered a number of independent core technologies, has independent R&D and design capabilities, and can provide customized production for each customer.