- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

Corn Teeth CNC Router Bits Carbide End Mill Milling Drill PVC PCB Cutter

Carbide corn milling cutter

carbide corn Milling Cutter CNC Corn teeth end mill for PCB

Solid Carbide Corn Teeth End Mill In Milling Cutter For Carbon Fiber

carbide tungsten steel corn end mill cnc router bits

Carbide Milling Router Bits Engraving Cutters Cutting Tools

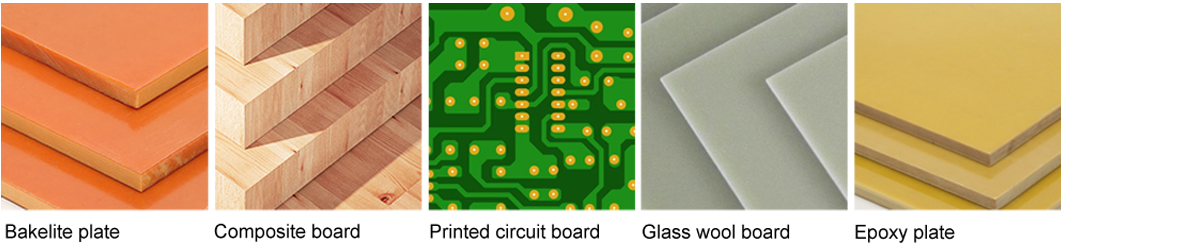

Carbide corn milling cutter application:

This carbide corn milling cutters is designed for processing PCB, normal FR-4, CEM-3 boards,circuit board,

carbon fiberglass, plastics, epoxy board, wood, stainless steel. Excellent chip removal performance

balance high wear resistance and bending strength can improve the productivity effectively!

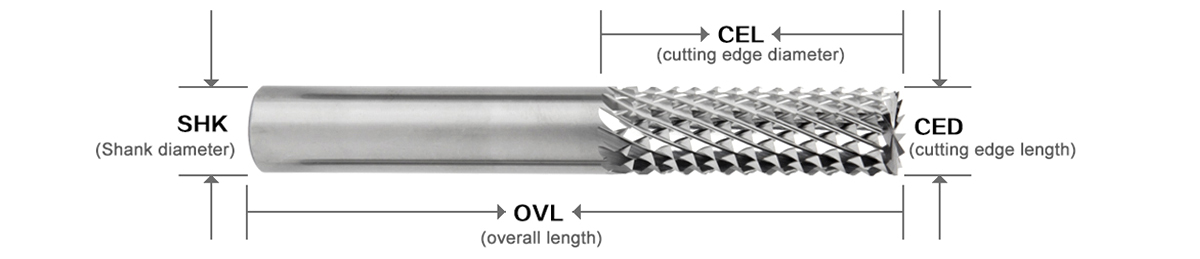

Product name | |

Material | Tungsten carbide |

Model | Standard |

Coating | Uncoated |

HRC | 55 |

Shank diameter | 3.175-12mm |

whole length | 38-100mm |

Application | for processing PCB, normal FR-4, CEM-3 boards,circuit board, carbon fiberglass, plastics, epoxy board, wood, stainless steel. |

Machine type | CNC Milling Machine, Engraving machine,High speed machine,etc |

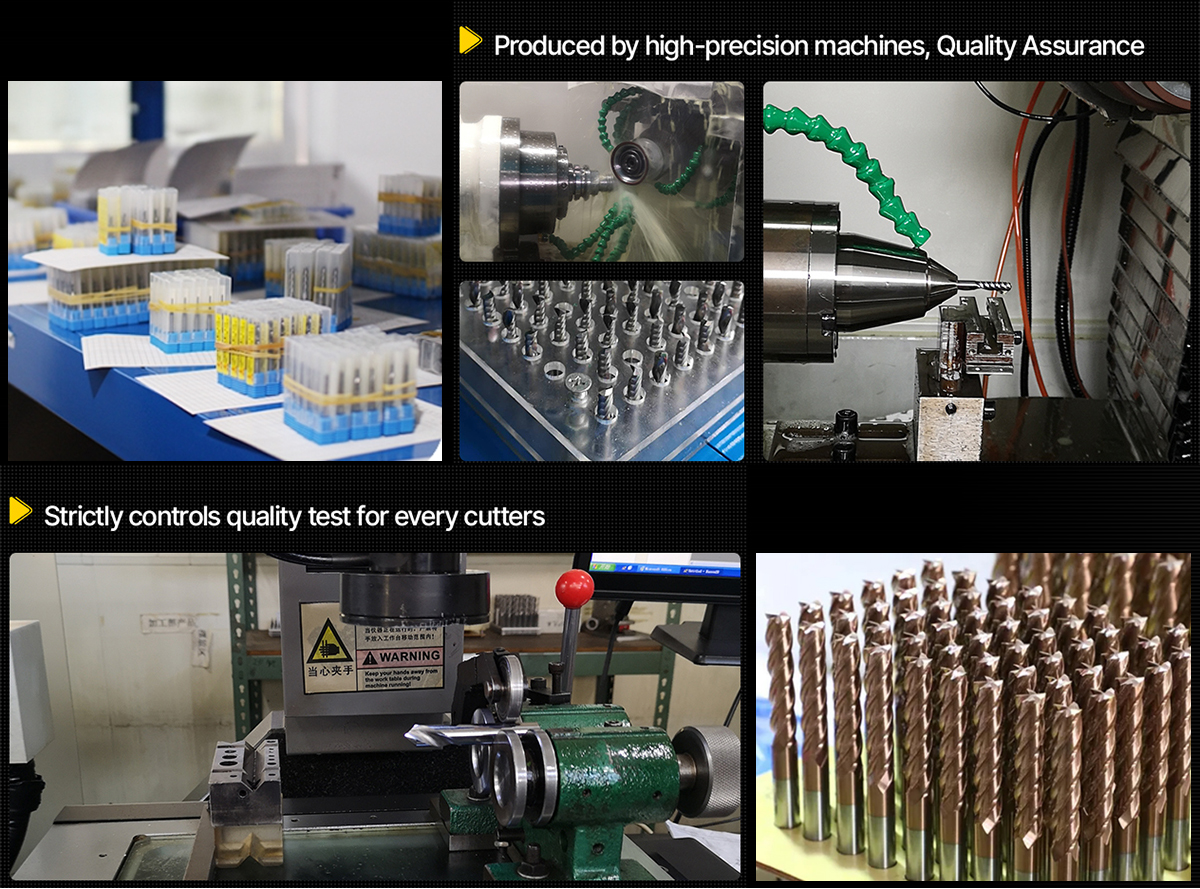

Professional Carbide End mill Manufacture

Size (standard & non-standard)

Standard:

our standard carbide milling cutters cover the diameter range from 1mm to 12mm meeting the international manufacturing management and quality standards

Non-Standard:

Our factory can manufacture the non-standard products as per the technology drawing or samples.

Regular size:

Carbide Corn Milling Cutter | |||

Mill Dia | LOC | Shank Dia | OAL |

1 | 7 | 3.175 | 38 |

1.5 | 8.5 | 3.175 | 38 |

2 | 10.5 | 3.175 | 38 |

2.5 | 10.5 | 3.175 | 38 |

3 | 12 | 3.175 | 38 |

3.175 | 12/15/17 | 3.175 | 38 |

3.175 | 22/25 | 3.175 | 45 |

4 | 12/15/17/22 | 4 | 45 |

4 | 25 | 4 | 50 |

4 | 28/32 | 4 | 60 |

5 | 22/25 | 5 | 50 |

6 | 17/22/25 | 6 | 50 |

6 | 32 | 6 | 60 |

6 | 42 | 6 | 70 |

6 | 52 | 6 | 85 |

8 | 22/25/32 | 8 | 50 |

8 | 32 | 8 | 60 |

8 | 52 | 8 | 80 |

10 | 25 | 10 | 60 |

10 | 32 | 10 | 75 |

10 | 50 | 10 | 100 |

12 | 32 | 12 | 75 |

12 | 50 | 12 | 100 |

-Express companies: DHL, FedEx, TNT, UPS, etc.

-Airlines.

-Ocean shipping

A. Standard packing

-Plastic boxes with foam inside and carton outside.

-Paper boxes with foam inside and carton outside.

-Inner boxes/packing material inside and plywood box outside (for heavy product).

The company has a complete blade manufacturing process equipment production line from powder raw material preparation, mold making, pressing, pressure sintering, grinding, coating and coating post-treatment. It focuses on the research and innovation of the base material, groove structure, precision forming and surface coating of carbide NC inserts, and constantly improves the machining efficiency, service life and other cutting properties of carbide NC inserts. After more than ten years of scientific research and innovation, the company has mastered a number of independent core technologies, has independent R&D and design capabilities, and can provide customized production for each customer.