- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

HJDK650 Tungsten carbide Center kubowola

Tungsten carbide Center kubowola

HJDK650 Tungsten carbide Center kubowola

Yoyenera kubowola chitsulo, chitsulo chosapanga dzimbiri, chitsulo choponyedwa, zinthu zopanda chitsulo.

Kulimba HRA92.8

Zida: tungsten carbide

Kubowola pakati pa HJDK650 mndandanda

Mawu enieni:

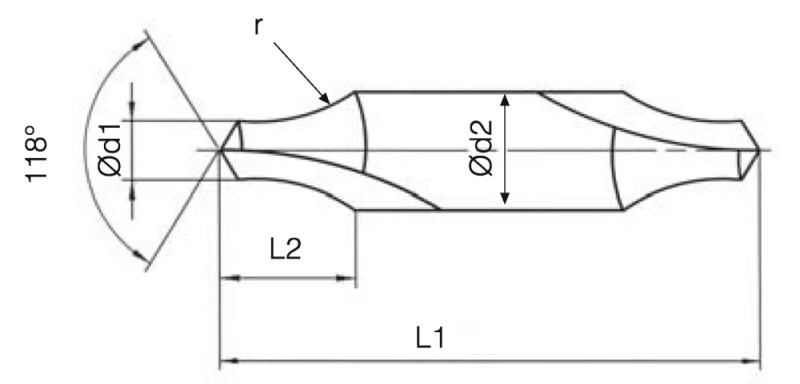

Kubowola kwapakati kwa HJDK650 kumazindikira kuphatikiza kwabwino pakati pa chip flow pagawo la kubowola ndi gawo la countersink. Zitoliro zawo zimatha kunyamula tchipisi tating'onoting'ono ndipo zimagwira ntchito bwino kuti zichotse chips. zobowola pakati zimakhala ndi mbali zonse ziwiri, komanso zimakhala ndi zitoliro zozungulira. Chifukwa cha ejection yabwino ya chip, zovuta zotere zimachepa ngati zida zimasweka chifukwa cha kutsekeka kwa chip. mphamvu, tachepetsa kutalika kwa kubowola. Kuonjezeranso kubwezera chofooka pa malo olumikizirana pakati pa kubowola ndi countersink, malo olumikizira amakhala ndi R omwe radius ili mkati mwa taper yakumbuyo ya kubowola. Amakhalanso ndi mzere waukulu.

Mawonekedwe:

Yoyenera kubowola chitsulo, chitsulo chosapanga dzimbiri, chitsulo choponyedwa, zinthu zopanda chitsulo.

Stub chisel, luso lodzipangira nokha.

Radial point, kukana kudula kochepa.

Lip chamfer, kuchuluka kwa chakudya, kuchita bwino kwambiri.

Kukula kokhazikika:HJDK650 Fine Powder Center Drill Series

| Kuitanitsa kodi | Diameter | ngodya | Kutalika kwa chitoliro | O.A.L. | Shank Dia. |

| HJDK650-0102 | 1 | 60° | 1.5 | 35 | 4 |

| HJDK650-0202 | 2 | 60° | 2.5 | 50 | 5 |

| HJDK650-0252 | 2.5 | 60° | 3 1 | 60 | 6.3 |

| HJDK650-03152 | 3.15 | 60° | 3.9 | 70 | 8 |

| HJDK650-0402 | 4 | 60° | 5 | 80 | 10 |

| HJDK650-0502 | 5 | 60° | 6.3 | 80 | 12 |

| HJDK650-0632 | 6.3 | 60° | 80 | 80 | 16 |

Kapangidwe ka zida:

1.Zinthu Zathupi:

A) Kulimba kuposa kapena kofanana ndi 92.8 HRA;

B) Kachulukidwe wamkulu kuposa kapena wofanana ndi 14.2 g/cm³;

C) TRS wamkulu kuposa kapena wofanana ndi 4200 N/mm²;

D) Zopanda gawo la ETA;

E) Palibe kuipitsidwa ndi zinthu zina;

F) Porosity = A00 / B00 / C00 ;

G) Kukula kwambewu kofanana komanso kosasinthasintha. Palibe kukula kwa njere komwe kungakhale kukulirapo kuposa momwe tafotokozera.

H) Chromium carbide grain growth inhibitor yokha.

2.Zida zonse zopangira, zokutira zimagwiritsidwa ntchito ku Germany, Switzerland, zida zopangira;

Ntchito parameter:

| Center kubowola ntchito parameter: | ||||||||||

| Workpeice zinthu | Kudula liwiro | Mtengo (mm/rev) | ||||||||

| (m/mphindi) | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D20 | ||

| Low carbon steel, long chip (<125HB) | 130 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.15 | 0.17 | 0.2 | 0.24 | 0.26 | 0.3 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.26 | 0.3 | 0.32 | 0.35 | 0.4 | 0.45 | ||

| Chitsulo cha carbon chochepa, chidule chachidule, chitsulo chodula chosavuta ( | 120 | 0.1 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.24 | 0.3 | 0.32 | 0.34 | 0.4 | 0.45 | ||

| Chitsulo cha mpweya carbon ndi medium carbon zitsulo ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Chitsulo cha aloyi, chitsulo ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Chitsulo cha aloyi, chitsulo (35-48HRC) | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| PH ndi ferritic, martensitic zitsulo ( | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Gray iron(<32HRC) | 140 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Aloyi iron ya medium processing zovuta, nodular cast iron ( | 130 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 105 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Chitsulo chosasunthika chapamwamba aloyi , chitsulo nodular cast ( | 120 | 0.1 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.28 | |

| 90 | 0.16 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.29 | ||

| 60 | 0.22 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.35 | ||

| Wopangidwa aluminiyamu aloyi (Si | 150 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Kuponya aluminium aloyi (Si | 150 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 120 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Kuponya aluminium aloyi (Si>12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| 12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

Copper, copper alloy (

Chenjerani:

Onetsetsani kuti chogwirira ntchito ndi makinawo ndi okhazikika ndipo amagwiritsa ntchito chogwirizira molondola, gwiritsani ntchito ma chuck a hydraulic chucks, ma collet chucks apamwamba kwambiri.

Onetsetsani kuti zonse zomwe zawonetsedwa (TIR) ndizochepera 0.02mm.

The analimbikitsa kudula chikhalidwe ndi oyenera ntchito madzi sungunuka.

Kampaniyo ili ndi mzere wathunthu wa zida zopangira zida zopangira zida zopangira ufa, kupanga nkhungu, kukanikiza, kuponderezana, kugaya, kupaka ndi kupaka pambuyo pochiritsa. Imayang'ana pa kafukufuku ndi kusinthika kwa zinthu zoyambira, kapangidwe ka groove, kupanga molondola komanso zokutira pamwamba pa zoyikapo za carbide NC, ndipo nthawi zonse kumapangitsa kuti makina azigwira bwino ntchito, moyo wautumiki ndi zina zodulira zoyika za carbide NC. Pambuyo pazaka zopitilira khumi za kafukufuku wasayansi ndi luso, kampaniyo yadziwa zambiri zamaukadaulo odziyimira pawokha, ili ndi R&D yodziyimira payokha komanso luso lakapangidwe, ndipo imatha kupereka zopanga makonda kwa kasitomala aliyense.